Preparation method of porous Ti3C2/g-C3N4 composite film material

A composite film, g-c3n4 technology, applied in the field of preparation of nanomaterials, can solve problems such as unseen research patents and literature reports, and achieve the effects of easy industrialized large-scale production, mild and easily controllable conditions, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

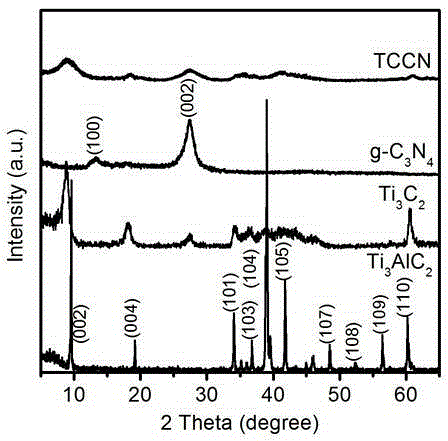

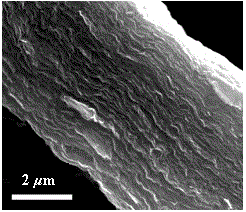

Embodiment 1

[0021] Weigh 5 grams of Ti 3 AlC 2 Put it into a plastic reaction container, slowly add 40 ml of hydrofluoric acid with a concentration of 49%, shake it for 10 minutes while adding, and react in a water bath at 60°C for 16 hours to obtain the reaction solution, which is centrifuged, washed and filtered in sequence to obtain filter residue, and the pH value of the filtered filtrate is 4, and the obtained filter residue is dried at 70° C. for 6 hours to obtain Ti 3 C 2 Powder; in air atmosphere, heat dicyandiamide from room temperature to 550 °C at a heating rate of 2.3 °C / min, keep at 550 °C for 3 hours and then cool to room temperature to obtain g-C 3 N 4 powder; the above prepared Ti 3 C 2 Powder and g-C 3 N 4 The powder is mixed according to a mass ratio of 5:1 to obtain a mixed powder, and the mixed powder is dispersed into a mixed solution of 100 milliliters of deionized water and isopropyl ketone to obtain a mixed suspension, wherein the volume ratio of deionized w...

Embodiment 2

[0023] Weigh 5 grams of Ti 3 AlC 2 Put it into a plastic reaction container, slowly add 60 ml of hydrofluoric acid with a concentration of 49%, shake it for 20 minutes while adding, and react in a water bath at 60°C for 24 hours to obtain the reaction solution, which is centrifuged, washed and filtered in sequence to obtain filter residue, and the pH value of the filtrate after filtration is 5, and the obtained filter residue is dried at 70° C. for 10 hours to obtain Ti 3 C 2 Powder; in air atmosphere, heat dicyandiamide from room temperature to 550 °C at a heating rate of 2.3 °C / min, keep at 550 °C for 6 hours and then cool to room temperature to obtain g-C 3 N 4 powder; the above prepared Ti 3 C2 Powder and g-C 3 N 4 The powder is mixed according to a mass ratio of 5:4 to obtain a mixed powder, and the mixed powder is dispersed into a mixed solution of 100 milliliters of deionized water and isopropyl ketone to obtain a mixed suspension, wherein the volume ratio of deio...

Embodiment 3

[0025] Weigh 5 grams of Ti 3 AlC 2 Put it into a plastic reaction container, slowly add 50 ml of hydrofluoric acid with a concentration of 49%, shake it for 15 minutes while adding, and react in a water bath at 60°C for 19 hours to obtain a reaction solution, which is centrifuged, washed and filtered in sequence to obtain filter residue, and the pH value of the filtered filtrate is 4.5, and the obtained filter residue is dried at 70° C. for 10 hours to obtain Ti 3 C 2 Powder; in air atmosphere, heat dicyandiamide from room temperature to 550 °C at a heating rate of 2.3 °C / min, keep at 550 °C for 5 hours and then cool to room temperature to obtain g-C 3 N 4 powder; the above prepared Ti 3 C 2 Powder and g-C 3 N 4 The powder is mixed according to a mass ratio of 5:3 to obtain a mixed powder, and the mixed powder is dispersed into a mixed solution of 100 milliliters of deionized water and isopropyl ketone to obtain a mixed suspension, wherein the volume ratio of the deioni...

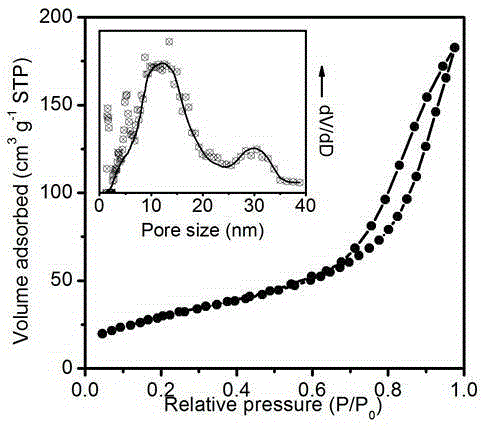

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com