A kind of endogenous antibiotic waste water treatment process system

A technology for antibiotic wastewater and treatment process, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of reducing the dosage of chemicals and power consumption, saving economic costs, and strongly resisting changes in water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

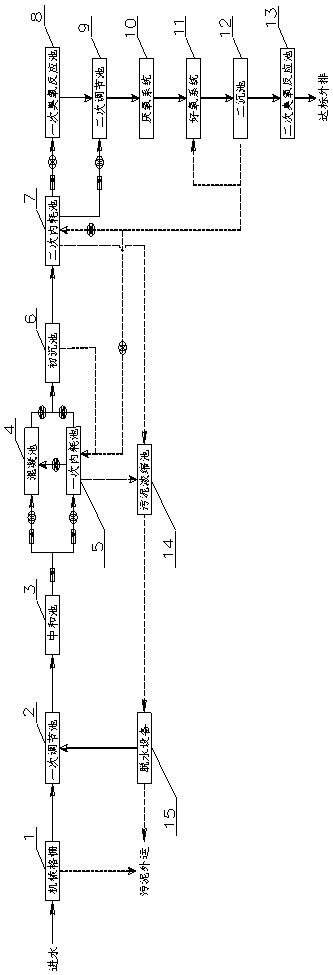

[0025] In order to better understand the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, and the following examples are only to illustrate the present invention rather than limit it.

[0026] Such as figure 1 As shown, an internal consumption antibiotic wastewater treatment process system is mainly composed of a mechanical grid 1, a primary adjustment tank 2, a neutralization tank 3, a coagulation tank 4, a primary internal consumption tank 5, a primary sedimentation tank 6, and a secondary internal consumption tank 7 , Primary ozone reaction tank 8, secondary adjustment tank 9, anaerobic system 10, aerobic system 11, secondary sedimentation tank 12, secondary ozone reaction tank 13, sludge thickening tank 14, dehydration equipment 15, etc.

[0027] The antibiotic waste water is firstly discharged into the mechanical grid 1 through the sewage collection pipe network to remove larger suspended ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com