Adjustable and controllable preparation method for large-area nanometer microstructure of fused quartz optical curved face

A technology of fused silica and microstructure, which is applied in the field of nano-manufacturing, can solve the problems of accurate control and inability to realize the cycle of microstructure, and achieve the effect of improving performance, low requirements for motion resolution and positioning accuracy, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

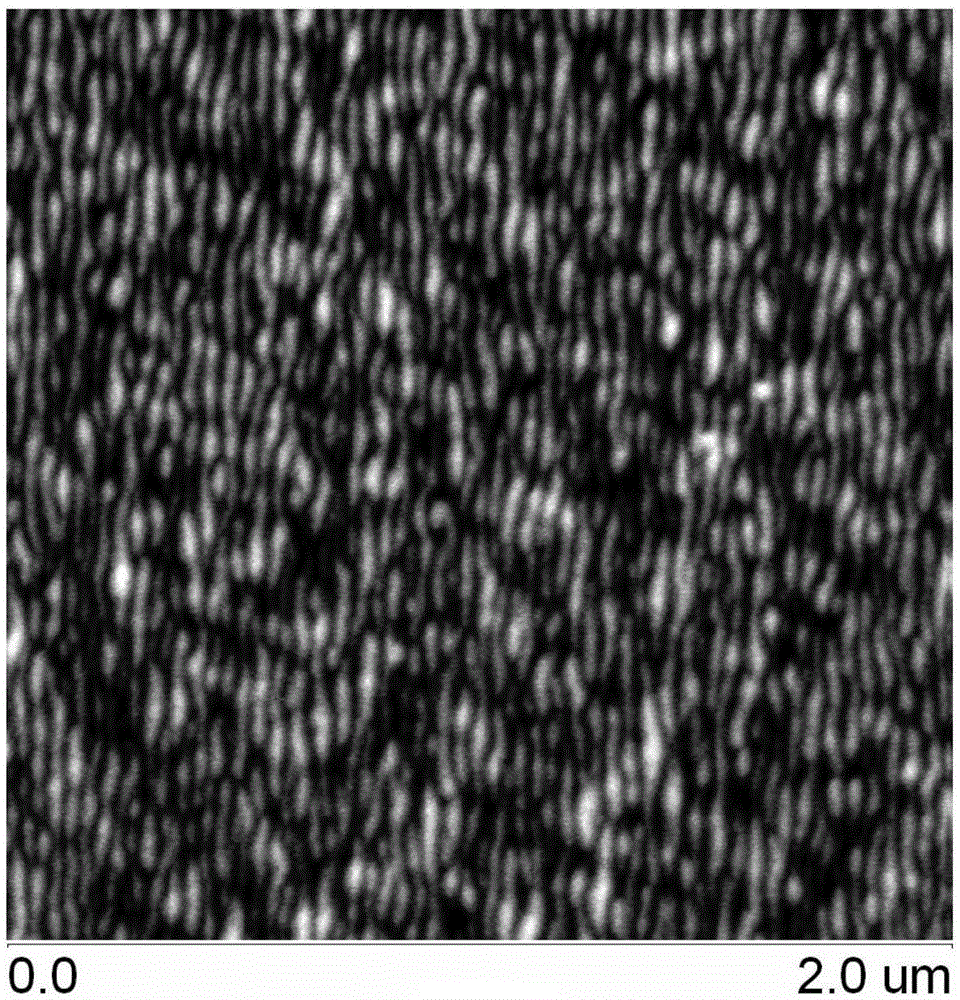

Examples

Embodiment Construction

[0038] The following will be based on the caliber The fused silica optical curved surface optical part with a vertex curvature radius of 16 mm is used as the fused silica optical curved surface optical part to be processed, and the method for preparing the large-area nano-microstructure control of the fused silica optical curved surface of the present invention is further specifically described.

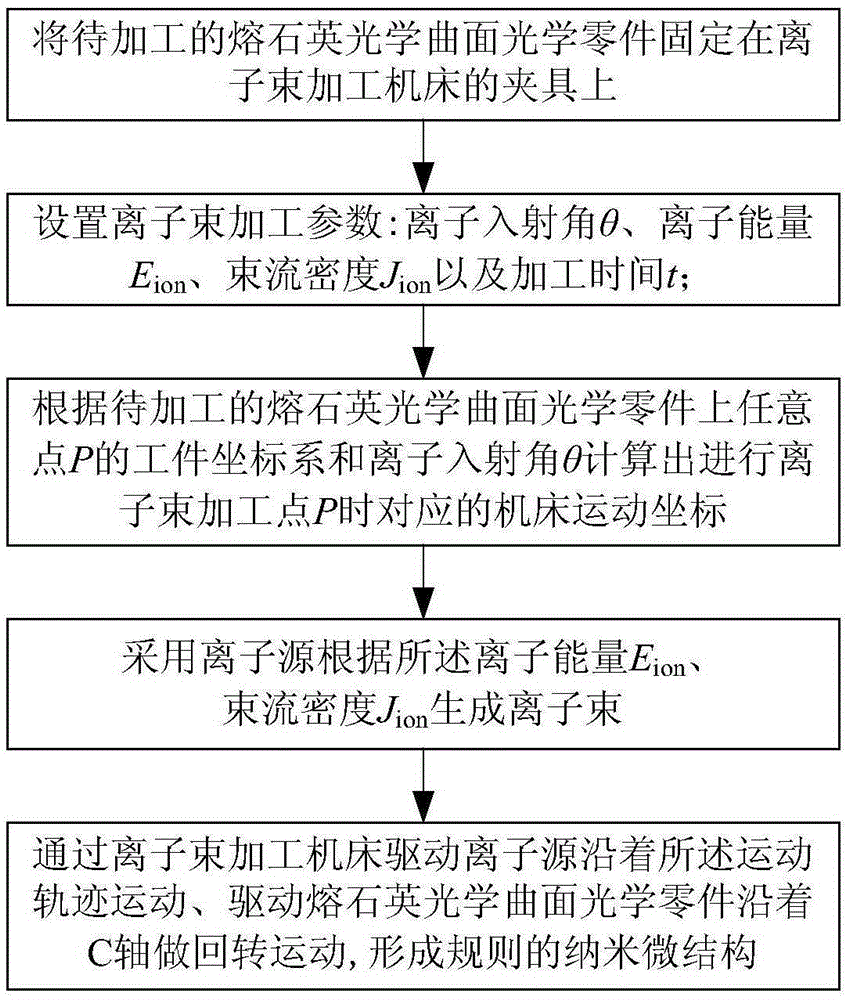

[0039] Such as figure 1 As shown, the steps of the large-area nano-microstructure control preparation method of the fused silica optical curved surface in this embodiment include:

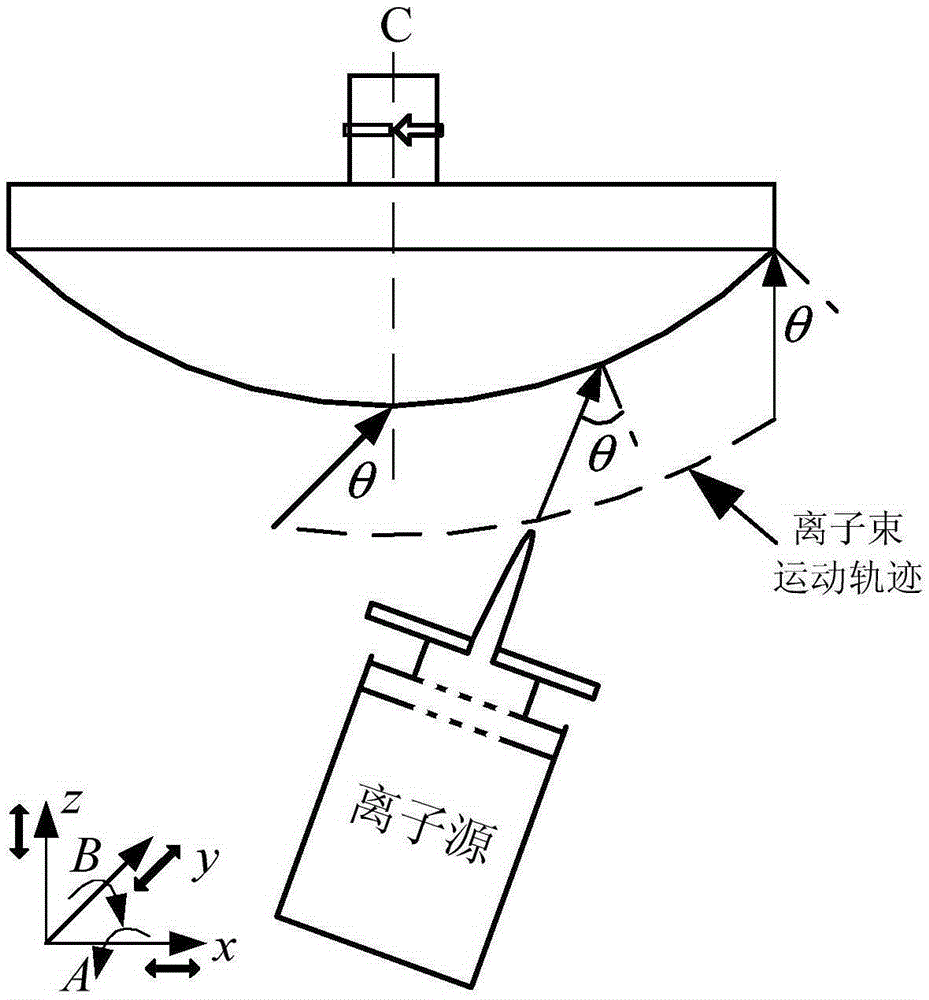

[0040] 1) Fix the fused silica optical curved surface optical part to be processed on the fixture of the ion beam processing machine tool, and the fixture is connected to the ion beam processing machine tool through a motor that can drive the fused silica optical curved surface optical part to perform rotary motion along the C axis ,Such as figure 2 shown;

[0041] 2) set the ion beam processing para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com