Method for preparing zirconium oxide aerogel through combination of secondary gelling method and ambient-pressure drying

An atmospheric drying and aerogel technology, applied in zirconia and other directions, can solve the problems of expensive equipment, high cost, and difficulty in large-scale production, and achieve the effect of improving the strength of the skeleton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

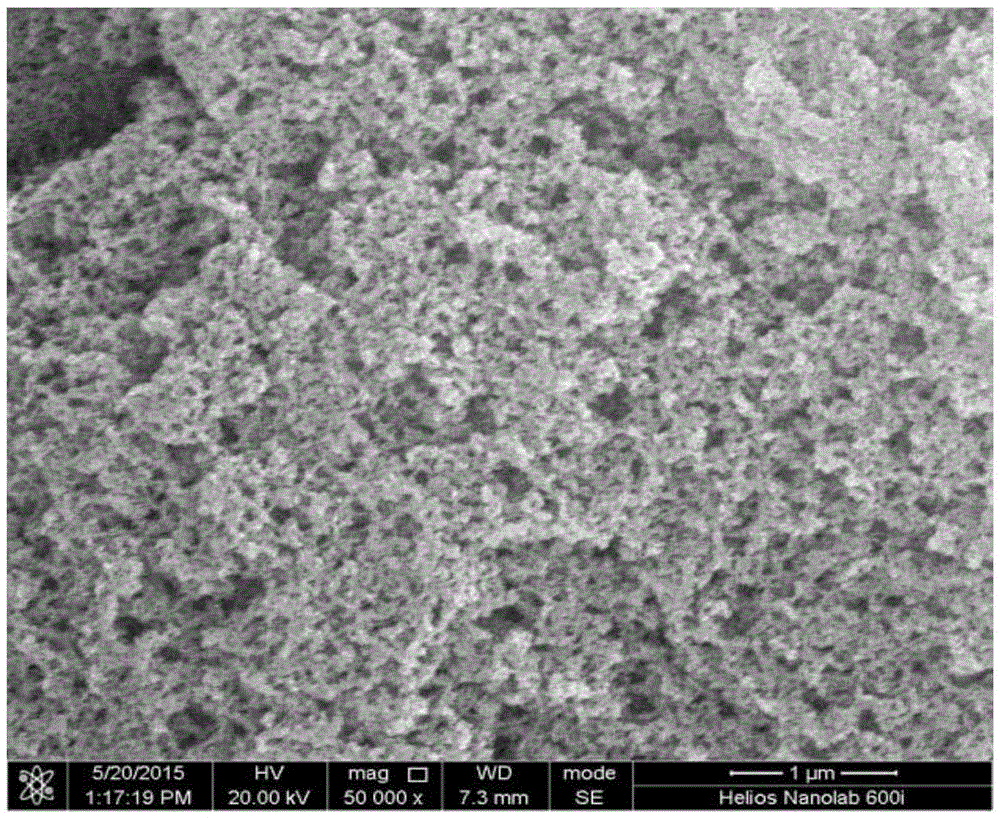

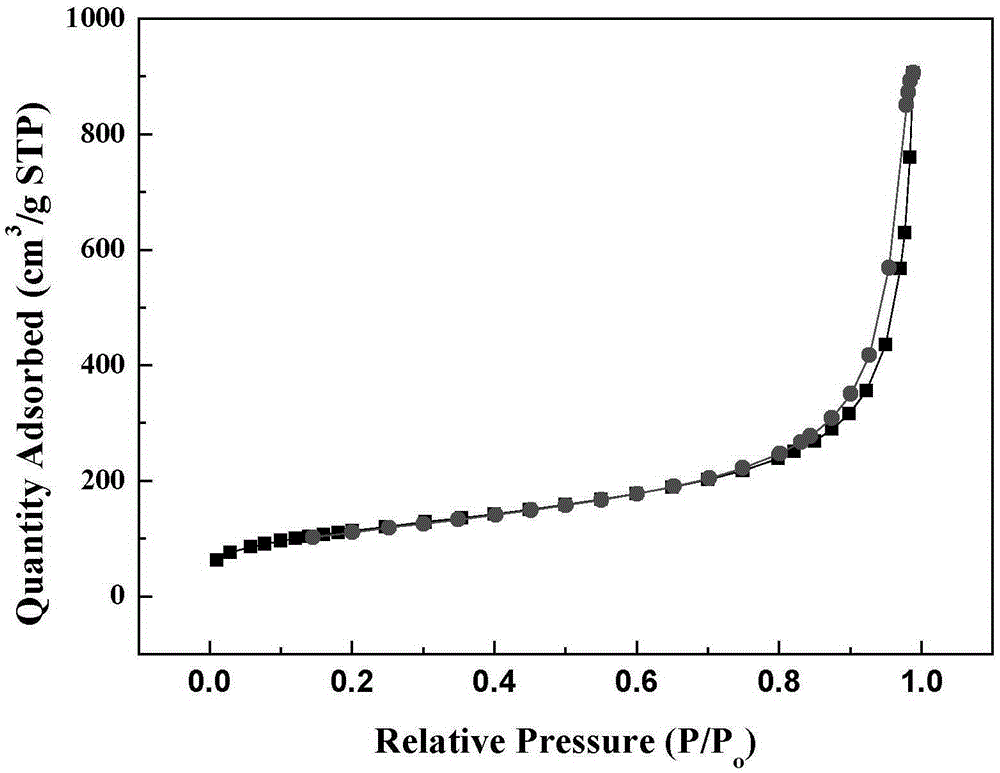

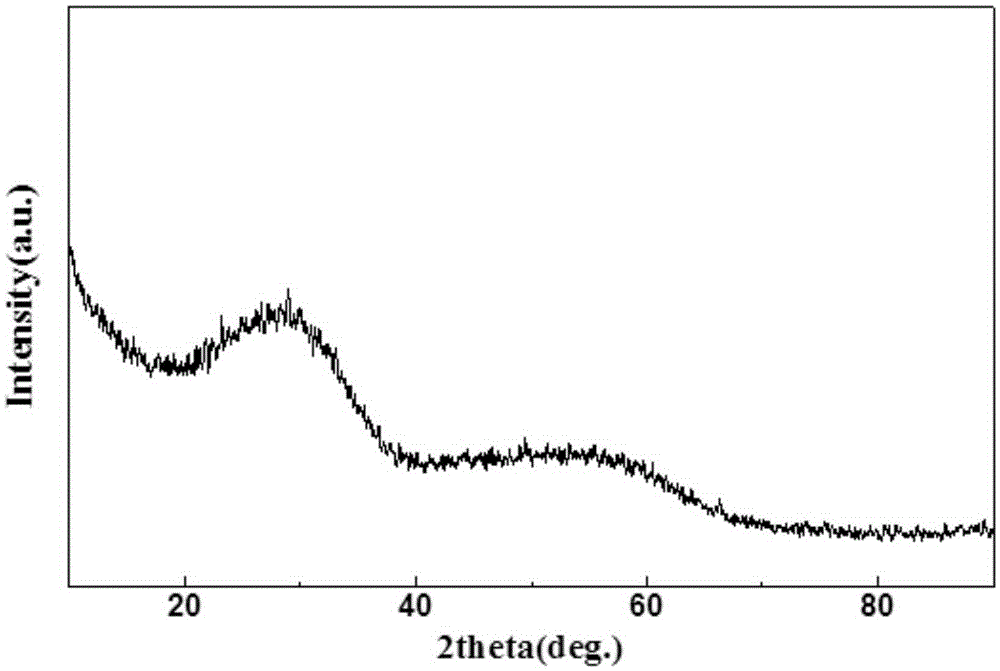

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: In this embodiment, the method for preparing zirconia airgel by secondary gel method combined with normal pressure drying is carried out according to the following steps:

[0026] 1. Preparation of zirconia wet gel

[0027] Under stirring conditions, the ZrO(NO) 3 2H 2 Dissolve O in an alcoholic water solvent to make a transparent solution with a zirconyl nitrate concentration of 4.9-5.1wt%, then add formamide dropwise to the solution to obtain a mixed solution, and put the mixed solution in a water bath at a temperature of 60°C In a water bath, add ammonia water drop by drop to adjust the pH of the mixture to 8.7-9.3, then increase the stirring rate, stop stirring after 5-8 minutes, the gel is in a thick soup state, and continue to bathe at 60°C;

[0028] 2. ZrO 2 Regelation and Modification of Thick Gel

[0029] Transfer the thick soup-like gel prepared in step 1 to an oven at 43-47°C for aging until a wet gel solid is formed for the secon...

specific Embodiment approach 2

[0032] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 1, a transparent solution with a zirconyl nitrate concentration of 5 wt % is prepared. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the alcohol-water solvent in Step 1 is made of absolute ethanol and water at a volume ratio of 2.8-3.2:1. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com