Optical fiber producing coating central concentrated feeding system

A material feeding system and coating technology, applied in the field of central centralized feeding system for optical fiber production and coating, can solve the problems of increasing production cost, coating loss, affecting production, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

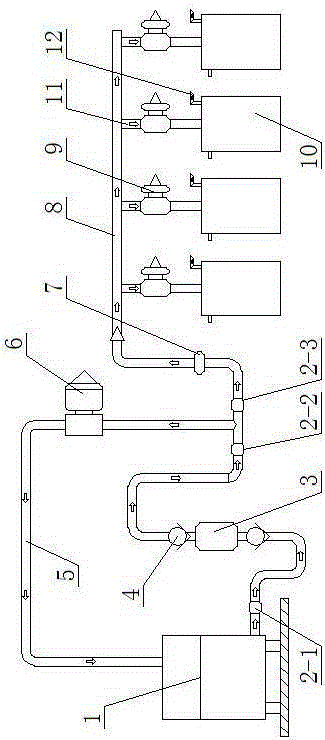

[0018] The optical fiber production and coating central centralized feeding system consists of raw material barrel 1, paint bubble detector a2-1, paint bubble detector b2-2, paint bubble detector c2-3, booster pump 3, one-way valve 4, The paint return pipeline 5, the return valve 6, the main pipeline 8, the pressure pump 9, the small material tank 10 and the drawing wire coating pipeline 12 are constituted. The capacity of the raw material barrel 1 is 1000 kg / barrel; The main pipe 8 is installed in the lower part, and the paint bubble detector a2-1, the booster pump 3, the paint bubble detector b2-2, the paint bubble detector c2-3, the pressure detector are installed on the main pipe 8 in order from left to right. 7 and the sub-pipeline 11, the two ends of the booster pump 3 are equipped with a check valve 4; the upper part of the raw material barrel 1 is equipped with a paint return pipeline 5, and the paint return pipeline 5 is equipped with a return valve 6, and the paint re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com