Epoxy resin curing agent capable of improving anti-ultraviolet performance of epoxy resin and preparation method for epoxy resin curing agent

An epoxy resin curing and anti-ultraviolet technology, which is applied in the field of materials, can solve the problems that the anti-ultraviolet performance of epoxy resin cannot achieve good results, reduce the anti-ultraviolet performance of materials, and poor anti-ultraviolet performance, so as to improve the anti-ultraviolet performance, Improve the anti-ultraviolet performance and reduce the effect of external migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

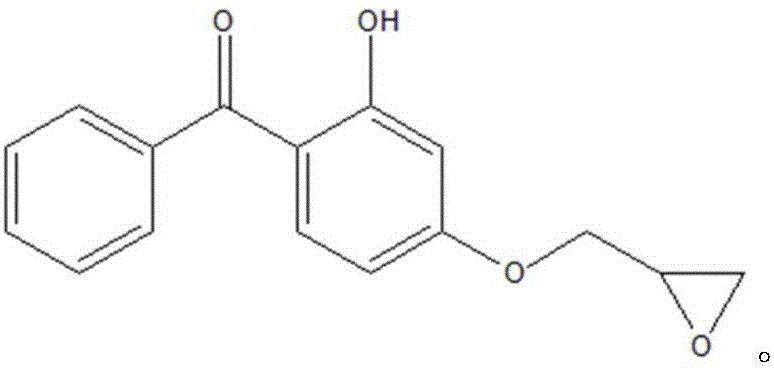

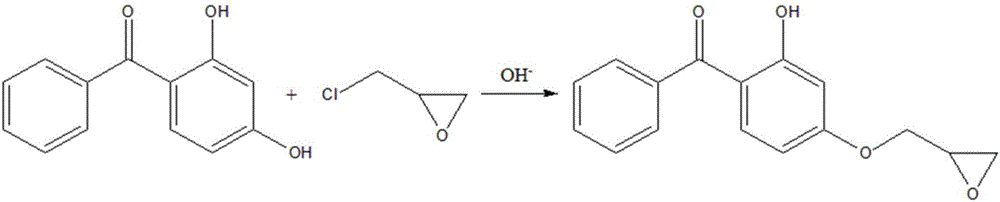

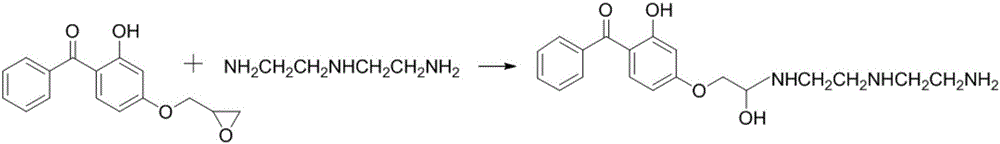

[0022] 1) Synthesis of UV absorber molecule 2-hydroxy-4-(2,3-ethylene oxide glycidyl ether)-benzophenone (HEPBP)

[0023] Add 21.49 grams (0.1mol) of 2,4-dihydroxybenzophenone (UV-0) and 46.25 grams (0.5mol) of epichlorohydrin into a 250mL three-necked flask equipped with a stirring motor, a thermometer and a reflux condenser , heated to 88°C, 9.6 grams of 50% sodium hydroxide aqueous solution (the content of sodium hydroxide in which is 0.12mol) was added dropwise to the three-necked flask, stirred vigorously, and then kept stirring at a constant temperature of 88°C for 2h After the reaction, the product was repeatedly washed with hot water at 60°C, dried with anhydrous sodium sulfate for half an hour, and then excess epichlorohydrin in the product was evaporated under reduced pressure, and finally recrystallized with ethanol to obtain light yellow needle-like crystals. It is the ultraviolet absorber molecule 2-hydroxyl-4-(2,3-ethylene oxide glycidyl ether)-benzophenone (HEPB...

Embodiment 2

[0034] 1) Synthesis of UV absorber molecule 2-hydroxy-4-(2,3-ethylene oxide glycidyl ether)-benzophenone (HEPBP)

[0035] Add 2,4-dihydroxybenzophenone and epichlorohydrin at a molar ratio of 0.5:1 into a three-necked flask equipped with a stirring motor, a thermometer and a reflux condenser, heat to 85°C, and drop into the three-necked flask Add an aqueous solution of sodium hydroxide with a mass fraction of 40% (the molar ratio of sodium hydroxide to 2,4-dihydroxybenzophenone is 1:1), stir vigorously, and then continue to stir and react at a constant temperature of 85°C for 3h. After the reaction, the product was repeatedly washed with hot water at 65°C, dried with anhydrous sodium sulfate for half an hour, and then excess epichlorohydrin in the product was evaporated under reduced pressure, and finally recrystallized with ethanol to obtain light yellow needle-like crystals, namely It is the ultraviolet absorber molecule 2-hydroxyl-4-(2,3-ethylene oxide glycidyl ether)-benzo...

Embodiment 3

[0039] 1) Synthesis of UV absorber molecule 2-hydroxy-4-(2,3-ethylene oxide glycidyl ether)-benzophenone (HEPBP)

[0040] Add 2,4-dihydroxybenzophenone and epichlorohydrin at a molar ratio of 0.1:1 into a three-necked flask equipped with a stirring motor, a thermometer and a reflux condenser, heat to 90°C, and drop into the three-necked flask Add an aqueous solution of sodium hydroxide with a mass fraction of 20% (the molar ratio of sodium hydroxide to 2,4-dihydroxybenzophenone is 0.5:1), stir vigorously, and then continue to stir and react at a constant temperature of 90°C for 0.5h After the reaction, the product was repeatedly washed with hot water at 70°C, dried with anhydrous sodium sulfate for half an hour, and then excess epichlorohydrin in the product was evaporated under reduced pressure, and finally recrystallized with ethanol to obtain light yellow needle-like crystals. That is, the ultraviolet absorber molecule 2-hydroxyl-4-(2,3-ethylene oxide glycidyl ether)-benzop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com