Large-aperture laser frequency doubling conversion and focusing device with crystal temperature control function

A frequency doubling conversion and focusing device technology, applied in the direction of lasers, laser components, laser components, etc., can solve the problems of inability to achieve non-critical phase matching, lack of temperature control capabilities, etc., achieve high thermal conductivity, convenient operation, The effect of temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

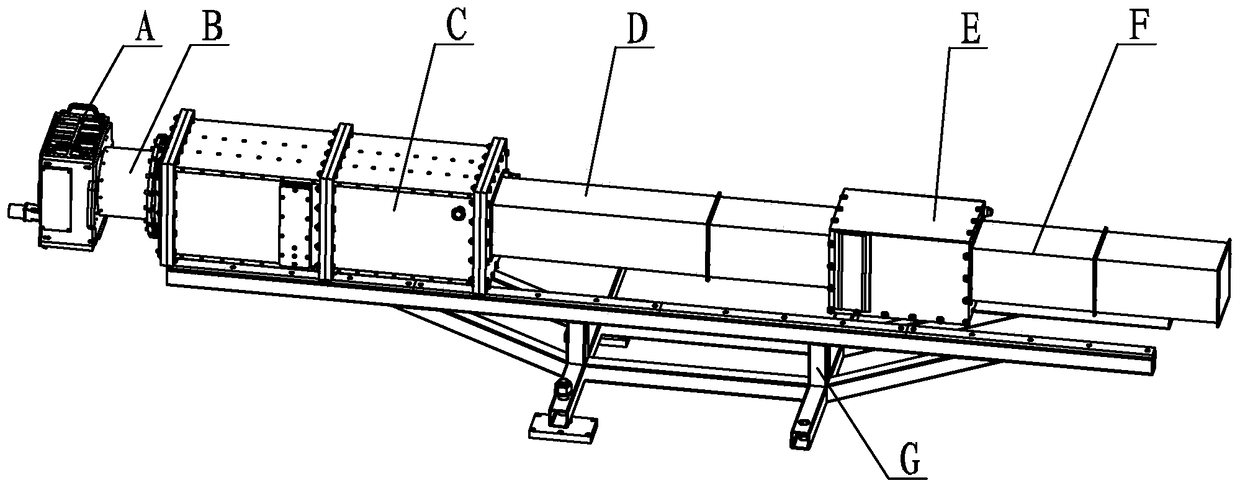

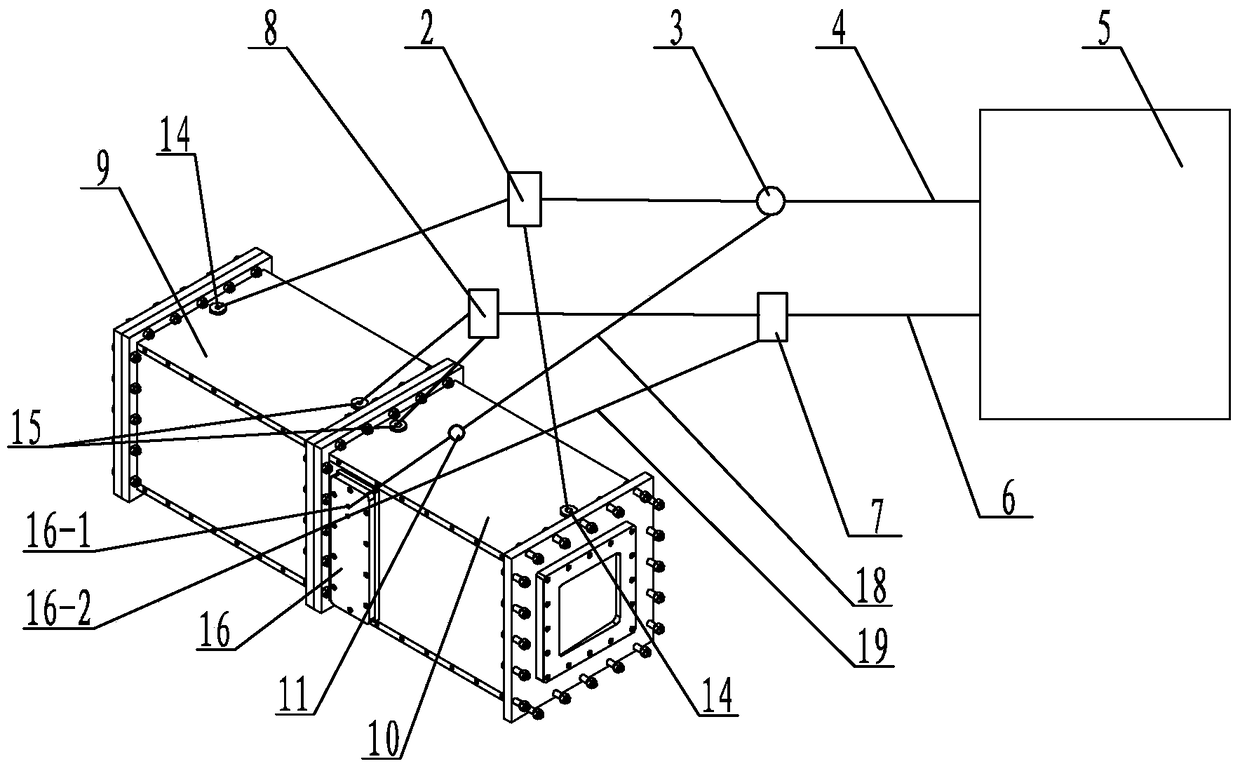

[0030] Specific implementation mode one: combine Figure 1 to Figure 14 Describe this embodiment, this embodiment includes focusing lens A, adapter flange B, quadruple frequency conversion module C, first light pipe D, double frequency conversion module E, second light pipe F and bracket G,

[0031] Focusing lens A, adapter flange B, quadruple frequency conversion module C, first light pipe D, double frequency conversion module E and second light pipe F are arranged in sequence from left to right, and focusing lens A and the transfer method The blue B is fixedly connected through the connection element, the adapter flange B is fixedly connected with the quadruple frequency conversion module C through the connection element, the quadruple frequency conversion module C is fixedly connected with the first light pipe D through the connection element, and the first light pipe D and the The double frequency conversion module E is fixedly connected through the connecting element, the...

specific Embodiment approach 2

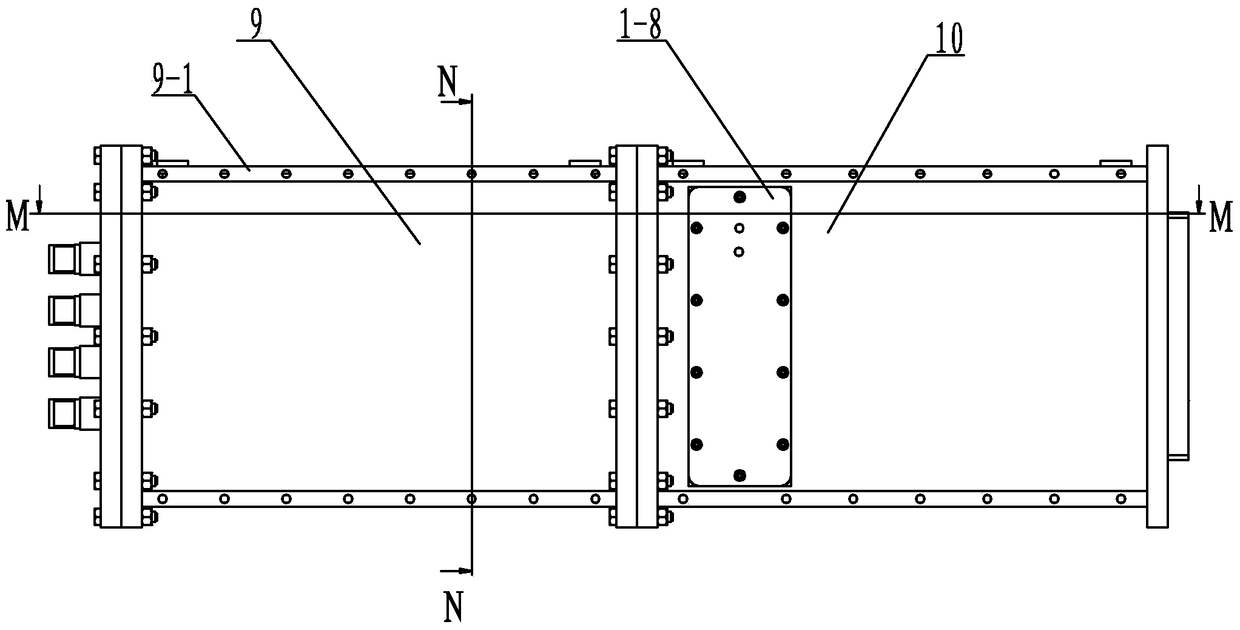

[0039] Specific implementation mode two: combination Figure 3 ~ Figure 6 To illustrate this embodiment, the first aluminum alloy rectangular frame body 9 of this embodiment is composed of an upper plate 9-1, a lower plate 9-2 and two side plates 9-3 to form a four-cavity rectangular frame body, and the upper plate 9-1 Set up and down with the lower plate 9-2, two side plates 9-3 are set on both sides of the upper plate 9-1 and the lower plate 9-2, and several lower shunt holes 9-2-1 are arranged on the lower plate 9-2 , the side plate 9-3 is provided with several side distribution holes 9-3-1, the several lower distribution holes 9-2-1 correspond to and communicate with the several side distribution holes 9-3-1,

[0040] The upper plate 9-1 is composed of the first upper plate 9-1-1 and the second upper plate 9-1-2, and the lower end surface of the first upper plate 9-1-1 is provided with a main water inlet channel 9-1-1 -1. Main water outlet channel 9-1-1-2, several water i...

specific Embodiment approach 3

[0041] Specific implementation mode three: combination Image 6 To describe this embodiment, the cross-sections of the main water inlet channel 9-1-1-1 and the main water outlet channel 9-1-1-2 in this embodiment along the length direction are all variable sections. Both the main water inlet flow channel 9-1-1-1 and the main water outlet flow channel 9-1-1-2 are triangular flow channels. Such setting can ensure that the water volume of each circulating water channel is the same, the temperature of the tank wall is uniform, and it is convenient to ensure that the pressure of the incoming water is more uniform and the return water is smoother. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com