Cement for cementing fireflood thickened oil thermal production well

A technology for thermal recovery well cementing and heavy oil thermal recovery, which is applied in the field of cementing cement, can solve the problems of poor high temperature resistance, short service life, and low strength of cement, and achieve good high temperature resistance, long service life, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with embodiment.

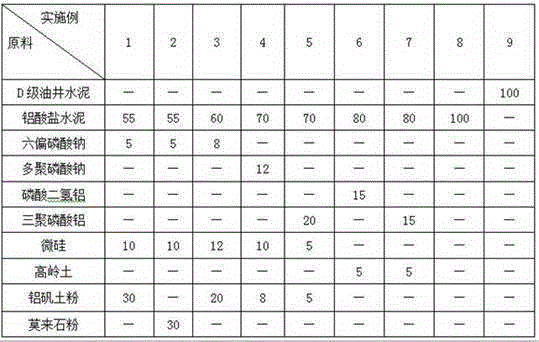

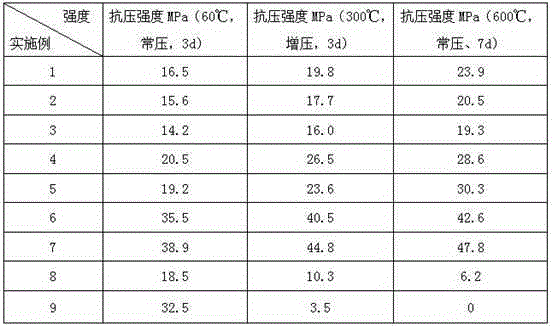

[0028] Among the following examples, examples 1 to 7 are the cementing cements for fire-flooding heavy oil thermal recovery wells of the present invention, and examples 8 and 9 are comparative examples, which are G-grade oil well cement and aluminate cement respectively. The specific formulations are as follows: Table 1 below.

[0029] Table 1:

[0030]

[0031] In the above examples, aluminate cement was produced by Zhengzhou Jianai Special Aluminate Co., Ltd., sodium hexametaphosphate and sodium polyphosphate were produced by Sichuan Jinshi Phosphorus Chemical Co., Ltd., and aluminum dihydrogen phosphate was produced by Zhengzhou Yucai Phosphate Chemical Plant. Production, aluminum tripolyphosphate is produced by Shijiazhuang Xinsheng Chemical Co., Ltd.; kaolin is provided by Zhongshi Hengda Mineral Products Processing Plant in Lingshou County, and bauxite powder is provided by Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com