Sand solidification method

A sand-fixing method and desert technology, applied in the field of sand-fixing, can solve the problems of low construction efficiency, unsatisfactory effect, labor-intensive and time-consuming, etc., achieve the effects of reducing sand and dust, realizing large-scale promotion and application, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Wind Tunnel Experiments on Sand in the Desert

[0030] Take the sand in the desert as a sample, fill it with 5 plastic discs with a size of Φ20cm×4cm, and smooth it along the upper edge of the disc with a glass rod. Mix 10 parts of vinyl acetate-n-butyl acrylate copolymer emulsion and 90 parts of water evenly, according to 1kg / m 2 The dosage is sprayed on the sand surface, dried and put into the wind tunnel. Take the blowing erosion angles as 0°, 15°, and 30° respectively, and blow and etch for 10 minutes at a wind speed of 15-16m / s. The wind erosion weight of the test samples is 0-4wt%, and the surface integrity rate of the consolidated layer of all samples reaches 92.3%.

Embodiment 2

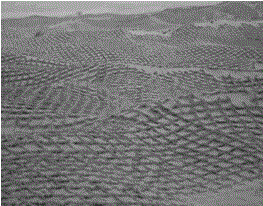

[0031] Example 2 Field sand fixation and weathering test

[0032] The test area is about 20m 2 , Take 8 parts of vinyl acetate-tert-butyl acrylate emulsion and mix them evenly with 92 parts of water, according to 1kg / m 2 Sprayed on the surface of sand grains, the consolidated layer of the sample remained undamaged for 12 months under various natural conditions in the field. see Figure 4 .

[0033]Adopt vinyl acetate-ethylene-tertiary carbonic acid ethylene ester, vinyl acetate-tertiary carbonic acid ethylene ester-maleic acid ester, vinyl acetate-ethylene-acrylate tertiary copolymer (the vinyl acetate-ethylene- Acrylate terpolymers are vinyl acetate monomer, vinyl monomer and n-butyl acrylate, isobutyl acrylate, isopropyl acrylate, tert-butyl acrylate, cyclohexyl acrylate, allyl acrylate, benzene acrylate methyl ester, octyl acrylate, isooctyl acrylate, hydroxyethyl acrylate or hydroxypropyl acrylate, copolymers of one or more monomers), and vinyl acetate-acrylate binar...

Embodiment 3

[0035] Example 3 Laying desert pavement test

[0036] Due to the small friction between sand grains, walking in the desert is more strenuous than on hard ground. Take 10 parts of vinyl acetate-isopropyl acrylate emulsion and 90 parts of water and mix evenly, according to 2kg / m 2 The dosage is sprayed on the sand surface of a certain desert in northern my country to form a sidewalk. After natural drying and hardening, adults can walk freely on it, and the sand will not collapse.

[0037] Adopt vinyl acetate-ethylene-tertiary carbonic acid ethylene ester, vinyl acetate-tertiary carbonic acid ethylene ester-maleic acid ester, vinyl acetate-ethylene-acrylate tertiary copolymer (the vinyl acetate-ethylene- Acrylate terpolymers are vinyl acetate monomer, vinyl monomer and n-butyl acrylate, isobutyl acrylate, isopropyl acrylate, tert-butyl acrylate, cyclohexyl acrylate, allyl acrylate, benzene acrylate methyl ester, octyl acrylate, isooctyl acrylate, hydroxyethyl acrylate or hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com