Oil field water injection automatic control system and method thereof

An automatic control system, oil field water injection technology, applied in electrical program control, program control in sequence/logic controller, earthwork drilling and other directions, can solve the problem of inability to track changes in production parameters in time, improper adjustment of operating parameters, and waste of throttling and other problems, to achieve the effect of good real-time adjustment, reduction of manual intervention, and reduction of operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

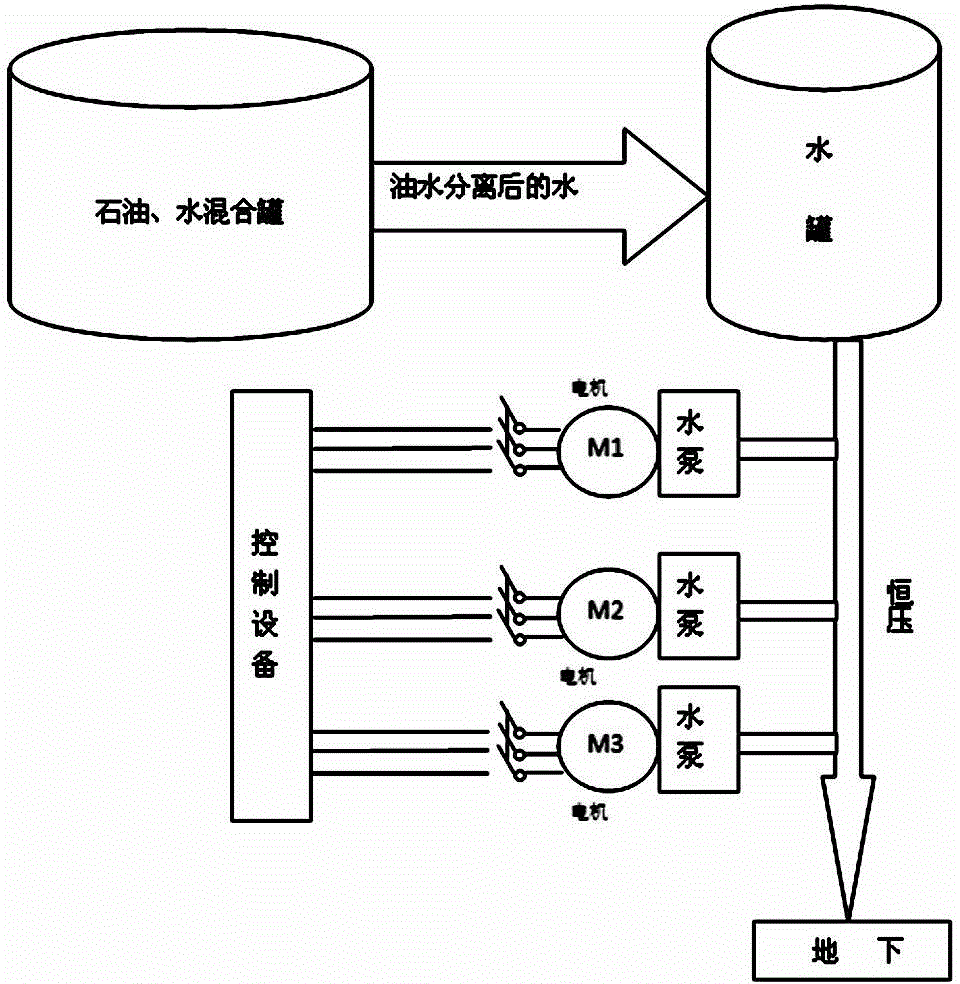

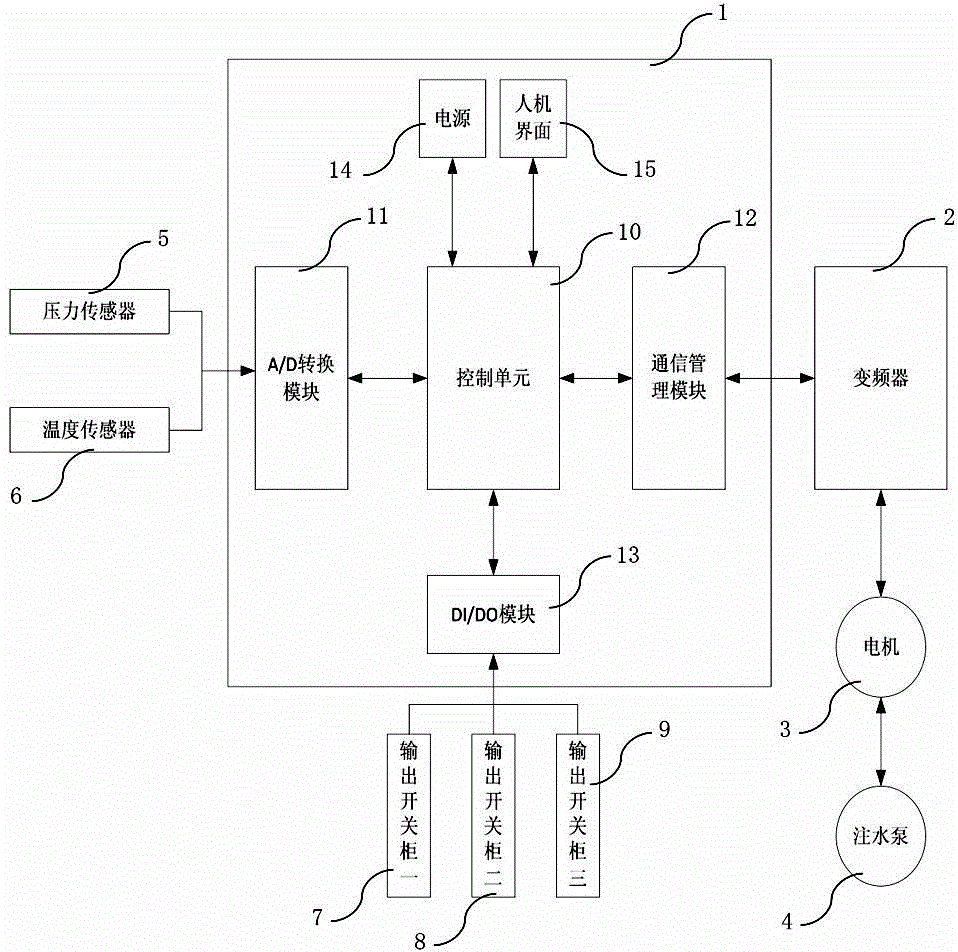

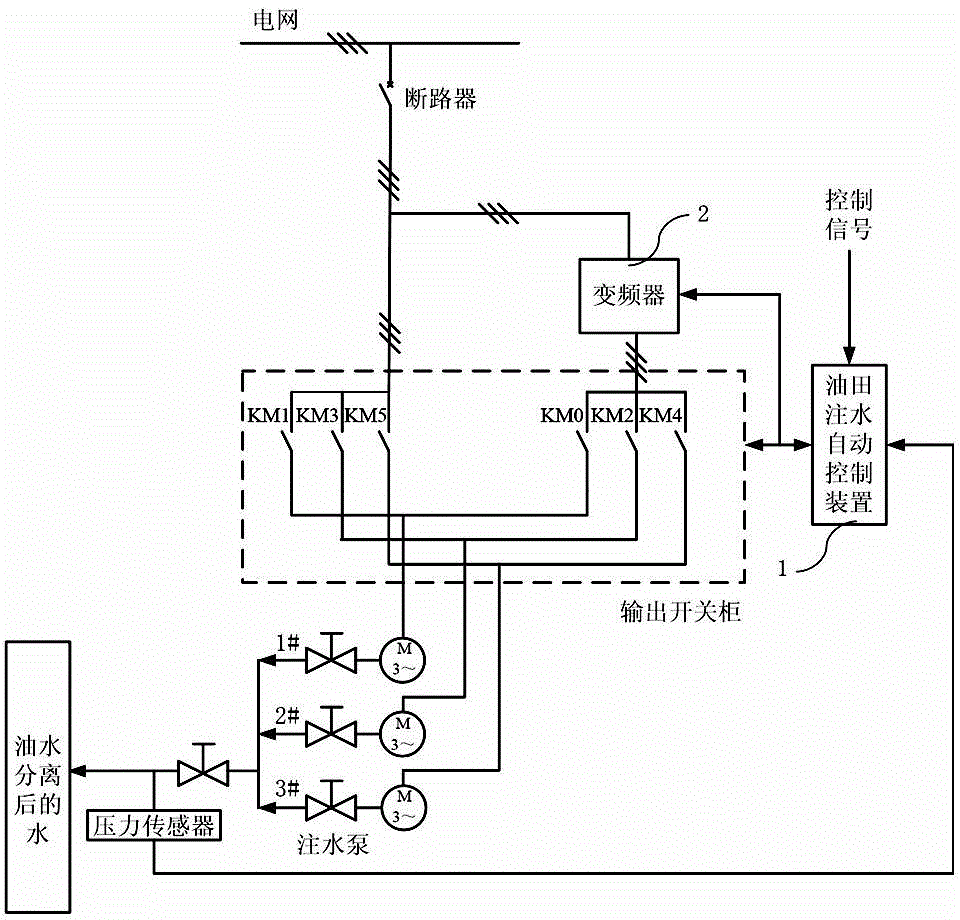

Method used

Image

Examples

Embodiment Construction

[0036] For the sake of reference and clarity, the technical terms, abbreviations or abbreviations used below are recorded as follows:

[0037]PLC: ProgrammableLogicController, the abbreviation of programmable logic controller, which uses a type of programmable memory for its internal storage program, executes user-oriented instructions such as logical operations, sequence control, timing, counting and arithmetic operations, and passes digital or analog input / output to control various types of machinery or production processes;

[0038] PID: ProportionIntegrationDifferentiation, the abbreviation of proportional integral differential control;

[0039] CPU: CentralProcessingUnit, the abbreviation of central processing unit;

[0040] A / D: Analog / Digital, short for analog / digital;

[0041] DI / DO: DigitalInput / DigitalOutput, the abbreviation of digital input / output.

[0042] In order to make the purpose, technical solutions and advantages of the embodiments of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com