Novel formaldehyde-free low-damage crease-resistant finishing agent and finishing method thereof

An anti-wrinkle finishing agent and low-damage technology, applied in the field of formaldehyde-free low-damage anti-wrinkle finishing agent and its finishing field, can solve problems such as hard hand feel and fabric yellowing, and achieve low price, low usage, good market promotion benefits and economy. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

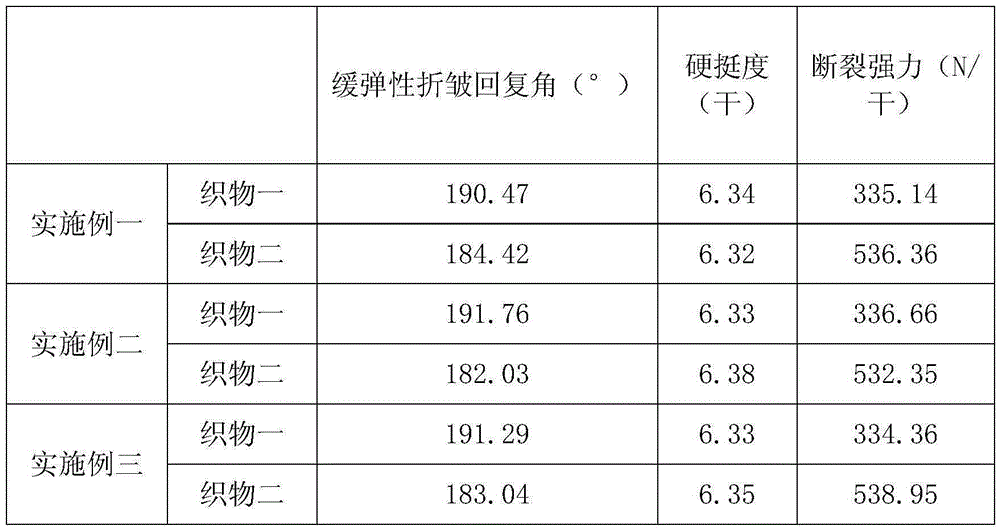

[0024] Embodiment: each component of the embodiment product of the present invention is shown in Table 1.

[0025] Table 1: Formaldehyde-free low-damage anti-wrinkle finishing agent composition (unit: parts by weight)

[0026]

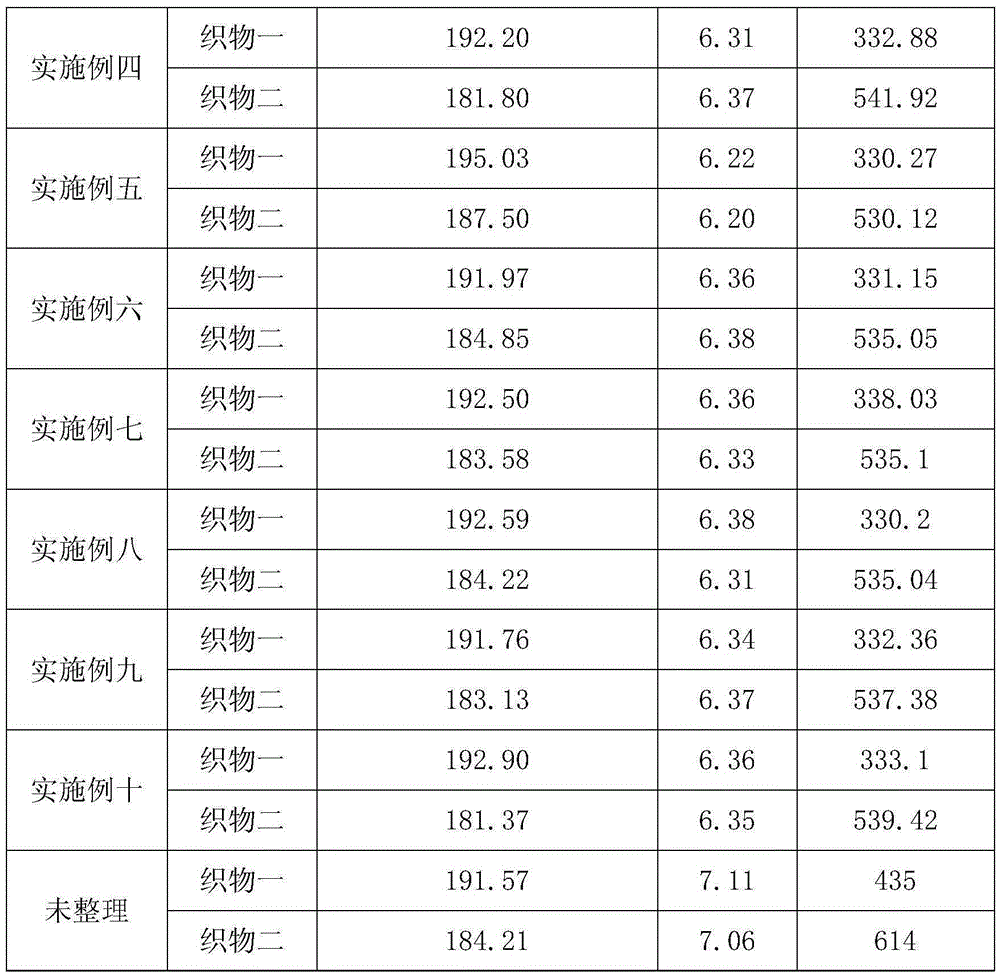

[0027] The finishing method of the fabric by the formaldehyde-free low-damage anti-wrinkle finishing agent of the present invention is to soak the fabric in a sodium citrate solution (0.5% in mass concentration) for 30 minutes at room temperature, take it out and drain it; The drying rate is 85%; drying at 90°C for 5 minutes; baking at 135°C for 2 minutes, followed by cold water washing and hot water washing respectively, followed by drying to complete the finishing process. The concentration of the finishing agent solution is 30-40g / L.

[0028] Fabric 1: linen fabric, five pieces of three-flying satin, the density is 340×340 threads / 10cm.

[0029] Fabric 2: linen / polyester interwoven fabric, five pieces of three-flying satin, the density is 340×3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com