Movable-type biomass collection and granulation system

A biomass and mobile technology, applied in the direction of die extrusion granulation, etc., can solve the problems of high transportation cost of biomass raw materials, large area of granulation equipment, reduction of labor costs, etc., and solve the problems of transportation and storage costs. , the effect of reducing labor input and solving the problem of floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

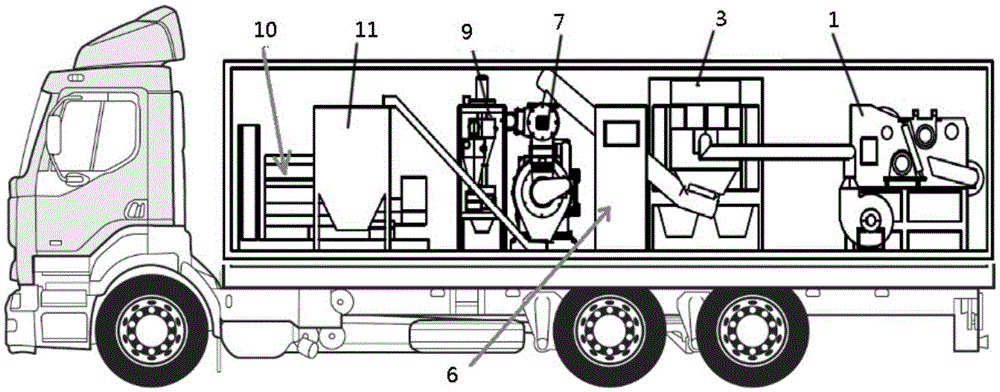

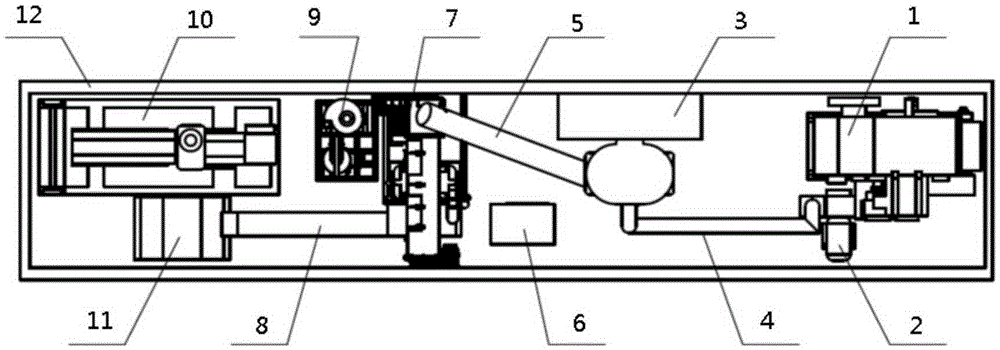

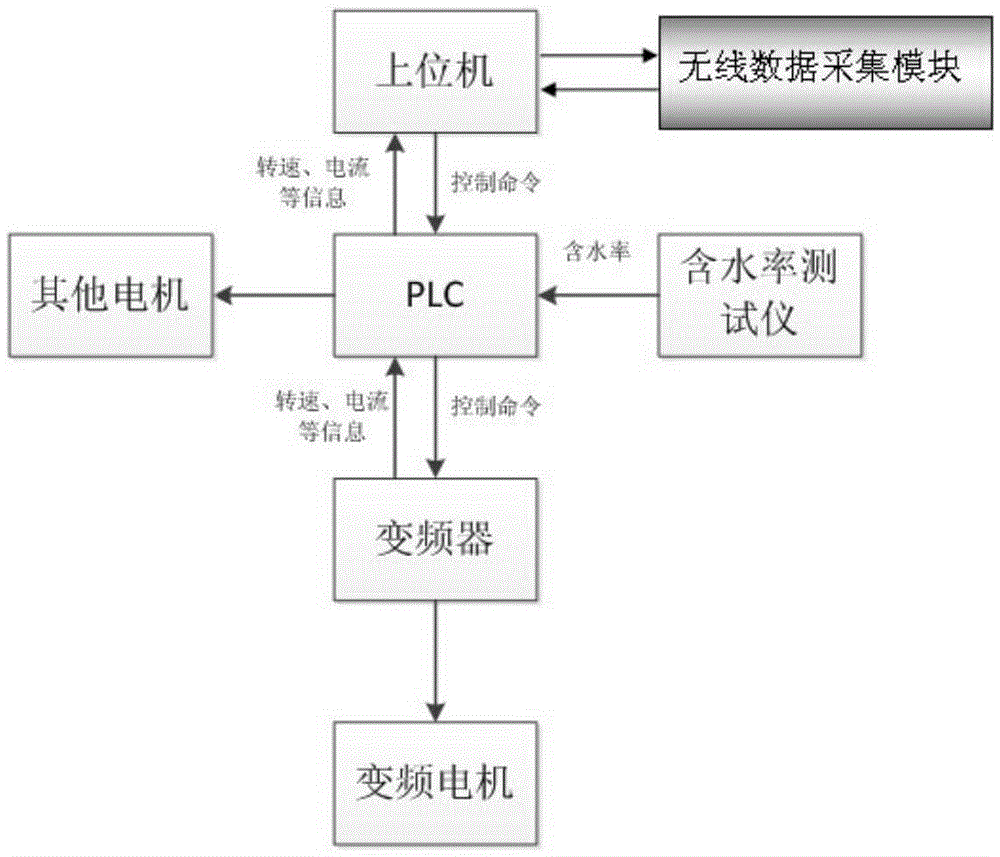

[0031] Such as figure 1 , 2 As shown, in the mobile biomass collection and granulation system provided by the present invention, the whole granulation system is installed in the mobile platform (container or box truck 12). The granulation system is equipped with a powder cutter 1, a dust collector 3, a feeding cage 5, a ring die granulator 7 (equipped with a main engine cooling device 9, that is, a heat dissipation device) connected in sequence, and a generator set 10 (for The whole granulation system provides power) and detection control system. The outlet of the ring die granulator is connected to a finished product bin 11 through a granule conveyor 8 . The detection control system includes a host computer, a PLC automatic control system 6 connected to the host computer through a PROFIBUS bus, a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com