Weather-resistant paint for external walls and preparation method

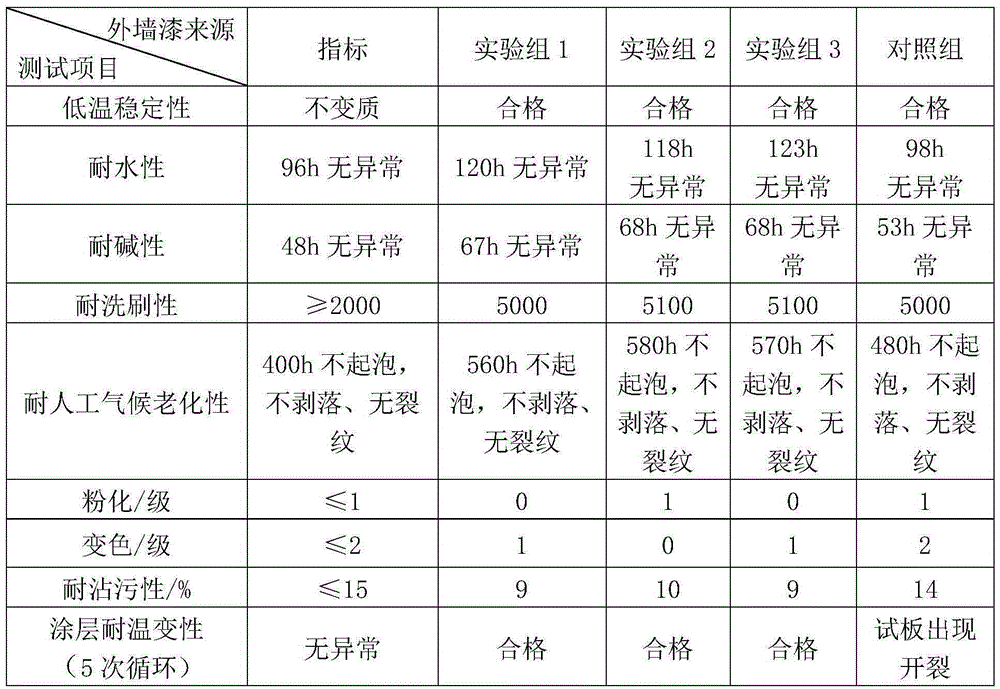

A technology for exterior wall paint and weather resistance, applied in the field of wall paint, can solve the problems of discoloration, chalking, poor weather resistance of exterior wall paint, affecting decorative effect and use value, etc., and achieves improvement of temperature resistance and weather resistance of coatings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A weather-resistant exterior wall paint, which consists of the following components: 5kg of hydroxypropyl methylcellulose, 15kg of wollastonite powder with a mass fraction of silicon dioxide not less than 58%, 25kg of calcined kaolin, 12kg of styrene-acrylic emulsion, 5kg of disperse Agent polyvinyl alcohol 400, 1kg anti-settling agent, 2kg anti-mold agent, 1.5kg water-based acid alcohol resin defoamer and 35kg water.

[0033] The preparation method of this weather-resistant exterior wall paint is:

[0034] A. Weigh according to the ratio of raw materials and reserve;

[0035] B. Add water to the mixer, then add calcined kaolin, wollastonite powder and dispersant in sequence, and stir at 680 rpm for 15 minutes at 40°C;

[0036] C. Add styrene-acrylic emulsion, cellulose, anti-foaming agent, anti-fungal agent and anti-sedimentation agent to the mixture obtained in step B, and stir at 780 rpm for 10 minutes at 25°C.

Embodiment 2

[0038] A weather-resistant exterior wall paint, consisting of the following components: 10kg of hydroxypropyl methylcellulose, 6kg of wollastonite powder with a mass fraction of silicon dioxide not less than 58%, 15kg of calcined kaolin, 18kg of styrene-acrylic emulsion, 3kg of disperse Agent polyethylene glycol 200, 3kg anti-settling agent, 5kg anti-mold agent, 0.5kg water-based acid alcohol resin defoamer and 25kg water.

[0039] The preparation method of this weather-resistant exterior wall paint is:

[0040] A. Weigh according to the ratio of raw materials and reserve;

[0041] B. Add water to the mixer, then add calcined kaolin, wollastonite powder and dispersant in sequence, and stir at 730 rpm for 20 minutes at 35°C;

[0042] C. Add styrene-acrylic emulsion, cellulose, antifoaming agent, antifungal agent and anti-sedimentation agent to the mixture obtained in step B, and stir at 7500 rpm for 15 minutes at 30°C.

Embodiment 3

[0044] A weather-resistant exterior wall paint, which consists of the following components: 8kg of hydroxypropyl methylcellulose, 9kg of wollastonite powder with a mass fraction of silicon dioxide not less than 58%, 18kg of calcined kaolin, 15kg of styrene-acrylic emulsion, 4kg of disperse Agent polyethylene glycol 200, 2kg anti-settling agent, 3kg anti-mold agent, 1kg water-based acid alcohol resin defoamer and 30kg water.

[0045] The preparation method of this weather-resistant exterior wall paint is:

[0046] A. Weigh according to the ratio of raw materials and reserve;

[0047] B. Add water to the mixer, then add calcined kaolin, wollastonite powder and dispersant in sequence, and stir at 720 rpm for 18 minutes at 36°C;

[0048] C. Add styrene-acrylic emulsion, cellulose, antifoaming agent, antifungal agent and anti-sedimentation agent to the mixture obtained in step B, and stir at 760 rpm for 12 minutes at 28°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com