Multi-layer quantum dot film and backlight module group

A quantum dot film and quantum dot technology, applied in the field of flat panel display, can solve the problems of poor stability of quantum dot film, reduced luminous efficiency, small color gamut NTSC, etc. Effect of Luminous Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

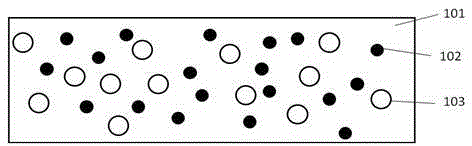

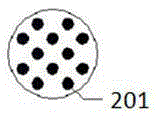

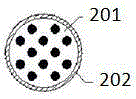

Image

Examples

Embodiment 1

[0038] 1. Preparation of quantum dot core layer

[0039] (1) Preparation of the first quantum dot microcapsule layer

[0040] Organosilicon adsorption red quantum dots with a particle size of 0.5 μm, a pore size of 40 μm, and a pore depth of 5 μm were added to 53.9 parts by weight of polystyrene resin, 1 part by weight of leveling agent, 0.1 part by weight of light curing agent and 5 parts by weight In an adhesive solution composed of 1 part solvent, after UV curing, red quantum dot capsules with a particle size of 1 μm were obtained;

[0041] The particle size is 0.5 μm, the pore size is 40 μm, and the PMMA adsorption green quantum dots with a pore depth of 15 μm is added to 53.9 parts by weight of polystyrene resin, 1 part by weight of leveling agent, 0.1 part by weight of light curing agent and 5 parts by weight of In the adhesive solution that solvent forms, after UV curing, obtain the green quantum dot capsule that particle diameter is 1 μm, get 1 weight part red quantum...

Embodiment 2

[0055] 1. Preparation of quantum dot core layer

[0056] (1) Preparation of the first quantum dot microcapsule layer

[0057] The PMMA adsorption red quantum dots with a particle size of 15 μm, a pore size of 30 μm, and a pore depth of 6 μm were added to 50 parts by weight of polymethyl methacrylate, 2 parts by weight of a leveling agent, 0.2 parts by weight of a crosslinking agent and 15 parts by weight of In an adhesive solution composed of 1 part solvent, after thermal curing, red quantum dot capsules with a particle size of 25 μm were obtained;

[0058] Organosilicon adsorption green quantum dots with a particle size of 15 μm, a pore size of 20 μm, and a pore depth of 6 μm were added to 50 parts by weight of polymethyl methacrylate, 2 parts by weight of a leveling agent, 0.2 parts by weight of a crosslinking agent and 15 parts by weight. In the adhesive solution that parts by weight solvent is formed, after thermal curing, obtain the green quantum dot capsule that particl...

Embodiment 3

[0070] 1. Preparation of quantum dot core layer

[0071] (1) Preparation of the first quantum dot microcapsule layer

[0072] Organosilicon adsorption red quantum dots with a particle size of 20 μm, a pore size of 12 μm, and a pore depth of 20 μm were added to a mixture consisting of 55 parts by weight of polyurethane resin, 5 parts by weight of leveling agent, 0.5 parts by weight of light curing agent and 10 parts by weight of solvent. In the adhesive solution, after UV curing, red quantum dot capsules with a particle size of 25 μm were obtained;

[0073] Add green quantum dots adsorbed by PMMA with a particle size of 20 μm, a pore size of 30 μm, and a pore depth of 20 μm to 55 parts by weight of polyurethane resin, 5 parts by weight of leveling agent, 0.5 parts by weight of light curing agent and 10 parts by weight of solvent. In the adhesive solution, after UV curing, the green quantum dot capsules with a particle size of 25 μm are obtained, and 1 part by weight of the red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com