Preparation method of high-strength electroceramic

A high-strength, electric porcelain technology, applied to clay products, other household utensils, household utensils, etc., can solve the problem of single reinforcement of corundum particles, and achieve the effect of improving the strengthening and toughening effect, high strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

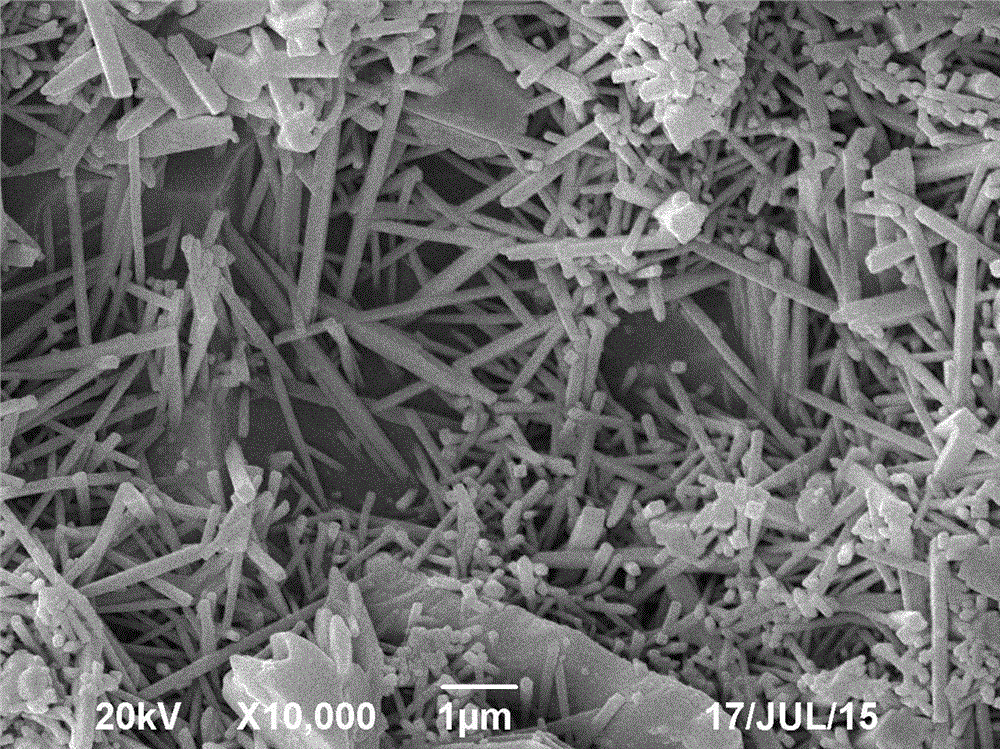

Image

Examples

Embodiment 1

[0030] Example 1 : A method for preparing high-strength electric porcelain synergistically reinforced by mullite whiskers and corundum particles, specifically:

[0031] (1) Mix calcined bauxite, mullite, high plastic clay and feldspar according to the following parts by mass:

[0032] Calcined bauxite: 25 parts;

[0033] Mullite: 30 parts;

[0034] High plastic clay: 30 parts;

[0035] Feldspar: 15 parts;

[0036] Among them, calcined bauxite, mullite and feldspar are all powders with an average particle size of less than 10 microns;

[0037] (2) After mixing the raw materials, add water with the same total mass as the solid raw materials, and ball mill for 3 hours to obtain a slurry;

[0038] (3) Sieve the slurry, remove iron, and obtain mud cake after dehydration by pressure filtration;

[0039] (4) The mud cake is roughed and stale for more than 24 hours, and then extruded with a vacuum mud mixer under the condition of an absolute pressure of 4kPa to obtain an electr...

Embodiment 2

[0042] Example 2 : A method for preparing high-strength electric porcelain synergistically reinforced by mullite whiskers and corundum particles, specifically:

[0043] (1) Mix calcined bauxite, mullite, high plastic clay and feldspar according to the following parts by mass:

[0044] Calcined bauxite: 30 parts;

[0045] Mullite: 30 parts;

[0046] High plastic clay: 20 parts;

[0047] Feldspar: 20 parts;

[0048] Among them, calcined bauxite, mullite and feldspar are all powders with an average particle size of less than 10 microns;

[0049] (2) After mixing the raw materials, add water with the same total mass as the solid raw materials, and ball mill for 5 hours to obtain a slurry;

[0050] (3) Sieve the slurry, remove iron, and obtain mud cake after dehydration by pressure filtration;

[0051] (4) The mud cake is aged for more than 24 hours after being roughed, and then extruded into a wet electric ceramic billet of the required size with a vacuum mud mixer under th...

Embodiment 3

[0054] Example 3 : A method for preparing high-strength electric porcelain synergistically reinforced by mullite whiskers and corundum particles, specifically:

[0055] (1) Mix calcined bauxite, mullite, high plastic clay and feldspar according to the following parts by mass:

[0056] Calcined bauxite: 20 parts;

[0057] Mullite: 20 parts;

[0058] High plastic clay: 35 parts;

[0059] Feldspar: 25 parts;

[0060] Among them, calcined bauxite, mullite and feldspar are all powders with an average particle size of less than 10 microns;

[0061] (2) After mixing the raw materials, add water with the same total mass as the solid raw materials, and ball mill for 4 hours to obtain a slurry;

[0062] (3) Sieve the slurry, remove iron, and obtain mud cake after dehydration by pressure filtration;

[0063] (4) The mud cake is aged for more than 24 hours after being roughed, and then extruded into a wet electric ceramic billet of the required size with a vacuum mud mill under the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com