A preparation method of modified electronic cigarette floc filler fiber

A technology for fillers and electronic cigarettes, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problem of no antibacterial property, adsorption/desorption performance needs to be improved, and fiber surface modification without flocculent fillers to enhance antibacterial properties and adsorption/desorption Desorption performance and other issues, to achieve good adsorption / desorption performance, simple and reliable preparation method, not easy to breed bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for making modified floc filler fibers for electronic cigarettes, comprising the following steps:

[0028] Step 1) Wash the flocs of the electronic cigarette three times with toluene and acetone respectively, and ultrasonically clean the flocs washed with the organic solvent with distilled water for 2 hours.

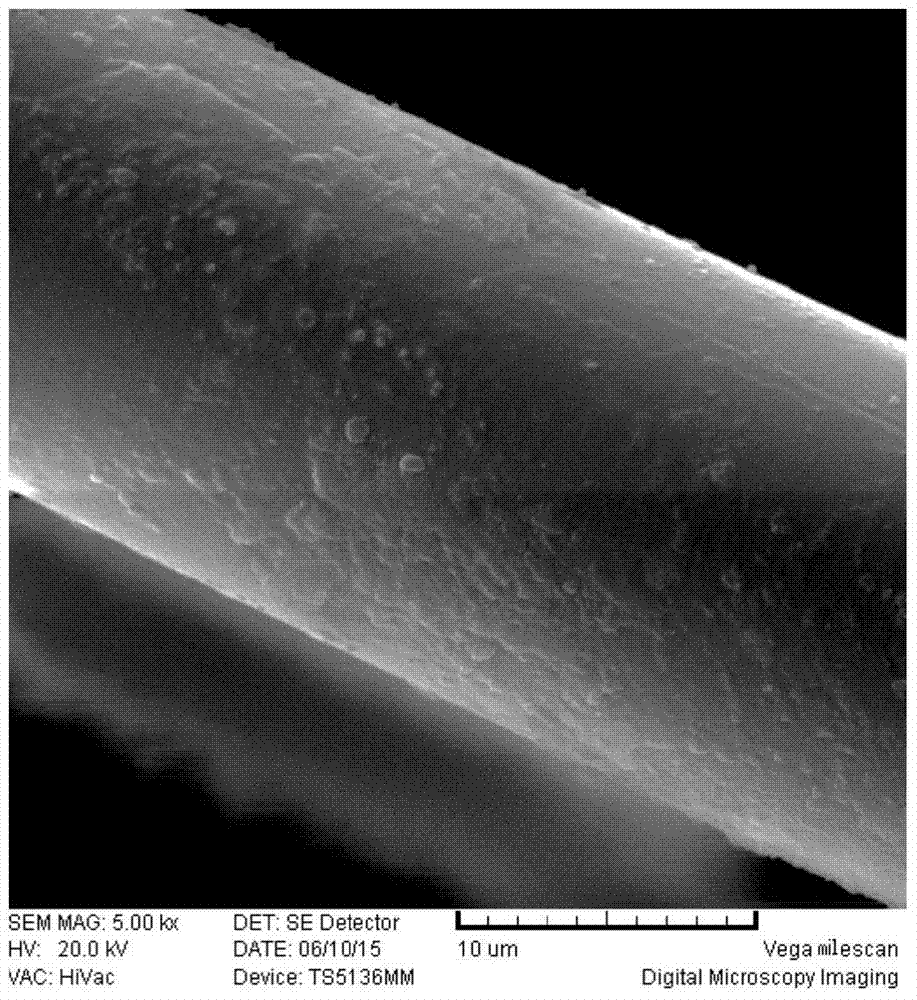

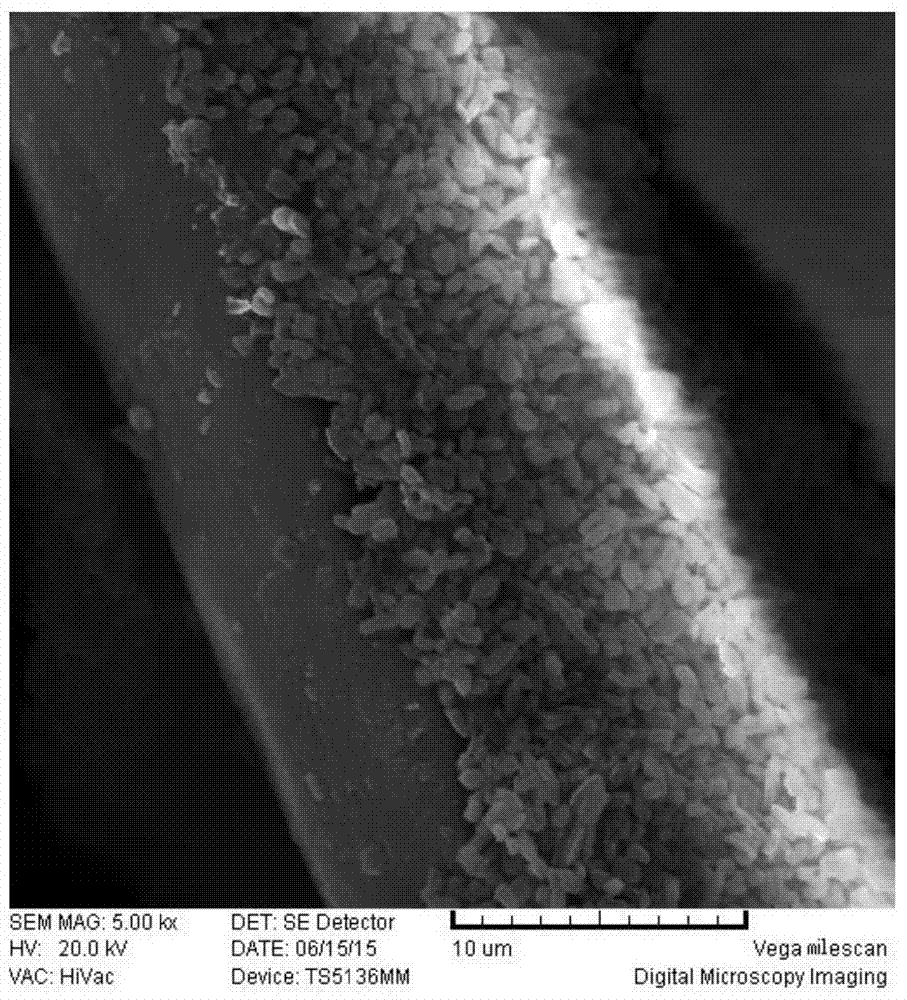

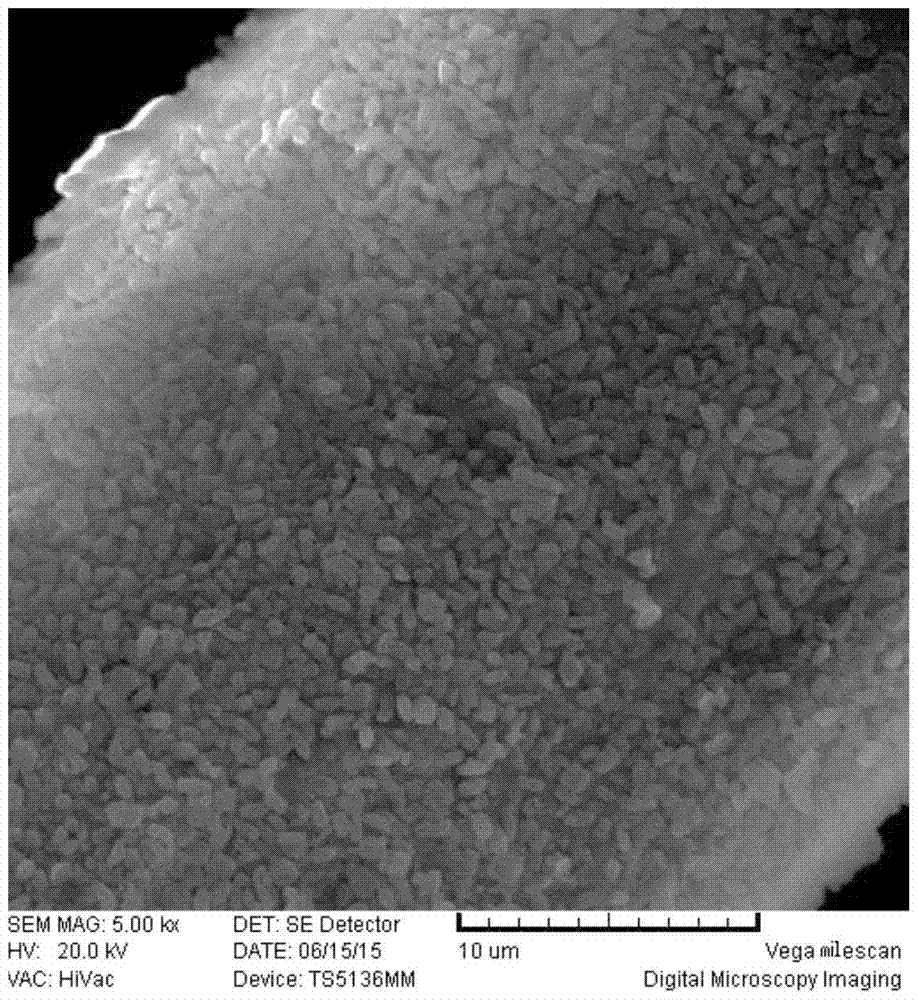

[0029] Step 2) Dissolving 4-(2-aminoethyl)-1,2-benzenediol in distilled water to a concentration of 1 mg / ml, and adjusting the pH of the solution to 7 with tris. Weigh 0.1 g of the washed electronic cigarette flocculent filler fiber and add it to 20ml of prepared 4-(2-aminoethyl)-1,2-benzenediol solution, react at room temperature for 24 hours, and dissolve the obtained flocculent The material was washed with distilled water and dried to obtain electronic cigarette floc filler fibers (such as figure 1 shown).

[0030] Step 3) Add the electronic cigarette floc filler fiber to 20ml of toluene diisocyanate in toluene solution, the concentration of the solu...

Embodiment 2

[0033] A method for making modified floc filler fibers for electronic cigarettes, comprising the following steps:

[0034] Step 1) The electronic cigarette flocs were washed three times with ethyl acetate and ethanol respectively, and the electronic cigarette floc filler fibers washed with an organic solvent were ultrasonically cleaned with distilled water for 2 hours.

[0035] Step 2) Dissolving 3,4 dihydroxyphenylalanine in distilled water, the concentration of the solution is 5 mg / ml, and then adjusting the pH of the solution to 8.5 with tris. Weigh 0.1 g of the washed e-cigarette flocculent filler fiber and add it to 20ml of the prepared 3,4 dihydroxyphenylalanine solution, react at room temperature for 24 hours, and wash the obtained e-cigarette flocculent filler fiber with distilled water ,drying.

[0036] Step 3) Add the electronic cigarette floc filler fiber to 20ml of bisphenol A epoxy resin in toluene solution, the solution concentration is 10mg / ml, and react at roo...

Embodiment 3

[0039] A method for making modified floc filler fibers for electronic cigarettes, comprising the following steps:

[0040] Step 1) Wash the flocs of the electronic cigarette three times with ethanol and acetone respectively, and ultrasonically clean the flocs washed with organic solvents with distilled water for 2 hours.

[0041] Step 2) 3 mg of 4-amino-1,2-catechol and 2 mg of 3,4-dihydroxyphenylalanine were dissolved in 1000 ml of distilled water, and the pH of the solution was adjusted to 9 with Tris . Weigh 0.1 g of the washed electronic cigarette floc filler fiber and add it to 20 ml of the prepared mixed solution of 4-amino-1,2-catechol and 4-dihydroxyphenylalanine, and react at room temperature for 24 hours. The resulting flocs were washed with distilled water and dried.

[0042] Step 3) Add the flocculent filler fiber of the electronic cigarette to the toluene solution of 4,4'-biphenyl ether dicarboxylic anhydride, the concentration of the solution is 10 mg / ml, and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com