Disc multi-stage composite biological purification integrated process

A biological purification, disc-type technology, applied in water/sewage multi-stage treatment, animal processing wastewater treatment, chemical instruments and methods, etc., can solve the problems of low efficiency and high requirements for phosphorus removal, and achieve high operating efficiency and treatment effect. Good, high microbial concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

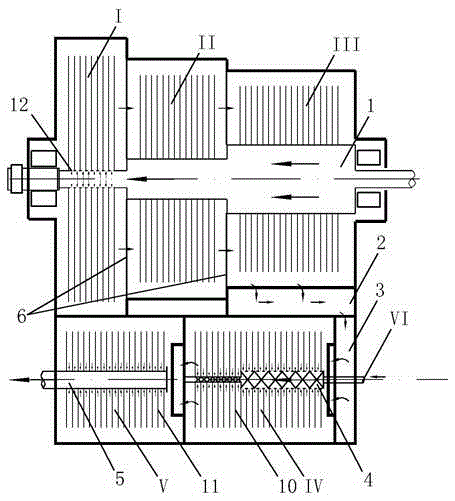

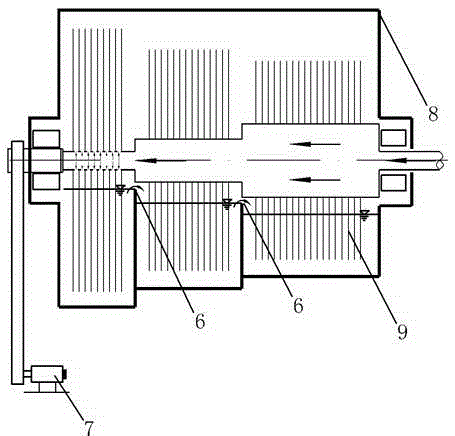

[0029] Raw water passes through I. first-level anoxic disc module; II. second-level anoxic disc module; III. third-level aerobic disc module; IV. coarse filter mud-water separation module; V. fine filter phosphorus removal biochemical module; When there is a requirement for phosphorus removal, the VI. will add phosphorus removal agent system for phosphorus removal.

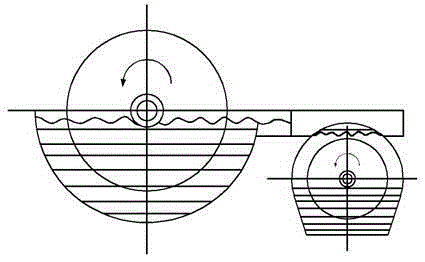

[0030] Raw water first enters the three-stage tapered pipeline 1, and the diameter of the water flow decreases after entering the pipeline, and the flow rate increases. When it enters the first-level disk anoxic module I, the water flow passes through the water diversion hole 12 designed on the pipeline when the pipeline shaft rotates. Spray onto the bio-disc 9 to increase the contact effect.

[0031] According to the proportion of the contact part between the disk and water, the speed and the water flow process, it is divided into 3 levels, respectively I. The first-level disk anoxic module; II. The second-level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com