Preparation method of N,N-dimethyl-octan and decan or octan/decan amide, and special device therefore

A special device, dimethyl technology, applied to N, can solve the problems of low gas-liquid-solid three-phase contact efficiency, long reaction time, high energy consumption, etc., achieve high conversion rate and selectivity of reactants, improve selectivity, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

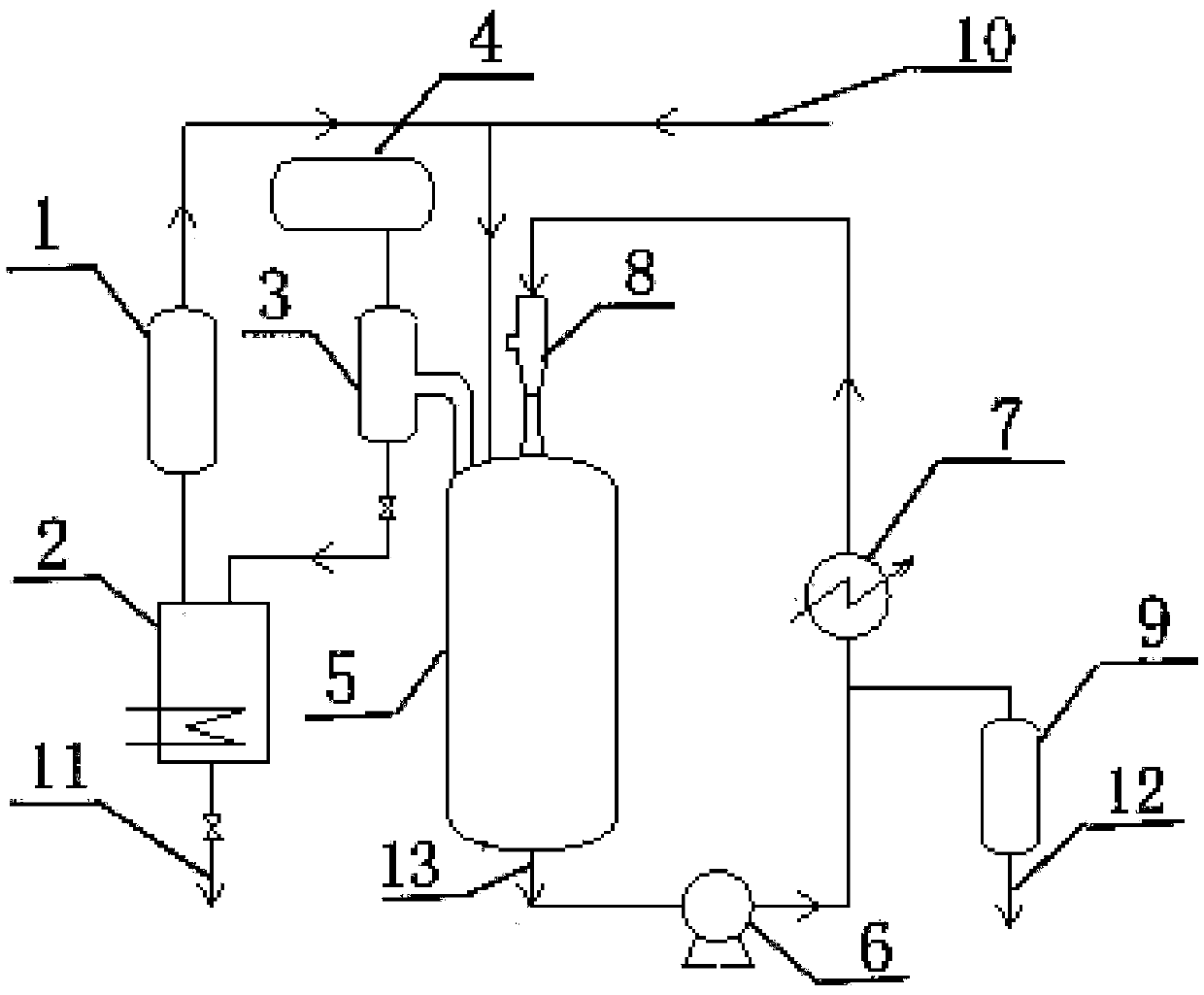

Method used

Image

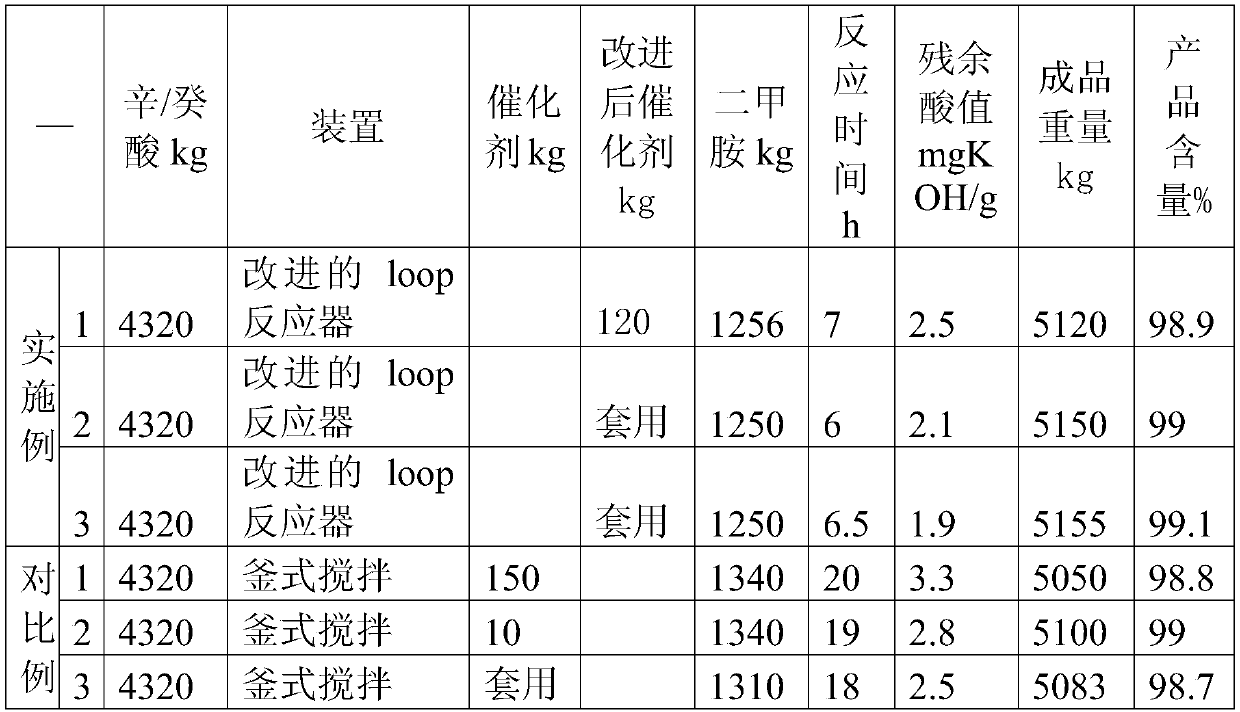

Examples

Embodiment

[0030] N, the preparation method of N-dimethyl-octane / capric amide comprises the following steps:

[0031] 1) After mixing 150Kg catalyst and 4320Kg caprylic / capric acid evenly, add them into the reactor, replace with nitrogen at least three times, so that the material can be sprayed circularly in the reactor; the circular spray flow rate is 100-200m 3 / h;

[0032] 2) Control the temperature in the reactor to 20-300°C, and keep the material circulating and spraying in the reactor; pass the metered dimethylamine into the reactor, and control the pressure in the reactor to 0.05-0.5MPa; if the pressure is high, reduce Slowly feed the speed of dimethylamine;

[0033] 3) After the water-containing material in the reaction is vaporized and condensed, the generated water is separated through the oil-water separator; the separated water is analyzed by amine to resolve the dimethylamine therein, and is recovered for mechanical use;

[0034] 4) After passing through dimethylamine, kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com