Titanium metal osseointegration implant and titanium metal osseointegration implant surface treatment method

A surface treatment and implant technology, applied in the field of titanium metal osseointegration implant surface treatment, titanium metal osseointegration implant field, can solve problems such as unfavorable osseointegration, irregular cracks, infiltration, etc., to reduce infection risk, improve cleanliness, and improve the effect of bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

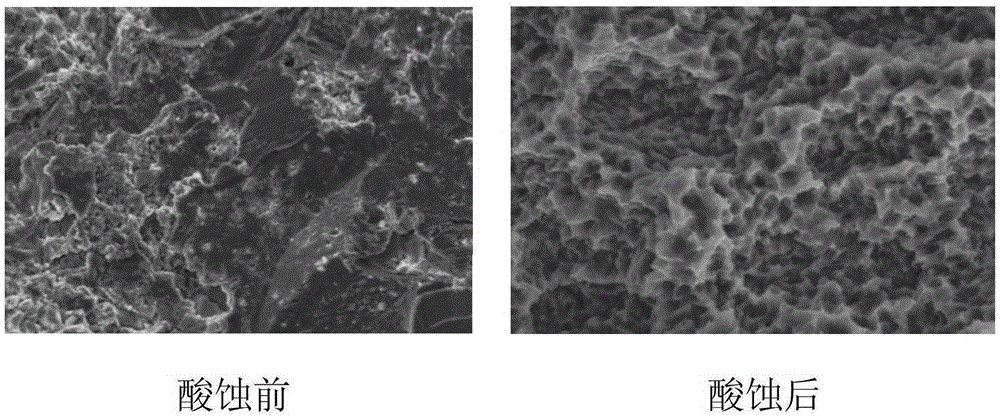

[0060] Form a roughened joint surface with unevenness on the surface of the implant by sandblasting;

[0061] Put the implant in the hydrochloric acid solution for 5-30 minutes, then take it out and wash it with distilled water or deionized water.

Embodiment 2

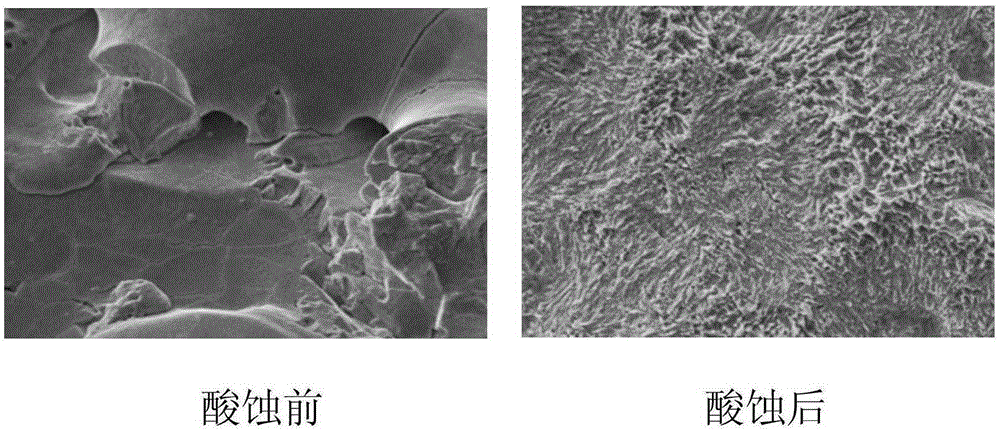

[0063] Form a roughened joint surface with unevenness on the surface of the implant through the shot peening process;

[0064] Place the implant in a mixed solution of hydrochloric acid and sulfuric acid for 5-30 minutes, and then take it out and clean it with distilled water or deionized water.

Embodiment 3

[0066] Form a roughened joint surface with unevenness on the surface of the implant by plasma titanium spraying process;

[0067] Place the implant in the nitric acid solution for 5-30 minutes, then take it out and clean it with distilled or deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com