Novel waterproof rolled material for tunnel

A technology for waterproofing membranes and tunnels, applied in tunnels, tunnel linings, wellbore linings, etc., can solve the problems of increased production costs, waste of materials, time-consuming and labor-intensive, etc., and achieves cost-saving, low-cost, and firm connection effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

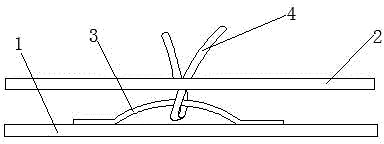

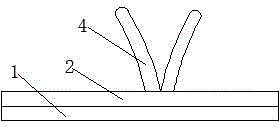

[0017] A new type of waterproof membrane for tunnels, including polyester non-woven fabric, polyethylene impermeable film, and suspenders. Non-woven fabric, polyethylene impermeable film and polyester non-woven fabric are connected into one body through ultrasonic welding with a strength greater than 15MPa.

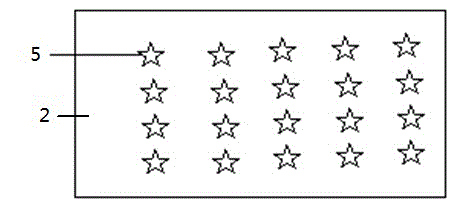

[0018] There are ultrasonic welding solder joints on the waterproof membrane, and the solder joints on the polyethylene impermeable membrane are arranged in a regular geometric arrangement in a dot matrix. The solder joints are star-shaped, quadrilateral, and elliptical. The middle part of the waterproofing membrane.

[0019] There is a hot-melt adhesive layer between the polyethylene impermeable film and the polyester non-woven fabric. The distance between the solder points of two adjacent rows is 15-35mm, and the distance between the solder points of two adjacent rows is 15- 25mm. The thickness of the polyester non-woven fabric is 0.15-0.35cm, and the thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com