Tool setting device for atmospheric plasma jet machining

A technology of plasma and tool setting device, which is used in plasma welding equipment, metal processing equipment, manufacturing tools, etc. to achieve good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

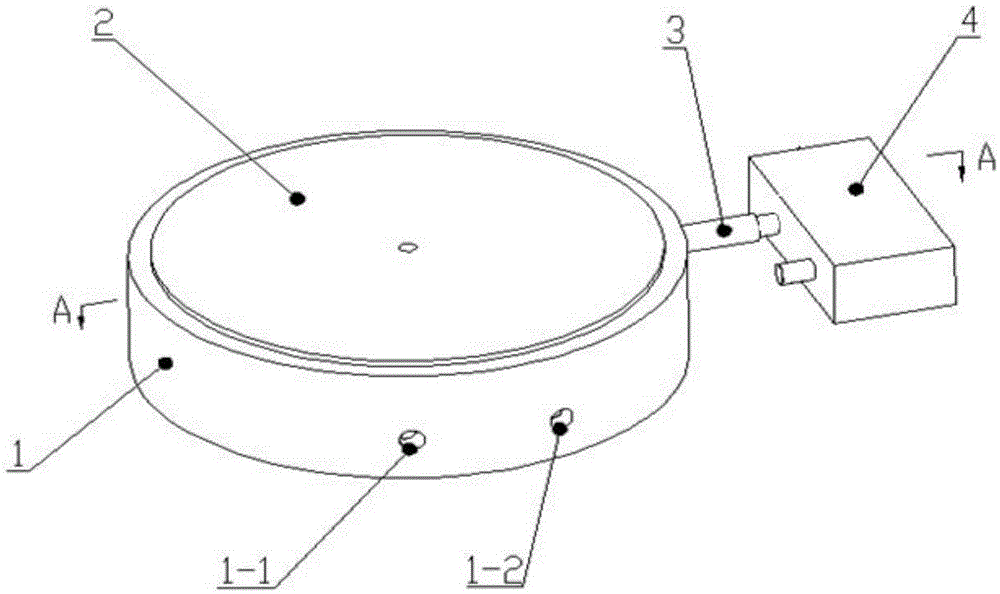

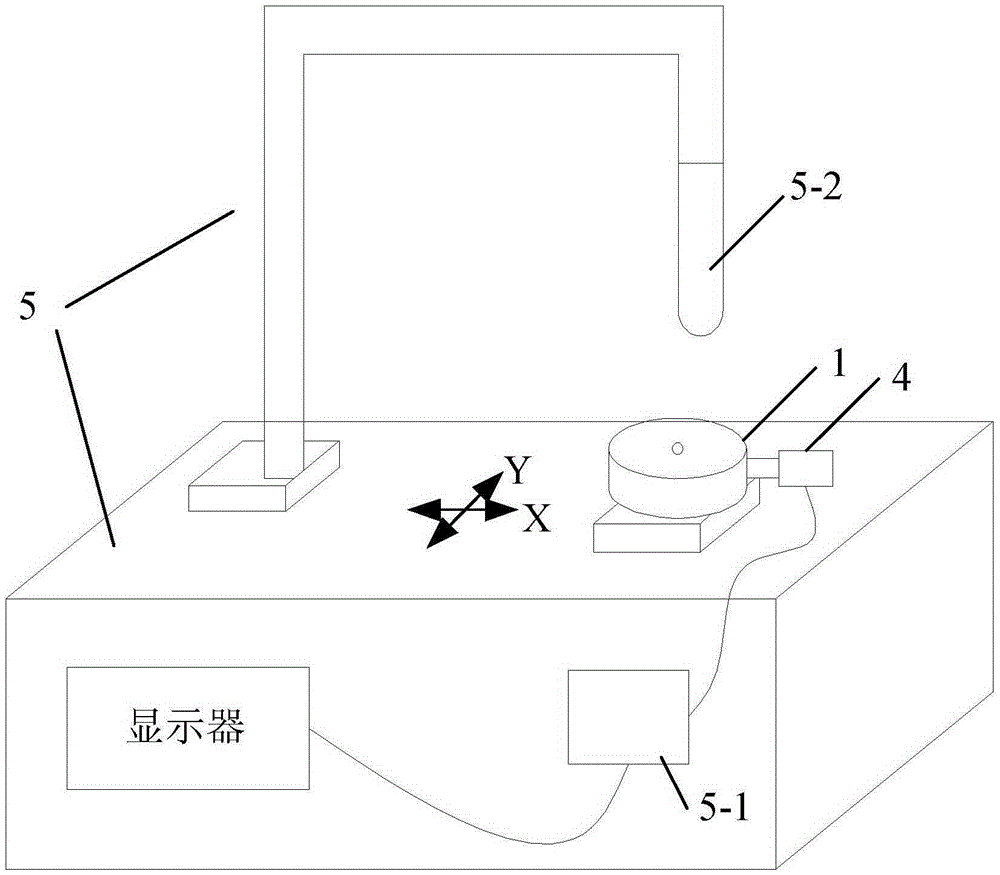

[0028] Specific implementation mode 1, refer to Figure 1 to Figure 6 Describe this embodiment in detail, a kind of atmospheric plasma jet machining tool setting device described in this embodiment, it comprises machine tool 5, and machine tool 5 comprises machine tool control system 5-1 and plasma jet emission device 5-2; Machine tool control system 5-1 is used to record the movement distance of the workbench of the machine tool 5; the plasma jet emission device 5-2 is located above the workbench of the machine tool 5;

[0029] It also includes a base 1, a fused silica piece 2, a connecting pipe 3 and a pressure sensor 4;

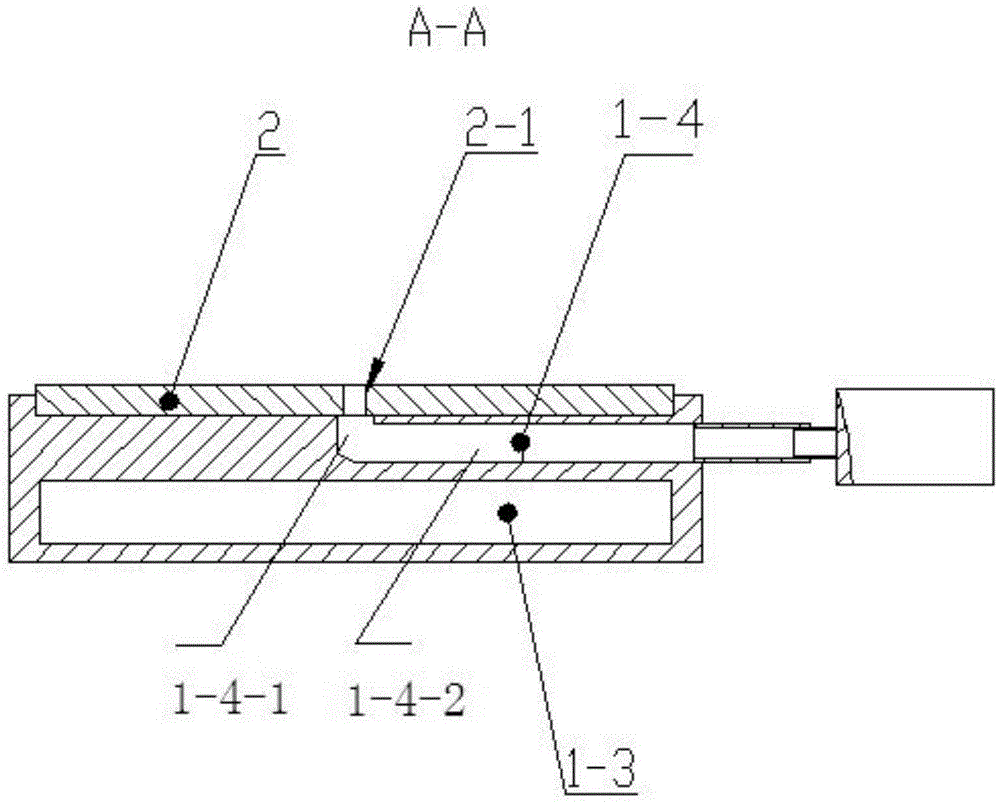

[0030] The upper surface of the base 1 is provided with a groove, the fused silica sheet 2 is fixedly arranged in the groove of the base 1, and the center of the fused silica sheet 2 is provided with a through hole 2-1;

[0031] The upper surface of the base 1 is provided with a channel 1-4, and the channel 1-4 includes a vertical channel 1-4-1 and a hori...

specific Embodiment approach 2

[0037] Specific Embodiment 2. This embodiment is a further description of the tool setting device for atmospheric plasma jet processing described in Embodiment 1. In this embodiment, a cooling cavity 1-3 is provided in the base 1 and is located in the channel Below the base 1-4; the outer surface of the base 1 is provided with a water inlet 1-1 and a water outlet 1-2 connected with the cooling chamber 1-3; the cooling chamber 1-3 is used to feed cold water to cool the fused silica sheet 2;

[0038] The water inlet 1-1 and the water outlet 1-2 are used to allow cold water to enter and exit from the cooling chamber 1-3.

[0039] In this embodiment, due to the high temperature of part of the atmospheric plasma jet, the fused silica sheet 2 will be melted and deformed without cooling. Therefore, water cooling is required to work under the high-temperature plasma jet with a temperature range of 800°C to 3000°C. The cold water enters the cooling cavity 1-3 from the water inlet 1-1, an...

specific Embodiment approach 3

[0041] Specific Embodiment 3. This embodiment is a further description of the tool setting device for atmospheric plasma jet processing described in Embodiment 2. In this embodiment, the diameter of the through hole 2 - 1 is 0.5mm-2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com