Carbon dioxide methanation catalyst (Ni/CexZr(1-x)O2) and preparation method thereof

A methanation catalyst and carbon dioxide technology, applied in the field of catalyst preparation, can solve the problems of high cost of catalyst raw materials, complicated preparation methods, low catalytic activity, etc., and achieve the effects of low cost, simple preparation method, high catalytic activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] a. Weigh Ce(NO 3 ) 3 ·6H 2 O3.91g, Zr(NO 3 ) 4 ·5H 2 O0.43g, Ni(NO 3 ) 2 ·6H 2 O5.63g, add 50ml of deionized water, stir until dissolved and prepare a mixed solution.

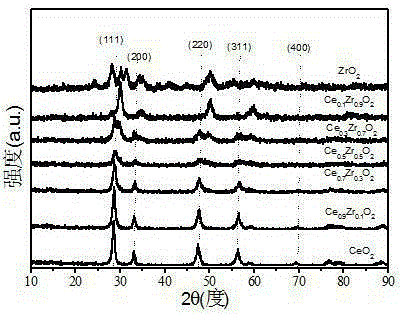

[0023] b. Move the solution to an 80°C water bath, stir continuously, pour 100ml of the prepared 2mol / L ammonium carbonate solution into the above-mentioned mixed solution quickly, continue stirring until it evaporates to dryness, transfer it to a muffle furnace for roasting, and heat it from room temperature at 2°C / L Min heating rate rose to 500 ℃ roasting 5h. , carrier Ce 0.9 Zr 0.1 o 2 The X-ray diffraction pattern of figure 1 As shown in the figure, the oxides of cerium and zirconium form a solid solution Ce 0.9 Zr 0.1 o 2 ..

[0024] c. Put the calcined powder at 25~35kN / Cm 2 It is extruded in a steel mold under a certain pressure; then crushed and sieved to obtain particles with a particle size of 40-60 mesh.

[0025] d. The obtained particles were washed with H at a flow rate ...

Embodiment 2

[0036] a. Weigh Ce(NO 3 ) 3 ·6H 2 O2.17g, Zr(NO 3 ) 4 ·5H 2 O2.15g, Ni(NO 3 ) 2 ·6H 2 Add 50ml of deionized water to O4.98g, stir until dissolved, and prepare a mixed solution.

[0037] b. Move the prepared solution to a water bath at 80°C, stir continuously, quickly pour 100ml of 2mol / L ammonium carbonate solution into the above mixed solution, continue stirring until evaporated to dryness, transfer to a muffle furnace for roasting, from room temperature to 2°C / min heating rate increased to 500 ℃ roasting 5h to obtain powder, carrier Ce 0.5 Zr 0.5 o 2 The X-ray diffraction pattern of figure 1 As shown in the figure, the oxides of cerium and zirconium form a solid solution Ce 0.5 Zr 0.5 o 2 ..

[0038] c. Put the roasted powder at 25~35kN / Cm 2 It is extruded in a steel mold under a certain pressure; then crushed and sieved to obtain particles with a particle size of 40-60 mesh.

[0039] d. The obtained particles were washed with H at a flow rate of 30ml / mi...

Embodiment 3

[0042] a. Weigh Ce(NO 3 ) 3 ·6H 2 O3.91g, Zr(NO 3 ) 4 ·5H 2 O0.43g, 3.51gNi(NO 3 ) 2 ·6H 2 Add 50ml of deionized water to O, and stir until dissolved to form a mixed solution.

[0043] b. Move the solution to an 80°C water bath, stir continuously, quickly pour 100ml of 2mol / L ammonium carbonate solution into the above mixed solution, continue stirring until it is evaporated to dryness, transfer to a muffle furnace for roasting, and start from room temperature at a temperature of 2°C / min. The heating rate was increased to 500 ° C for 5 h, and the carrier Ce 0.9 Zr 0.1 o 2 The X-ray diffraction pattern of figure 1 As shown in the figure, the oxides of cerium and zirconium form a solid solution Ce 0.9 Zr 0.1 o 2 .

[0044] c. Put the calcined powder at 25~35kN / Cm 2 It is extruded in a steel mold under a certain pressure; then crushed and sieved to obtain particles with a particle size of 40-60 mesh.

[0045] d. The obtained particles were washed with H at a fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com