Rheological evaluation method of polyethylene for medical instruments

A medical device and evaluation method technology, applied in the field of medicine and medical treatment, can solve the problems of unrepresentable characteristics, high operation requirements, long test cycle, etc., and achieve the effect of low sample uniformity requirements, fast method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

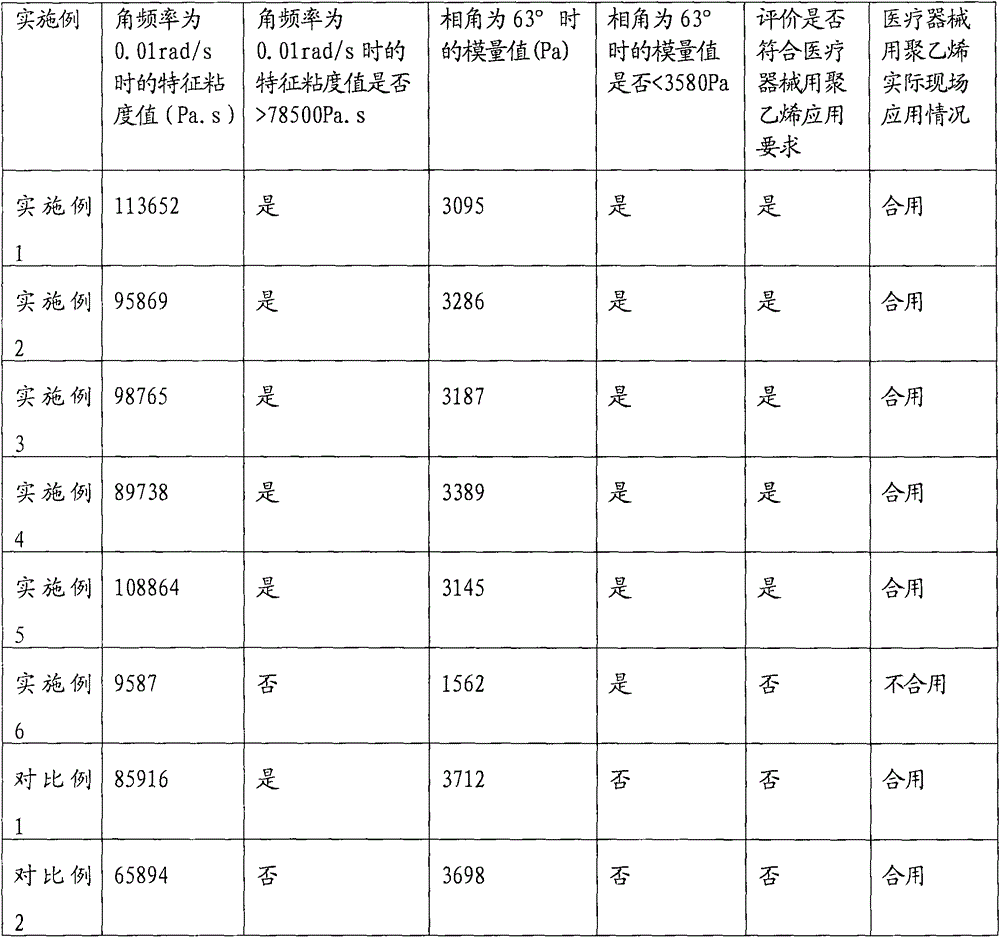

Embodiment 1

[0022] Place polyethylene pellets for medical devices on a hot press with a mold, melt at 200°C for 8.5 minutes, then apply a pressure of 3.5Mpa and continue hot pressing for 4 minutes, and press to obtain a uniform test sample for use; place the sample under strain The controlled rheometer has a diameter of 25mm on a cone-plate fixture with a cone angle of 5°. The torque accuracy of the rheometer is 0.1nNm. The temperature is set at 200°C, a strain of 3% is applied, and the detection frequency range is set at 0.01-100rad / s, take 3 data points for each order of magnitude in logarithmic mode, set the integration time to 2 cycles, measure the characteristic viscosity value when the angular frequency is 0.01rad / s, and measure the modulus when the phase angle is 63° The measured values are listed in Table 1.

Embodiment 2

[0024] Use a mold to place polyethylene pellets for medical devices on a hot press, melt at 260°C for 9.5 minutes, then apply a pressure of 2.5Mpa and continue hot pressing for 2 minutes, and press to obtain a uniform test sample for use; put the sample under strain The controlled rheometer has a diameter of 25mm on a cone-plate fixture with a cone angle of 5°. The torque accuracy of the rheometer is 0.1nNm, the set temperature is 210°C, the strain is 0.5%, and the detection frequency range is 0.001-600rad / s, take 3 data points for each order of magnitude in logarithmic mode, set the integration time to 2 cycles, measure the characteristic viscosity value when the angular frequency is 0.01rad / s, and measure the modulus when the phase angle is 63° The measured values are listed in Table 1.

Embodiment 3

[0026] Use a mold to place polyethylene pellets for medical devices on a hot press, melt them at 210°C for 8 minutes, then apply a pressure of 2Mpa and continue hot pressing for 3 minutes, and press to obtain a uniform test sample for use; place the sample under strain control On the cone-plate fixture with a diameter of 25mm and a cone angle of 5°, the torque accuracy of the rheometer is 0.1nNm, the set temperature is 205°C, 2% strain is applied, and the detection frequency range is set to 0.01-600rad / s , take 5 data points for each order of magnitude in logarithmic mode, set the integration time to 2 cycles, measure the characteristic viscosity value when the angular frequency is 0.01rad / s, and measure the modulus value when the phase angle is 63° , and list the measured values in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com