A low-pressure exhaust steam recovery and utilization system

A technology of spent steam recovery and low pressure, applied in the field of low pressure spent steam recovery and utilization technology and system, can solve the problem of large amount of spent steam discharged to the atmosphere, reduced heat transfer capacity of heat exchanger scaling, personal safety and equipment corrosion and environmental pollution And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

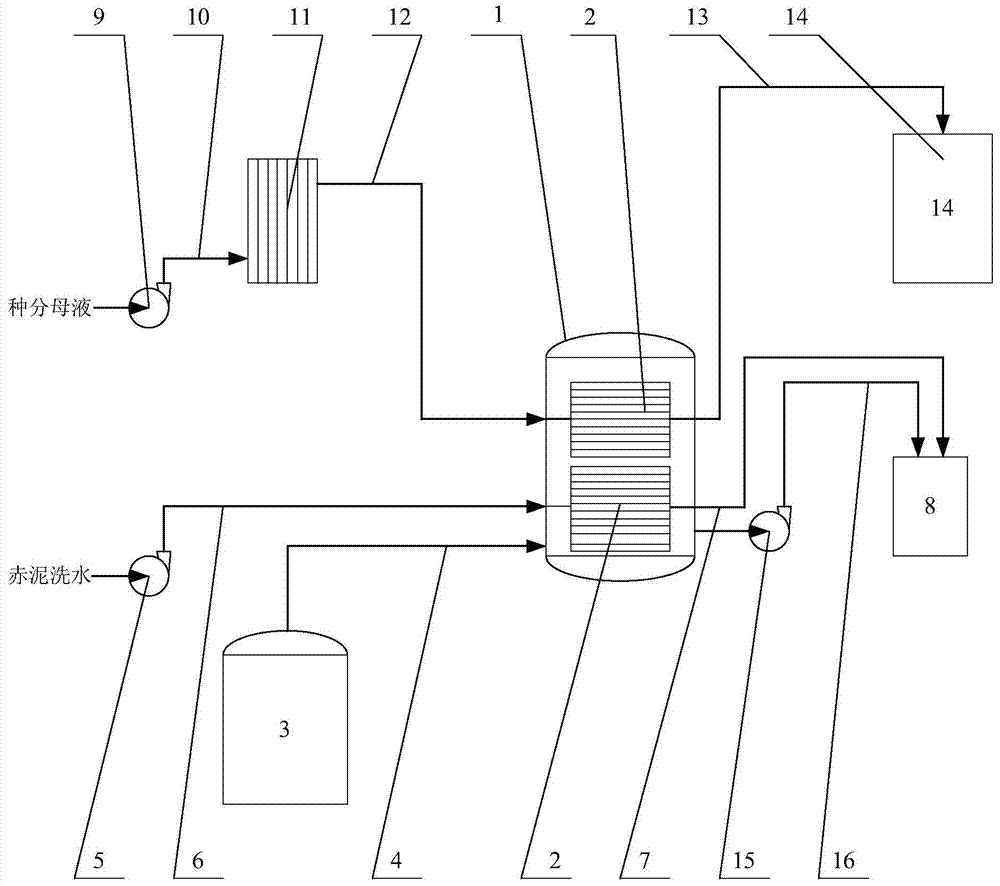

[0015] As shown in the drawings, the low-pressure exhaust steam recycling system of the present invention is provided with a low-pressure container 1, and one to four heat exchangers 2 are installed in the low-pressure container, and the present embodiment is two. The excess low-pressure exhaust steam in the dilution tank 3 enters the low-pressure container 1 through the low-pressure exhaust steam pipe 4, condenses on the surface of the heat exchanger 2, and transfers heat to the low-temperature material in the inner tube of the heat exchanger.

[0016] The red mud washing low-temperature water pump 5 sends the red mud washing low-temperature water to the heat exchanger 2 through the red mud washing low-temperature water pipe 6, and the red mud washing high-temperature hot water heated to about 95°C enters the red mud washing hot water through the red mud washing high-temperature water pipe 7 Sink8.

[0017] The seed separation mother liquor pump 9 sends the seed separation mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com