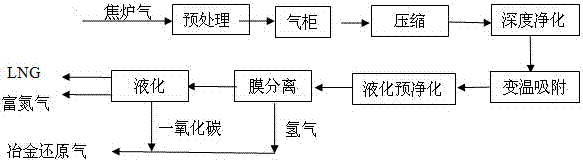

A process for producing metallurgical reduction gas and co-production of liquefied natural gas by using coke oven gas

A technology for liquefied natural gas and coke oven gas, which is applied in refrigeration and liquefaction, liquefaction, carbon monoxide, etc., to achieve the effects of stable operation, high reliability, and high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of technology that utilizes coke oven gas to produce metallurgical reduction gas to co-produce LNG, the concrete steps of described technology are as follows:

[0039] (1) Pre-purification

[0040] Coke oven gas flow rate is 32000Nm 3 / h, where, in terms of volume percentage, H 2 content of 57.2%, CO content of 6.8%, CH 4 The content is 24%, CO 2 The content is 2.6%, N 2 content of 5%, polycarbonate content of 3.6%, O 2 The content is 0.8%. Impurity content: benzene, toluene content about 3500mg / Nm 3 , the naphthalene content is about 200mg / Nm 3 , tar and dust content about 100mg / Nm 3 , the ammonia content is about 45mg / Nm 3 , H 2 S content about 200mg / Nm 3 , the organic sulfur content is about 250mg / Nm 3 , the ratio of the total volume percentage is 100%. The raw coke oven gas of this composition enters the pre-purification device at a temperature of 40°C and a pressure of 7kPa, and uses the adsorption of coke to reduce the tar content to 4mg / Nm 3 ...

Embodiment 2

[0056] A kind of technology that utilizes coke oven gas to produce metallurgical reduction gas co-production LNG, same as embodiment 1, wherein:

[0057] In step (1), the coke oven gas flow rate is 42000Nm 3 / h, where, in terms of volume percentage, H 2 content of 57.1%, CO content of 7%, CH 4 The content is 24%, CO 2 The content is 2.5%, N 2 content of 5%, polycarbonate content of 3.9%, O 2 The content is 0.5%. Impurity content: benzene, toluene content about 4000mg / Nm 3 , the naphthalene content is about 200mg / Nm 3 , tar and dust content about 120mg / Nm 3 , the ammonia content is about 48mg / Nm 3 , H 2 S content about 200mg / Nm 3 , the organic sulfur content is about 300mg / Nm 3 , the ratio of the total volume percentage is 100%. The raw coke oven gas of this composition has a temperature of 40°C and a pressure of 7kPa, and enters the pre-purification device, and uses the adsorption of coke to reduce the tar content to 4mg / Nm 3 Below, naphthalene content is reduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com