Low-voltage power cable capable of temperature self-testing and fabrication method thereof

A technology of low-voltage power and manufacturing methods, which is used in cable/conductor manufacturing, power cables with shielding/conducting layers, insulated cables, etc., can solve the problems of cable line protection, tripping, power failure, insulation breakdown, etc., and achieve stable cable performance. 、Prevent line failure and ensure the effect of production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

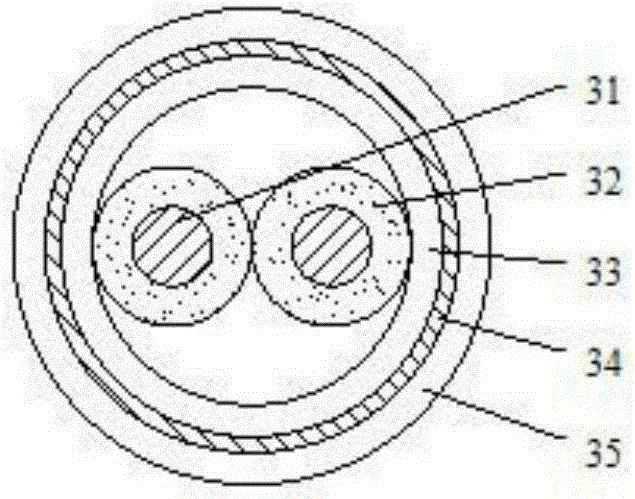

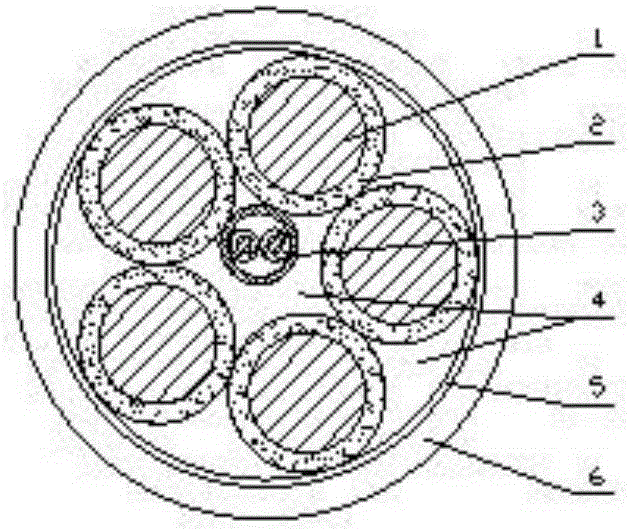

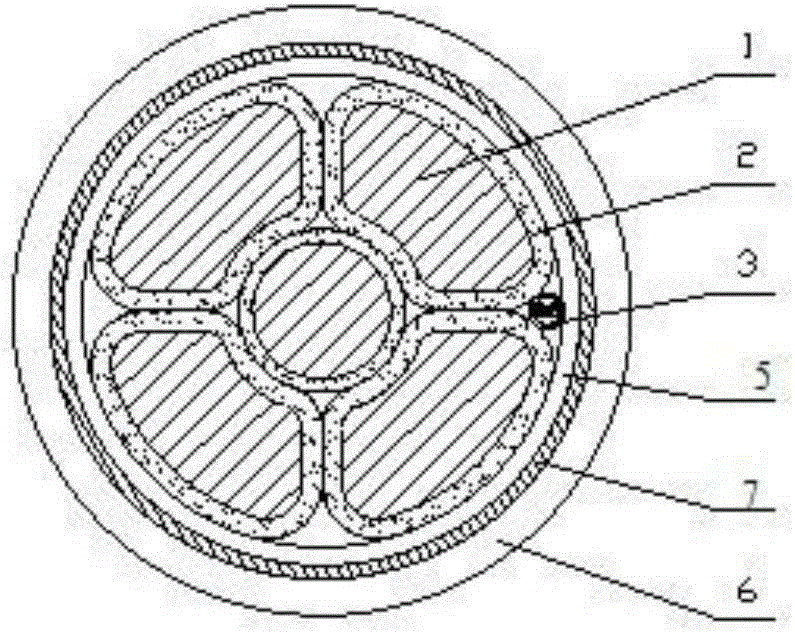

[0035] A self-measuring low-voltage power cable, including a number of insulated wire cores arranged in an outer sheath 6, each insulated wire core is composed of a conductor 1 and a core insulation sheath 2 covering the conductor 1, and a measuring wire is arranged in the outer sheath 6 Wen component 3, such as figure 1 As shown, the temperature measuring assembly 3 includes a temperature measuring wire, and outside the temperature measuring wire is a polyester liner 33, a shielding layer 34 and a plastic wrapping tape 35, and the temperature measuring wire consists of two copper core insulating sleeves 32. The copper core 31 is twisted in pairs, wherein the temperature measuring component 3 is arranged outside the wire core insulating sleeve 2, and is consistent with the length of the wire core insulating sleeve 2.

[0036] Among them, the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com