a kind of ag 2 Non-fired densification preparation process of se bulk thermoelectric materials

A technology of thermoelectric material and preparation process, applied in the field of non-burning densification preparation process, can solve the problems of inevitable temperature field temperature gradient, non-uniform composition, limitation of thermoelectric materials, etc., so as to avoid a small amount of single time and excellent thermoelectric performance. , the effect of improving the thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] a kind of Ag 2 The non-fired densification preparation process of Se bulk thermoelectric materials, the specific steps are as follows:

[0027] 1) Using Ag powder and Se powder as raw materials, Ag powder and Se powder are weighed according to the molar ratio of 2:1, a total of 4 parts, each 6.5g, respectively numbered as A, B, C, D;

[0028] 2) Put each raw material in the agate mortar of SFM-8 agate bowl milling machine, pre-mix well with a medicine spoon, set the rotation speed of the mortar to 10rpm, and the rotation speed of the pestle to 30rpm, stop grinding after 20min to obtain a mixed powder body;

[0029] 3) Put the obtained mixed powder into a Φ20mm WC mold, and then place the mold on the YLG-60 electric tablet press of Hefei Kejing Material Technology Co., Ltd., and set the pressure of each test group to 6MPa, 8MPa, 10MPa, and 18MPa respectively (The actual pressure of the powder in the mold is 337.5MPa, 450MPa, 562.5MPa, 1GPa). After holding the pressure ...

Embodiment 2

[0032] a kind of Ag 2The densification preparation process of Se bulk thermoelectric materials (high-volume densification preparation process), the specific steps are as follows:

[0033] 1) Using Ag powder and Se powder as raw materials, Ag powder and Se powder are weighed in a molar ratio of 2:1, a total of 26g;

[0034] 2) Put it in the agate mortar of SFM-8 agate bowl milling machine, pre-mix it with a medicine spoon, the rotation speed of the mortar is 10rpm, the rotation speed of the pestle is set at 30rpm, and stop grinding after 20min;

[0035] 3) Put the mixed powder into a Φ20mm WC mold, then place the mold on the YLG-60 electric tablet press of Hefei Kejing Material Technology Co., Ltd., and set the pressure to 18MPa (corresponding to the actual pressure of the powder in the mold is 1GPa) , release the pressure after maintaining the pressure for 10 minutes, and take out the obtained block after demoulding.

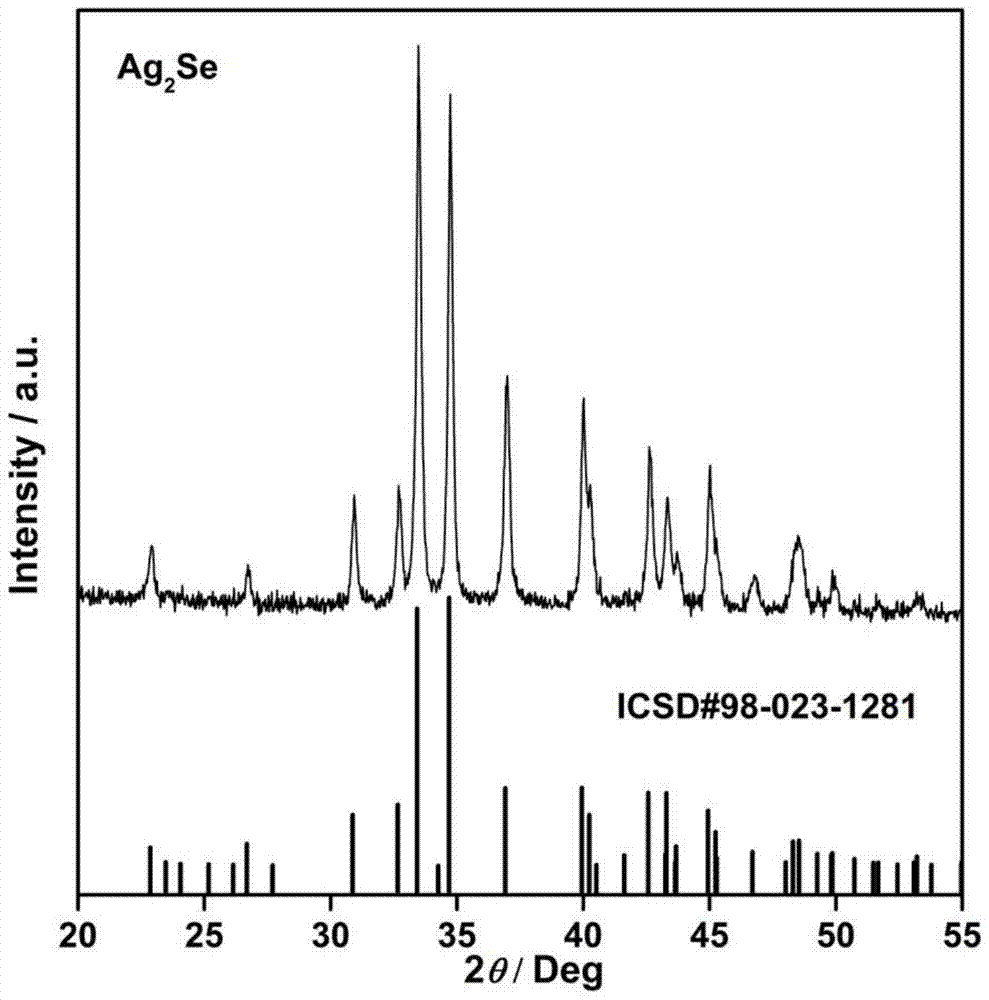

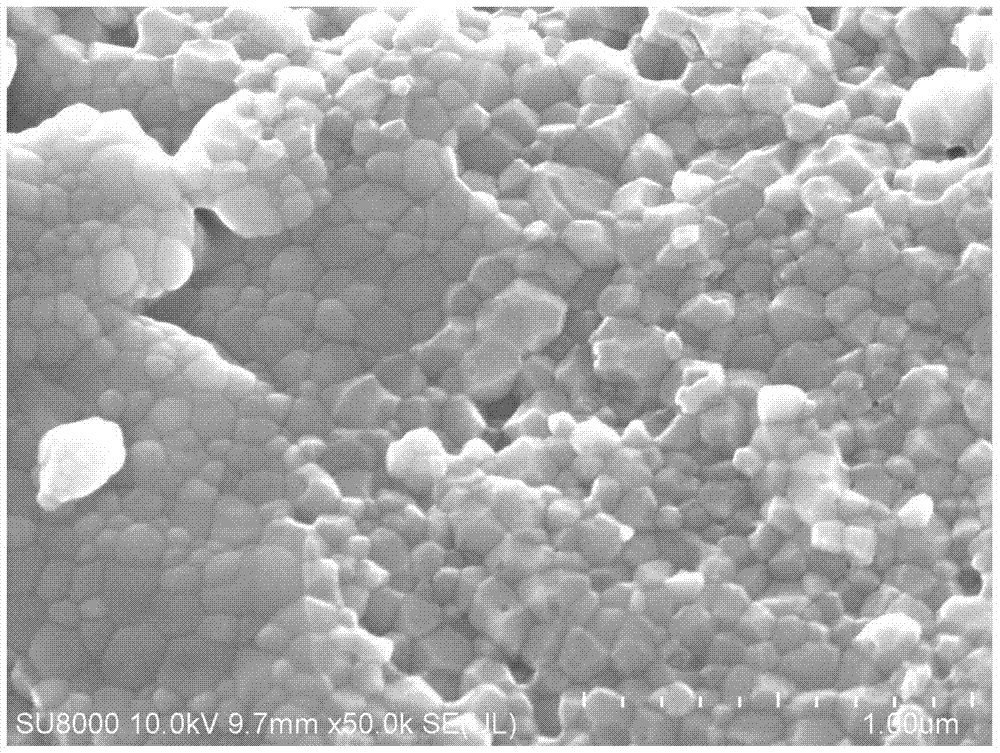

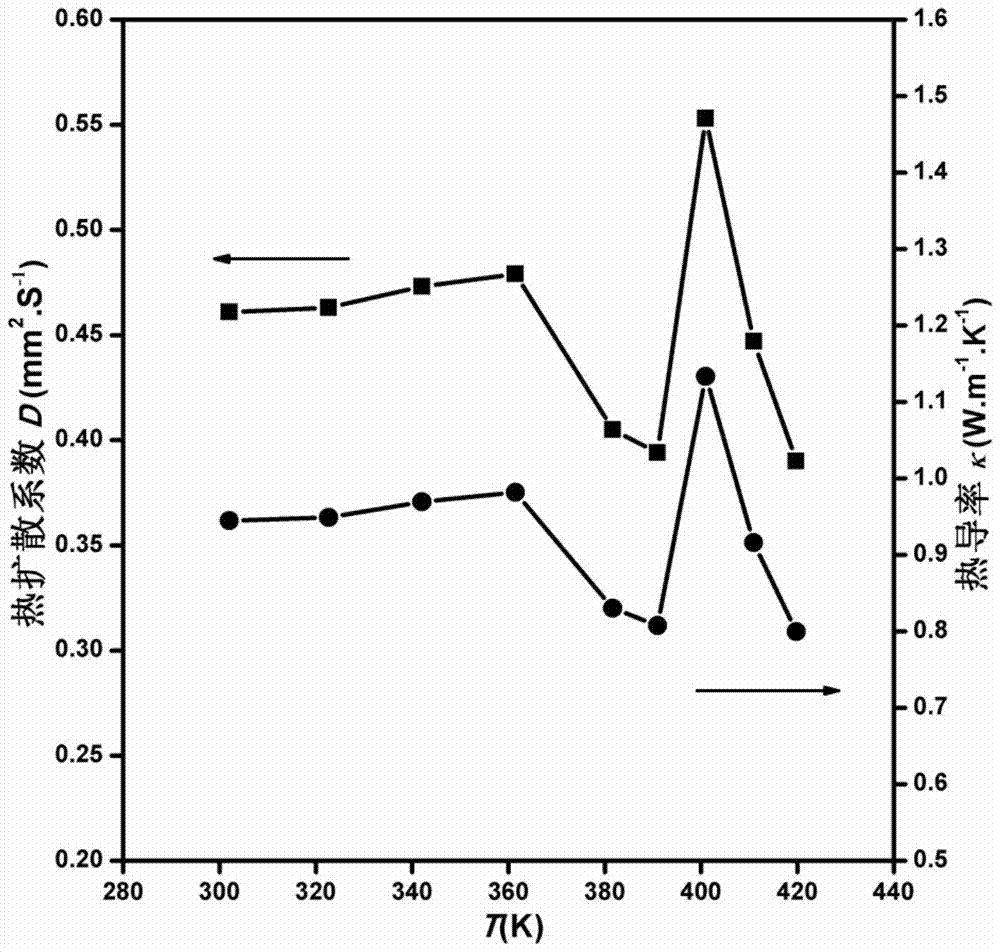

[0036] Carry out X-ray diffraction analysis to the produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com