Device for dry food forming

A food forming and drying technology, applied in the field of food machinery, can solve the problems of inability to form a group, damaged dough, scattered in Sichuan, etc., and achieve the effect of small interaction force and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

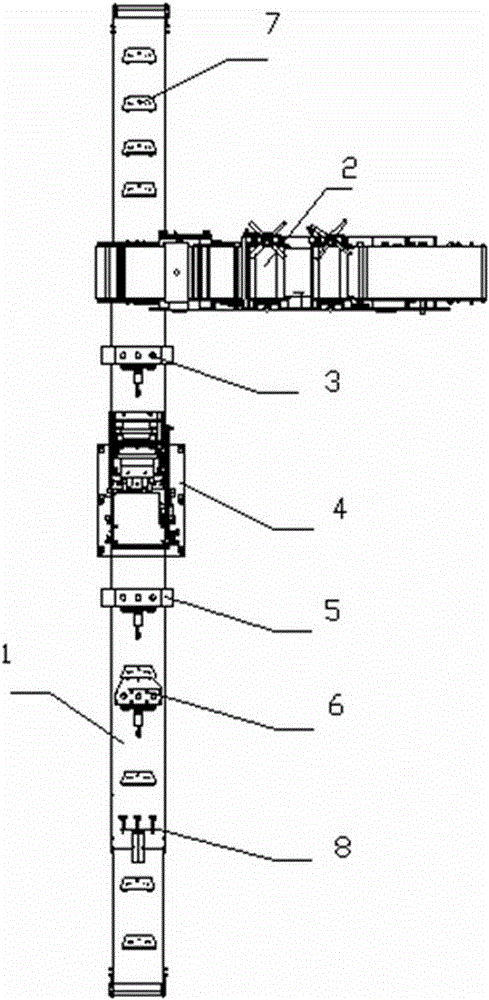

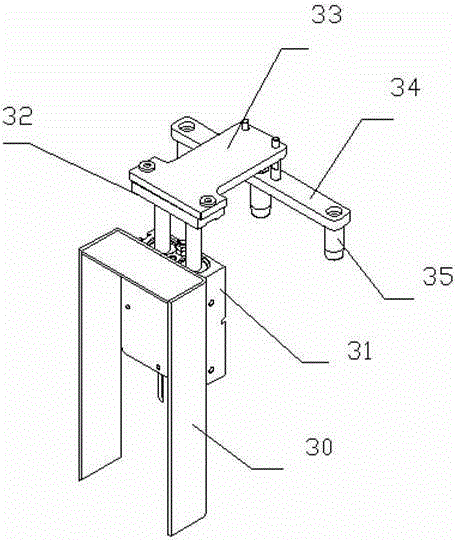

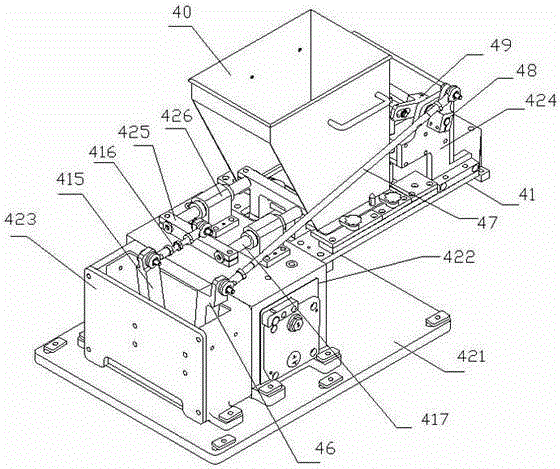

[0062] This embodiment discloses a device for forming dry food, which includes a conveyor 1, a dough forming mechanism 2, a peeling mechanism 3, a filling mechanism 4, a filling mechanism 5 and a forming mold 7, the forming mold 7 Fixed on the conveyor 1, the dough forming mechanism 2, piercing mechanism 3, filling mechanism 4 and stuffing mechanism 5 are sequentially arranged above the conveyor, and according to the conveying direction of the conveying mechanism, the dough forming mechanism 2 is located at the In front of the mechanism 3, the piercing skin mechanism 3 is located in front of the stuffing mechanism 4, and the stuffing mechanism 4 is positioned in the front of the stuffing mechanism 5.

[0063] The conveyor includes an endless conveyor belt, a driving roller, a driven roller and a driving motor, the endless conveyor belt is covered on the driving roller and the driven roller, the driving motor is connected with the driving roller through a belt, and the molding d...

Embodiment 2

[0084] This embodiment discloses a device for forming dry food, including a conveyor 1, a dough forming mechanism 2, a peeling mechanism 3, a filling mechanism 4, a filling mechanism 5, a shaping mechanism 6 and a forming mold 7. The forming mold 7 is fixed on the conveyor 1, and the dough forming mechanism 2, the skin mechanism 3, the stuffing mechanism 4, the stuffing mechanism 5 and the shaping mechanism are successively arranged above the conveyor, according to the conveying direction of the conveyor mechanism, The dough forming mechanism 2 is positioned at the front of the skin mechanism 3, the skin mechanism 3 is positioned at the front of the stuffing mechanism 4, the stuffing mechanism 4 is positioned at the front of the stuffing mechanism 5, and the shaping mechanism is positioned at the rear of the stuffing mechanism.

[0085] The conveyor includes an endless conveyor belt, a driving roller, a driven roller and a driving motor, the endless conveyor belt is covered on ...

Embodiment 3

[0108]This embodiment discloses a device for forming dry food, including a conveyor 1, a dough forming mechanism 2, a peeling mechanism 3, a filling mechanism 4, a filling mechanism 5, a shaping mechanism 6, a forming mold 7 and a pushing mechanism. The material mechanism 8, the forming mold 7 is fixed on the conveyor 1, the dough forming mechanism 2, the piercing mechanism 3, the filling mechanism 4, the stuffing mechanism 5 and the shaping mechanism are successively arranged on the top of the conveyor, according to the conveying The conveying direction of the mechanism, the dough forming mechanism 2 is located in front of the piercing mechanism 3, the skin piercing mechanism 3 is located in front of the stuffing mechanism 4, the stuffing mechanism 4 is located in front of the stuffing mechanism 5, the shaping mechanism 6 is located in the rear of the stuffing mechanism 5, and the material is pushed Mechanism is positioned at shaping mechanism 6 rears.

[0109] The conveyor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com