Low-leakage-current winding type solid electrolytic capacitor and production method thereof

A technology of solid electrolysis and production method, which is applied in the direction of solid electrolytic capacitors, etc., and can solve problems such as prolonging the production cycle, reducing leakage current, and long impregnation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

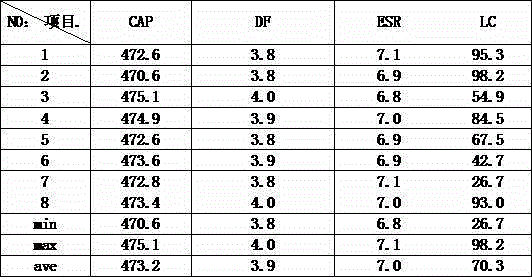

Embodiment 1

[0023] A kind of production method of winding type solid electrolytic capacitor with low leakage current, it comprises the following steps:

[0024] ⑴ Element preparation: The anode foil riveted with a positive guide pin and the cathode foil riveted with a negative guide pin are wound into a core with electrolytic paper sandwiched between them. The core is formed, carbonized, impregnated with a pretreatment agent, impregnated with a monomer, Impregnated with oxidant and polymerized at high temperature to produce prime;

[0025] The positive guide pin and the negative guide pin are guide pins after formation; the anode foil is formed foil with 1.8 times to 2.0 times the rated voltage of the capacitor, and its surface impurities are Cu 2+ 、Cu + , Fe 3+ , Cl - The sum of the ions is less than 10ppm; the cathode foil is carbon-coated foil, and the thickness of the carbon layer is 45nm; the anode foil and the cathode foil are cut and polished, and the burrs are not greater than ...

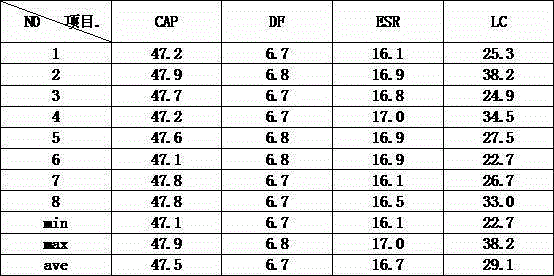

Embodiment 2

[0050] This embodiment further illustrates the present invention by taking the preparation of a wound-type solid electrolytic capacitor with a specification of 25V47μF as an example.

[0051] During the formation, since the rated voltage of the anode foil in this embodiment is ≥ 25V, the formation is carried out in divided voltage stages. The rated voltage from 25V to the rated withstand voltage of the anode foil (1.88 times the rated voltage of the capacitor) is divided into 4 sections, that is, 25V, 32V, 39V, 47V, and each section is 10min.

[0052] When aging, since the rated voltage of the capacitor is greater than 20V, the aging treatment should be performed at each stage of 20V, 24V, 27V, and 30V for 30 minutes.

[0053] As shown in Table 2, the specification prepared in this example is a 25V47μF winding solid electrolytic capacitor, its capacitance (CAP) is 47.1μF-47.9μF, loss (DF) 6.7-6.8, equivalent series resistance (ESR) 16.1 From mΩ to 17.0mΩ, the characteristics ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com