Method used for reductive amination using jet reactor

A jet reactor and reactor technology, which are applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of low conversion rate and high energy consumption of reductive amination, so as to improve production capacity and improve mixing efficiency. , the effect of suppressing side effects

Inactive Publication Date: 2016-01-13

CHINA PETROLEUM & CHEM CORP +1

View PDF8 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The purpose of the present invention is to provide a device and process method for liquid-phase hydrogenation reductive amination using a jet reactor to solve the problems of high energy consumption and low conversion rate during reductive amination in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

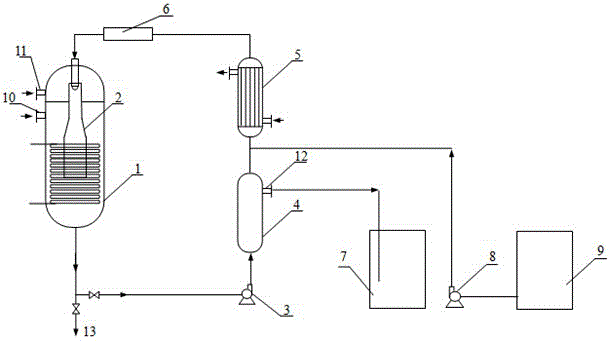

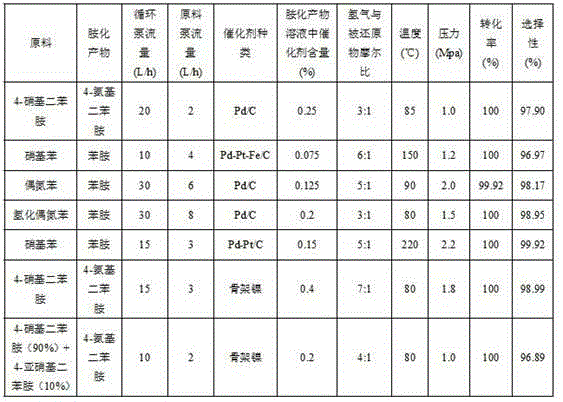

[0036] like figure 1 The reaction is carried out in the jet reactor shown for liquid-phase hydrogenation reductive amination, and the specific implementation parameters and results are shown in the table below.

[0037]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method used for reductive amination using a jet reactor, and belongs to the field of chemical technology. According to the method, the jet reactor is adopted. The jet reactor comprises a reactor, an ejector, a circulating pump, a concentration device, a heat exchanger, and a mixer. The jet reactor is used for chemical product hydrogenation reduction. According to the method, a mixture containing a catalyst, raw materials, and a target amination product is taken as a dynamic fluid, high speed liquid flow is obtained via injection, and stable turbulent flow is formed at a nozzle, and in addition, negative pressure is formed around the nozzle, entrainment of hydrogen is realized, and gas-liquid-solid complete mixing reaction is realized. After reaction, and obtained product is subjected to condensation separation so as to obtain partially aminated products; a concentrate containing the catalyst and a reduced material are subjected to preheating using the heat exchanger, and mixing using the mixer, and then are delivered into the ejector for circular reaction. The method can be used for obtaining amines via reduction of nitro compounds, nitroso compounds, azo-compounds, azoxy compounds, and hydride azo compound.

Description

technical field [0001] The invention relates to a liquid-phase hydrogenation reductive amination equipment and a process method, belonging to the technical field of chemical process and equipment. Background technique [0002] Amine compounds are important organic chemical raw materials and chemical products, such as: aniline, 4-aminodiphenylamine, etc. There are more than 300 kinds of chemical products and intermediates prepared from them, which are used in dyes, medicines, pesticides, explosives, spices, Rubber vulcanization accelerators are widely used in industries such as rubber vulcanization accelerators, and the development and utilization prospects are very broad. [0003] The catalytic hydrogenation method can make the reaction proceed in a directional manner, with few side reactions, good product quality and high yield, so it is the development direction of amine production. Compounds can be reduced by hydrogenation. At present, the methods for realizing reductiv...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C211/55C07C211/46C07C209/36C07C209/38C07C209/42

Inventor 金汉强杨忠林孙盛凯李玉杰丁红霞

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com