Palladium catalyst for hydrogenation reaction of 1, 4-butylene glycol and preparation process thereof

A hydrogenation reaction, palladium catalyst technology, applied in catalyst activation/preparation, hydrogenation preparation, catalyst carrier and other directions, can solve the problems of poisoning, inability to adsorb active metals, high cost of precious metals, and achieve strong dissociative hydrogen absorption capacity, excellent The effect of catalytic hydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

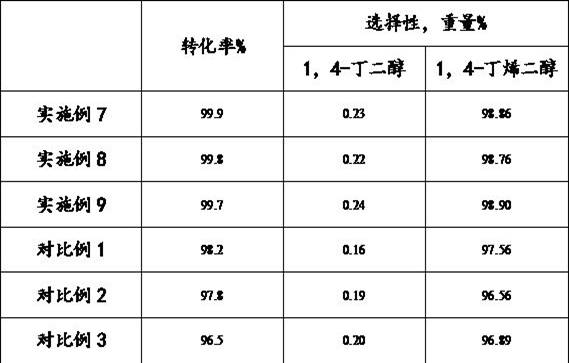

Examples

Embodiment 1

[0029] To prepare the modified carrier:

[0030] Step S1, respectively weigh 0.012mol magnesium chloride hexahydrate and 0.007mol aluminum chloride hexahydrate, mix and dissolve in 50mL deionized water, denoted as solution a, respectively weigh 0.033mol sodium hydroxide and 0.017mol sodium carbonate, mix and dissolve in 50mL Deionized water, denoted as solution b, slowly add solution b dropwise to solution a under high-speed stirring, complete the dropwise addition after 30 min, react for 2.5 h, control the pH value of the reaction system to 9, and obtain a gel, which is subjected to Centrifugal washing to neutrality, adding distilled water to it, placing it in a hydrothermal crystallization kettle, crystallizing at 102 °C for 16 h, cooling and washing, drying at 80 °C, and pulverizing to obtain Intermediate 1;

[0031] Step S2, add 2.9mmol 2,3-pyridinedicarboxylic acid and 105mL deionized water to the flask, adjust the pH to 8 with sodium hydroxide solution, add 2.9mmol nicke...

Embodiment 2

[0035] To prepare the modified carrier:

[0036]Step S1, respectively weigh 0.013mol magnesium chloride hexahydrate and 0.008mol aluminum chloride hexahydrate, mix and dissolve in 52mL deionized water, denoted as solution a, respectively weigh 0.034mol sodium hydroxide and 0.018mol sodium carbonate, mix and dissolve in 53mL Deionized water, denoted as solution b, slowly add solution b dropwise to solution a under high-speed stirring, complete the dropwise addition after 30 min, react for 2.5 h, control the pH value of the reaction system to 10, and obtain a gel, which is subjected to Centrifugal washing to neutrality, adding distilled water to it, placing it in a hydrothermal crystallization kettle, crystallization at 104°C for 16 hours, cooling and washing, drying at 80°C, and pulverizing to obtain Intermediate 1;

[0037] Step S2, add 3mmol 2,3-pyridinedicarboxylic acid and 107mL deionized water to the flask, adjust pH to 8 with sodium hydroxide solution, add 3mmol nickel ni...

Embodiment 3

[0041] To prepare the modified carrier:

[0042] Step S1, respectively weigh 0.014mol magnesium chloride hexahydrate and 0.009mol aluminum chloride hexahydrate, mix and dissolve in 55mL deionized water, denoted as solution a, respectively weigh 0.035mol sodium hydroxide and 0.019mol sodium carbonate, mix and dissolve in 55mL Deionized water, denoted as solution b, slowly add solution b dropwise to solution a under high-speed stirring, complete the dropwise addition after 30 minutes, react for 3 hours, control the pH value of the reaction system to 11, obtain gel, and centrifuge the gel Washed to neutrality, added distilled water, placed in a hydrothermal crystallization kettle, crystallized at 105°C for 17h, cooled and washed, dried at 80°C, and pulverized to obtain Intermediate 1;

[0043] Step S2, add 3.1mmol 2,3-pyridinedicarboxylic acid and 110mL deionized water to the flask, adjust the pH to 8 with sodium hydroxide solution, add 3.1mmol nickel nitrate hexahydrate, stir ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com