Water-soluble solid silicon fertilizer and production method and preparation device thereof

A water-soluble silicon preparation device technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of large fertilization amount, low plant absorption rate, poor water solubility of silicon fertilizer, etc., achieve small fertilization amount, high content, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

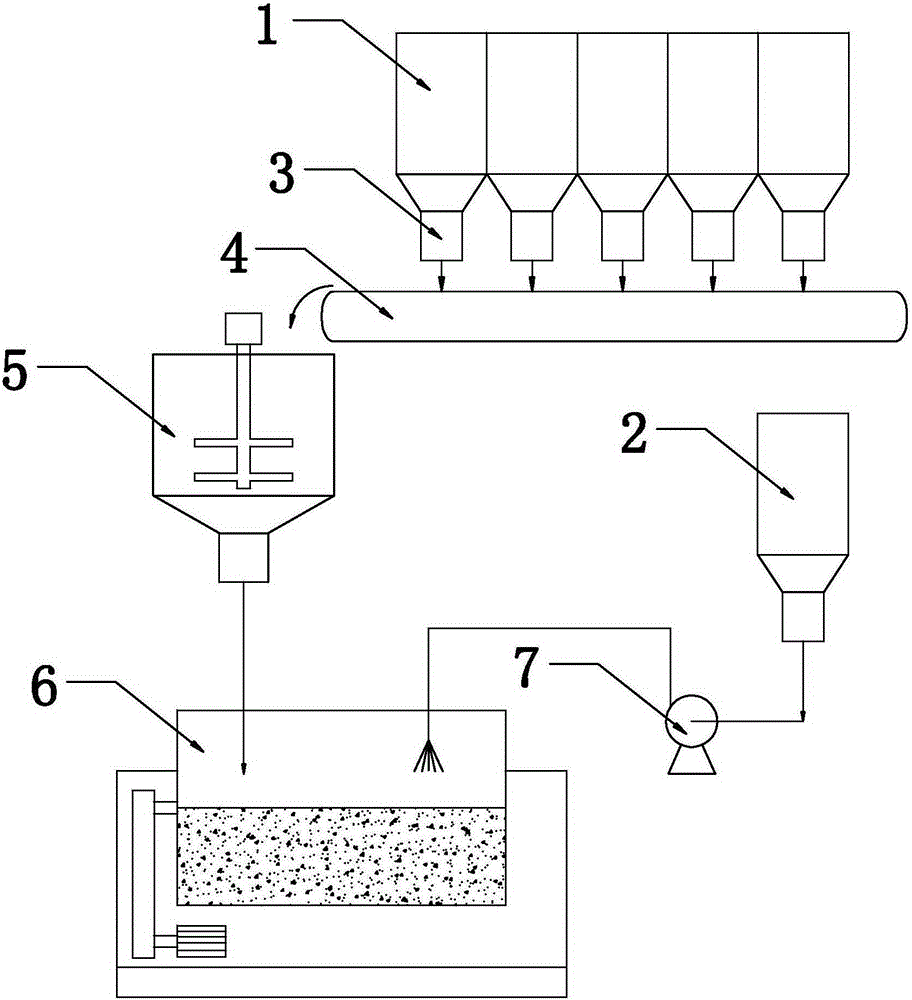

Image

Examples

Embodiment 1

[0023] A water-soluble silicon fertilizer, the water-soluble silicon fertilizer is made of the following raw materials in weight percentage: 52.5% powdered instant sodium silicate, 15% sodium humate, 15% urea, 7.5% magnesium sulfate, 9.85% liquid sodium silicate, 0.15% sodium carboxymethyl cellulose, of which the modulus of powdered instant sodium silicate is 2.85-3.0, the content of water-soluble silicon is 58-62% based on silicon dioxide, and the liquid silicon The modulus of sodium bicarbonate is 3.2-3.3, and the content of water-soluble silicon is 26-27% calculated by silicon dioxide.

Embodiment 2

[0025] A water-soluble silicon fertilizer, the water-soluble silicon fertilizer is made of the following raw materials in weight percentage: 53.9% powdered instant sodium silicate, 18% sodium humate, 18% urea, 5% magnesium sulfate, 5% liquid sodium silicate, 0.1% sodium carboxymethyl cellulose, the modulus of powdered instant sodium silicate is 2.85-3.0, the content of water-soluble silicon is 50-58% based on silicon dioxide, and the liquid silicon The modulus of sodium bicarbonate is 3.2-3.3, and the content of water-soluble silicon is 26-27% calculated by silicon dioxide.

Embodiment 3

[0027] A water-soluble silicon fertilizer, the water-soluble silicon fertilizer is made of the following raw materials in weight percentage: 56.8% powdered instant sodium silicate, 10% sodium humate, 13% urea, 10% magnesium sulfate, 10% liquid sodium silicate, 0.2% sodium carboxymethyl cellulose, of which the modulus of powdered instant sodium silicate is 2.85-3.0, the content of water-soluble silicon is 62-70% based on silicon dioxide, and the liquid silicon The modulus of sodium bicarbonate is 3.2-3.3, and the content of water-soluble silicon is 26-27% calculated by silicon dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com