Device for manufacturing microstructure through focal field trajectory based on dynamic control

A micro-nano structure and dynamic technology, applied in optical components, optics, instruments, etc., can solve the problems of complex movement control of samples, low processing efficiency, etc., and achieve the effects of high repeatability, improved efficiency, and mature technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1. A device for making a microstructure based on a dynamically regulated focal field trajectory

[0028] Such as figure 1As shown, the device for fabricating microstructures using a dynamically regulated femtosecond vector light field array proposed by the present invention includes: a femtosecond laser, a dynamic femtosecond vector light field array generation and regulation system, and a tight-focus micromachining system.

[0029] The generation and control system of the dynamic femtosecond vector light field array includes: a spatial light modulator (4), a 4f system front lens (5), a spatial filter (6), and a 1 / 4 wave plate arranged in sequence along the optical axis (7), 4f system rear lens (8), Ronchi grating (9) and computer system (14) for producing and dynamically controlling the holographic grating. The tightly focused microprocessing system includes: a microscope objective lens (11), a sample (12) and a three-dimensional mobile platform (13).

[0...

Embodiment 2

[0031] Embodiment 2. The principle and method of making microstructures using dynamically regulated femtosecond vector light field arrays

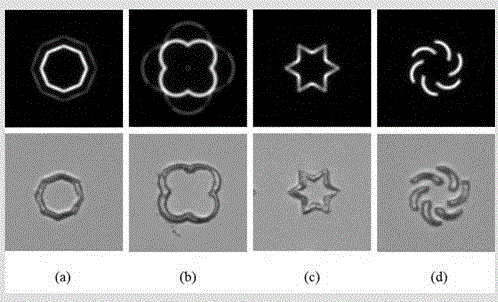

[0032] After the femtosecond laser passes through the generation and control system of the dynamic femtosecond vector light field array described in Example 1, it is incident on the microscope objective lens for focusing, and then incident on the surface or inside of the sample for micro-nano processing, and the prepared micro-nano structure The shape or shape of is determined by the focal spot trajectory of the dynamic vector light field tightly focusing the focal field. The principle of micro-nano-fabrication based on the dynamic vector light field array will be introduced in detail below.

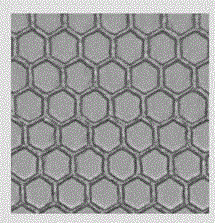

[0033] Such as figure 2 As shown in (a), the vector light field array is composed of a series of single vector light fields arranged according to certain rules. The polarization distribution of each vector light field can be adjusted independently,...

example 1

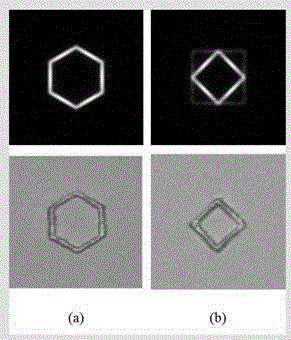

[0047] The following describes in detail the processing of regular hexagonal and regular quadrilateral microstructures inside z-cut lithium niobate crystals in combination with the processing device for making complex microstructures based on the dynamically regulated focal field trajectory of the present invention.

[0048] Processing device reference figure 1 , after the incident femtosecond laser passes through the spatial light modulator and 4f system, based on the principle of wavefront reconstruction, the vector light field is generated by combining the beams of the Ronchi grating. Unlike the generation of a single vector light field, in order to obtain the vector light field array, in The holographic grating loaded on the spatial light modulator is also an array type, the grating has the same period and orientation, and the arrangement mode of the holographic grating has the same arrangement as the vector light field array to be generated (see figure 2 (a) shown). Whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com