Method for adjusting and controlling surface wrinkling or wrinkle removing through oxidation-reduction environment

An environmental and anti-wrinkle technology, which is applied in the field of regulating polyaniline surface wrinkle patterns, can solve problems that are not involved in the intelligent interface, and achieve the effects of simple operability, reversible regulation, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of a wrinkled PANI film uniformly grown on the PDMS surface includes the following steps:

[0027] Step 1. Mix the PDMS prepolymer and cross-linking agent according to a certain mass ratio, pour it into a vessel, and stir it fully with a glass rod to obtain a uniform prepolymer;

[0028] Step 2. After degassing the prepolymer obtained in step 1 in a vacuum dryer for 1 hour, place it in a constant temperature blast drying oven at 70 degrees Celsius and heat it for 4 hours for curing to obtain a PDMS elastomer;

[0029] Step 3. Cut the PDMS elastomer obtained in step 2 into 3cm×1cm PDMS elastomer strip samples for later use;

[0030] Step 4, preparing 0.1M aniline hydrochloric acid solution and 0.1M ammonium persulfate hydrochloric acid solution respectively, respectively placing the aniline hydrochloric acid solution and ammonium persulfate hydrochloric acid solution at 0-5 degrees Celsius for 30 minutes;

[0031] Step 5. Quickly mix the two solutions pr...

Embodiment 2

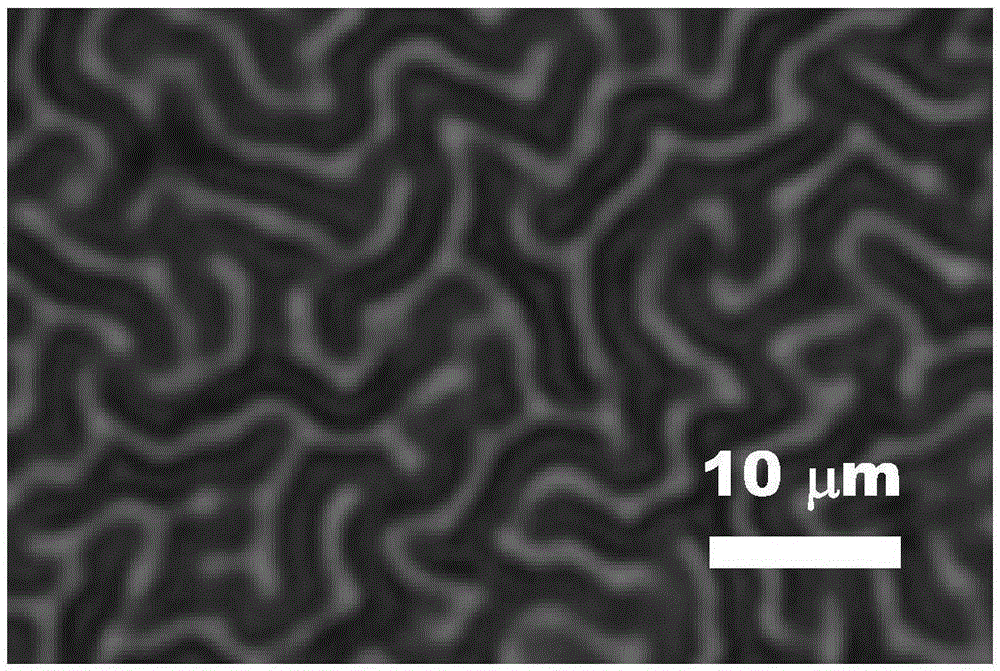

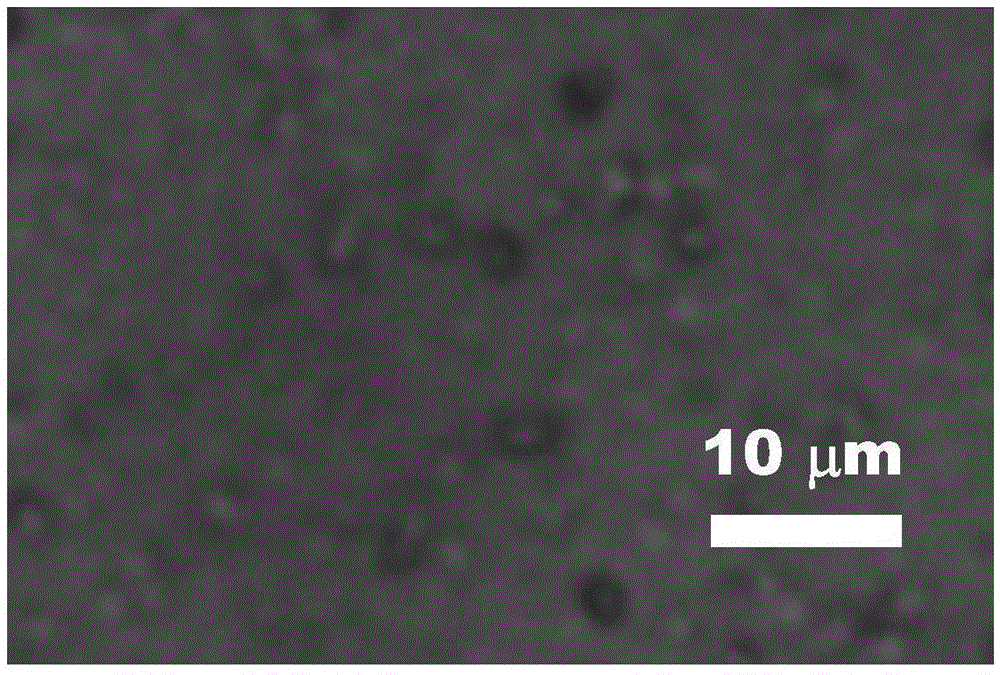

[0033] A method for regulating surface wrinkling or wrinkling utilizing a redox environment is to place the PANI wrinkle film obtained in Example 1 in a 0.1M reducing sodium borohydride solution for 2 seconds and then take it out to obtain a PANI wrinkle appearance disappearance. Membrane, optical microscope picture as figure 2 shown. The above-mentioned wrinkle-free PANI film is placed in the oxidative hydrogen peroxide solution of mass fraction 15wt% and taken out after 1 minute, and the optical microscope picture of the wrinkled PANI film is obtained again as follows: figure 1 shown.

Embodiment 3

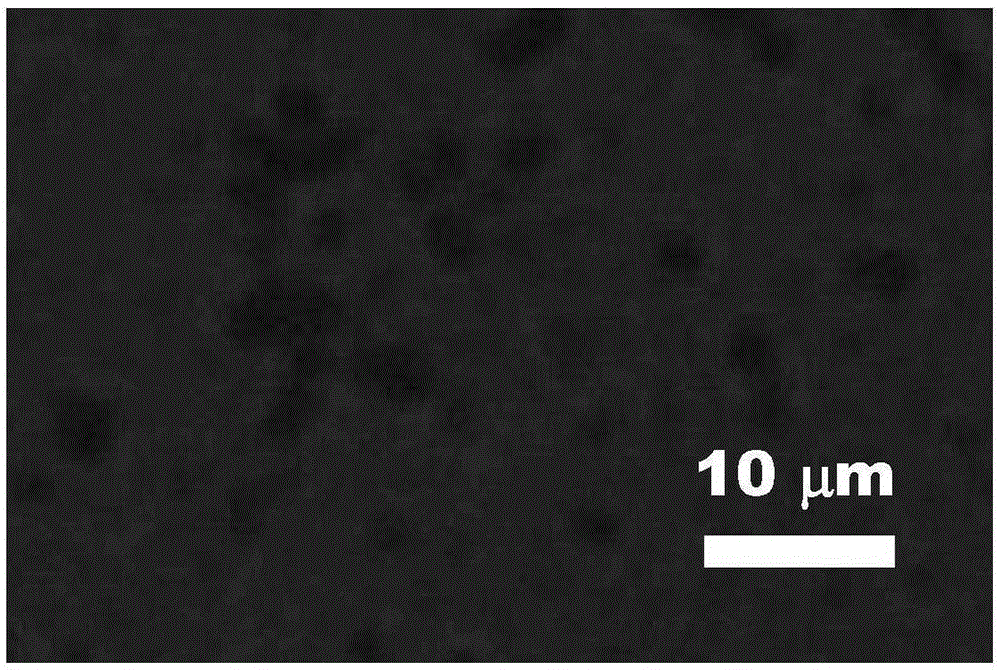

[0035] A method for regulating surface wrinkling or wrinkling utilizing a redox environment, the PANI wrinkle film obtained in Example 1 is placed in 0.1M oxidative potassium persulfate solution for 5 seconds and then taken out to obtain a PANI film whose wrinkle appearance disappears , an optical microscope picture such as image 3 shown. The above-mentioned non-wrinkled PANI film is placed in 1M hydrochloric acid solution and taken out after 1 minute, and the optical microscope picture of the wrinkled PANI film is obtained again. figure 1 shown.

[0036] In summary, the method of the present invention mainly grows wrinkled PANI film in situ on the PDMS substrate, and utilizes different redox environments to achieve reversible regulation of surface wrinkles. Because the PANI film is in different swelling and shrinking states in different environments, resulting in a reversible change in volume, and then realizes a reversible change in wrinkling / wrinkling of the pattern. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com