A mixing mill

A milling machine and milling technology, applied in cocoa, grain processing, food science, etc., can solve the problems of low efficiency and single function, and achieve the effect of improving efficiency, simple operation, and good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

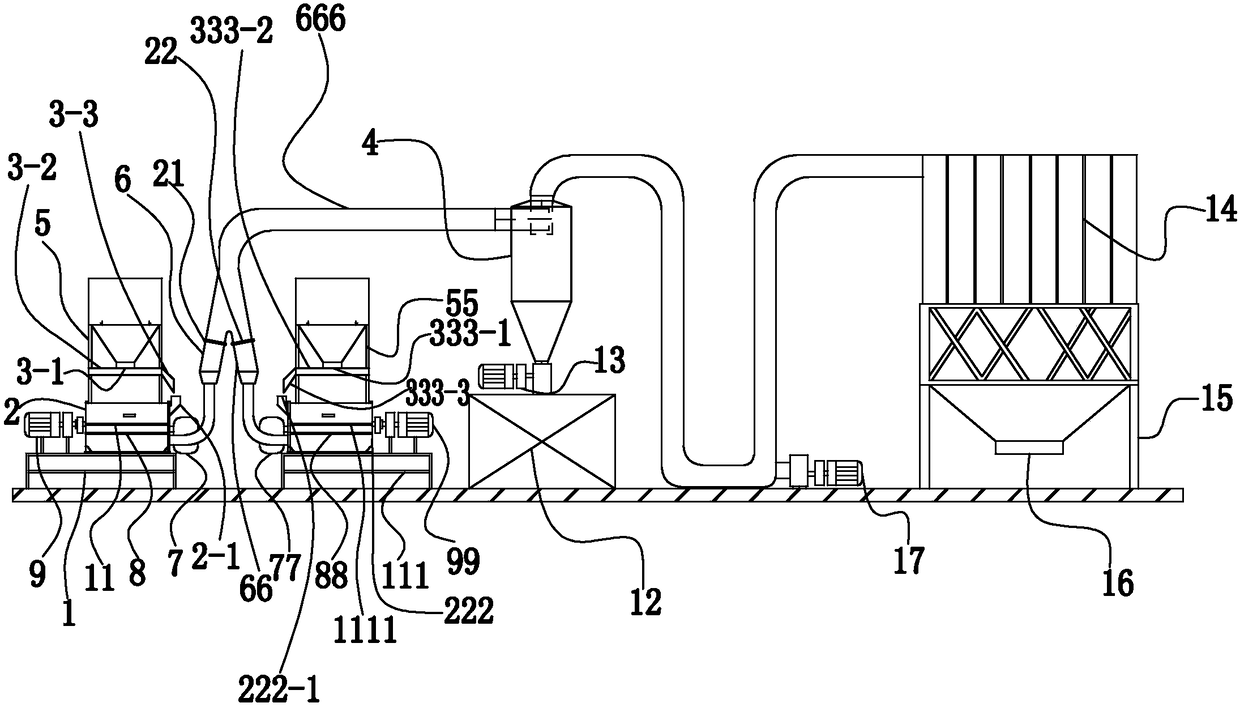

[0021] Embodiment one: if figure 1 Shown: a mill for mixed processing, including at least two sets of first mill processing device, second mill processing device, powder collector 4 and dust collector 14 arranged side by side; the first mill The processing device and the second milling machine processing device are arranged symmetrically on both sides, and the first milling machine processing device includes a first frame 1, a first milling device 2, and a first feeding device 3; The bottom end of the milling device 2 is fixed on the first frame 1. One side of the first milling device 2 is connected with the first air outlet pipe 6, and the other side is connected with the first rotating motor 9. The first rotating motor 9 is fixed on the first frame 1; the first milling device 2 is provided with a first moving mill 11 and a first filter 8; the first filter 8 is arranged on the inner side wall of the first milling device 2 , and away from the first movable millstone 11; the f...

Embodiment 2

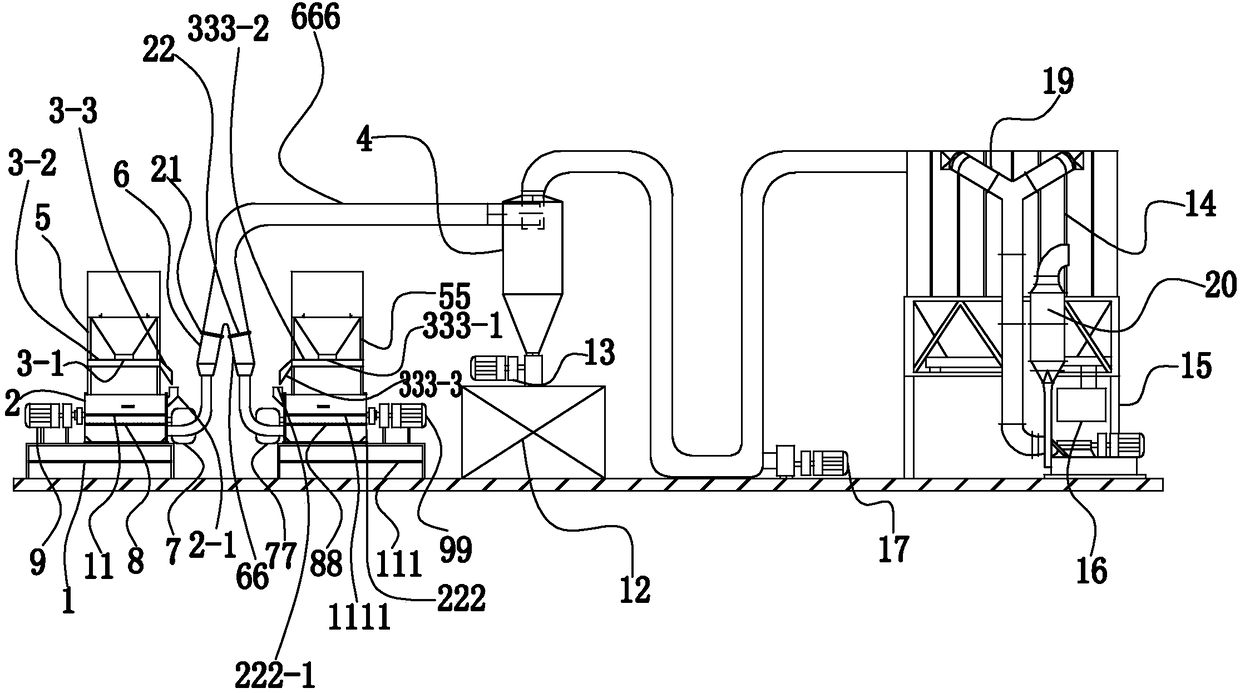

[0029] Embodiment two: if figure 2 As shown, in this embodiment, a high-pressure fan is provided outside the dust collector 14, and the high-pressure fan and the dust collector 14 are connected through an air duct 19 to form a sealed space. By adding a high-pressure fan outside the dust collector 14, the internal and external pressure of the mill body is balanced, thereby improving the stress environment of the mill body, and then making the mill body follow the design and production requirements of the general grade, greatly improving the performance of the mill body. Reduce the cost of research and development and manufacturing; at the same time, the internal pressure of the mill body is reduced through the operation of the high-pressure fan, so that the mill body is equivalent to negative pressure operation, thus reducing dust leakage and dust, reducing environmental dust pollution; and, by being provided with the muffler 20 for noise elimination on the side of the dust co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com