Alignment index forecasting method based on integration of quotient spaces and knowledge sources for photoetching process

A technology of index forecasting and knowledge source, which is applied in automation, information and advanced manufacturing fields, and can solve problems such as product rework and inaccurate engraving of lithography equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

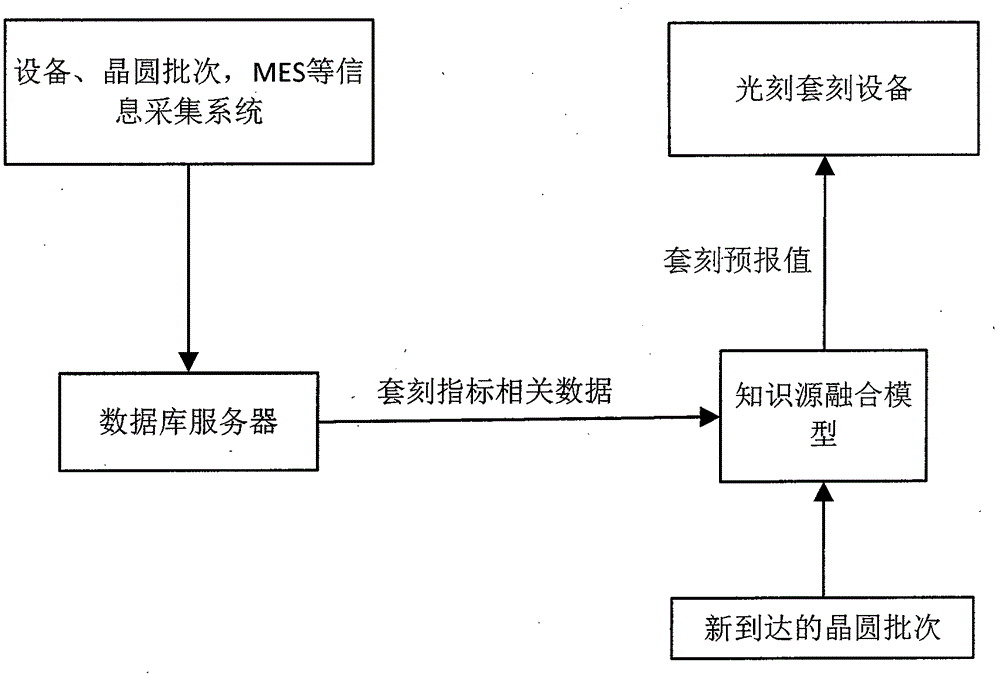

[0073] The overlay index forecasting method of the present invention depends on the relevant data acquisition system, which includes an MES system and a database server. A schematic diagram of the software and hardware architecture of the present invention applied in the photolithographic overlay process of the actual microelectronics production line is as follows: figure 1 As shown, the embodiments of the present invention are as follows.

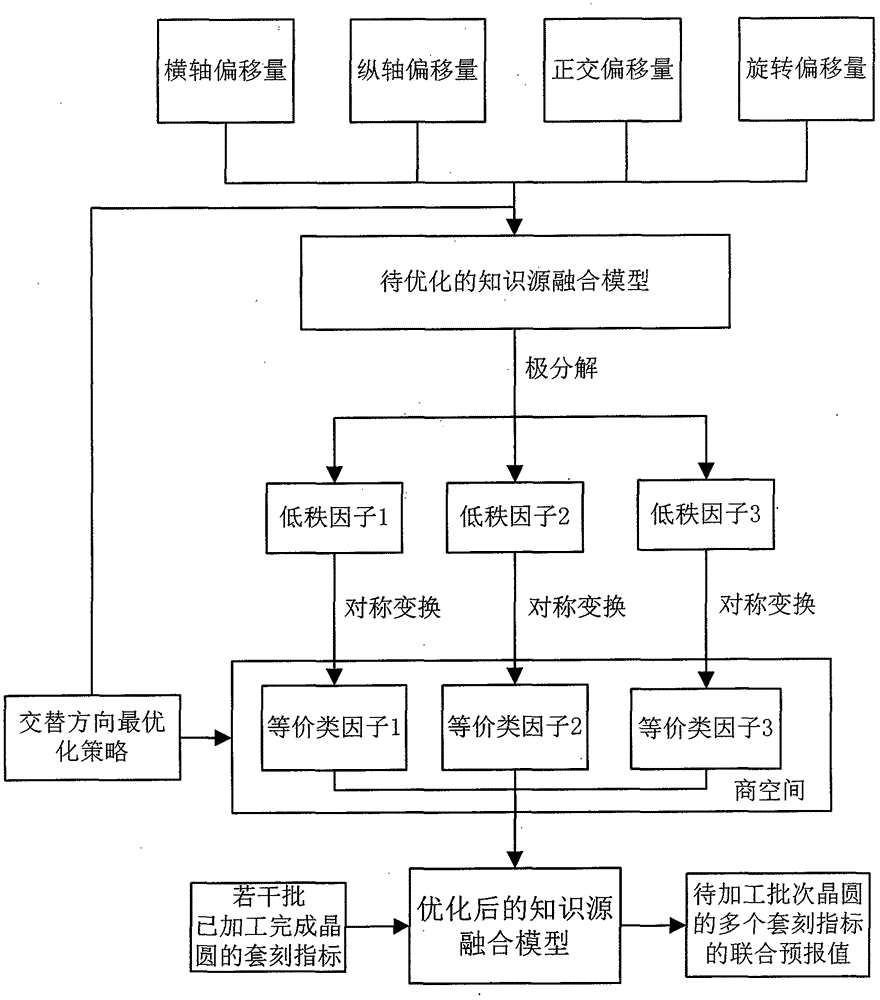

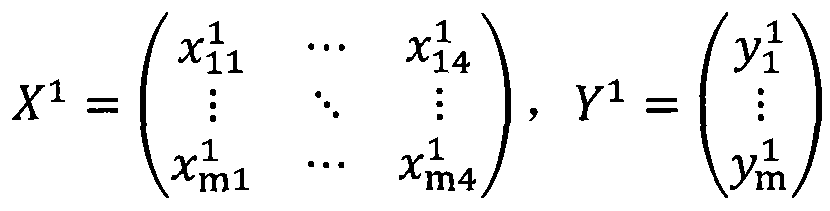

[0074] Step (1): Read the latest month's wafer-related data from the MES system database, where the fields include processing equipment, processing varieties, processing levels, processing time, and measurement indicators. Store these data in the training data table in the database server, and the corresponding sample inputs are X 1 , X 2 , X 3 , X 4 , the corresponding output is Y 1 , Y 2 , Y 2 , Y 4 , where each index input has a total of 4-dimensional features, that is, the first 4 batches of historical overlay measurement index...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com