Coal chemical industrial wastewater treatment system and treatment process

A coal chemical wastewater and treatment system technology, applied in multi-stage water treatment, flotation water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as low treatment efficiency and complicated process flow, and achieve simplified process flow , Reduce the cost of use, and the effect of reasonable pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment provides a coal chemical wastewater treatment system, including a raw water tank, an anaerobic tank, an aerobic tank and a membrane tank connected in sequence. And film tank, aeration device is installed in the aerobic tank, and an active coke dosing system is installed on the upper part of the anaerobic tank. 0.5g / ml~0.6g / ml activated coke, a return circulation pipeline is set between the lower part of the membrane tank and the anaerobic tank, and the sludge generated at the membrane tank is returned to the anaerobic tank through the return pipeline.

[0058] In this embodiment, a pretreatment unit is provided between the raw water tank and the anaerobic tank. Optionally, the pretreatment unit further includes a grease trap and an air flotation tank, and the coal chemical wastewater is firstly treated in the grease trap and the air flotation tank. , in the present embodiment, the grease trap is preferably a sloping plate type grease trap; as a convertib...

Embodiment 2

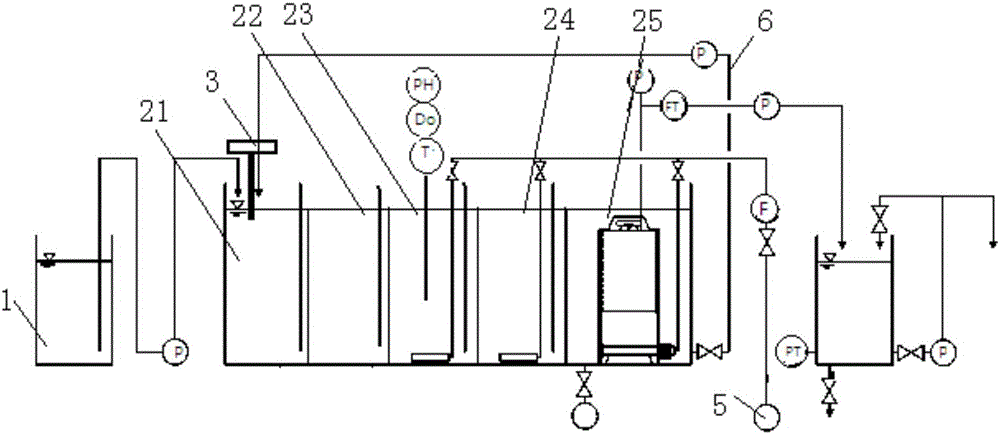

[0081] This embodiment provides a coal chemical industry wastewater treatment system, such as Image 6 As shown, the raw water tank 1, the anaerobic tank 21, the aerobic tank and the membrane tank 25 are sequentially connected. , an aeration device is provided in the aerobic tank, and an active coke dosing system 3 is provided on the upper part of the anaerobic tank 21. The activated coke is 0.5g / ml~0.6g / ml, and the backflow circulation pipeline 6 is set between the lower part of the membrane tank 25 and the anaerobic tank 21, and the sludge generated at the membrane tank 25 is returned to the anaerobic tank through the backflow circulation pipeline 6. oxygen tank.

[0082] As an embodiment of the present invention, in this embodiment, the aerobic tank includes a primary aerobic tank 23 and a secondary aerobic tank 24, and the treatment in the two-stage aerobic tank can enhance the sewage treatment capacity.

[0083] In the present embodiment, between the anaerobic tank 21 a...

Embodiment 3

[0092]This embodiment provides a coal chemical wastewater treatment system, including a raw water tank, an anaerobic tank, an aerobic tank and a membrane tank connected in sequence. And film tank, aeration device is installed in the aerobic tank, and an active coke dosing system is installed on the upper part of the anaerobic tank. 0.5g / ml-0.6g / ml activated coke, a sludge return pipeline is set between the lower part of the membrane tank and the anaerobic tank, and the sludge generated at the membrane tank is returned to the anaerobic tank through the return circulation pipeline.

[0093] In this example, activated coke and excess sludge are discharged from the membrane tank and enter the dehydration mixed charcoal burning device.

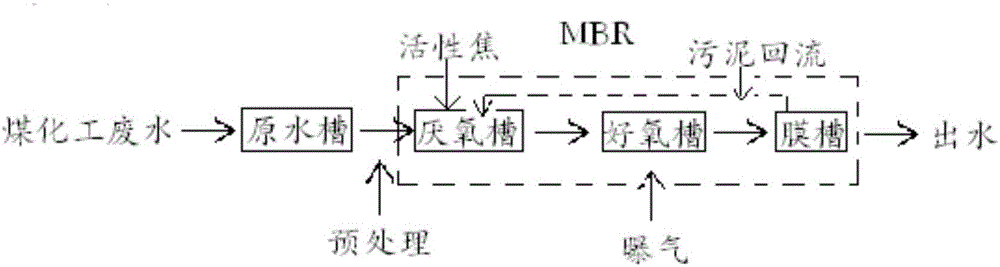

[0094] This embodiment also provides a wastewater treatment process based on the above system, such as Figure 4 shown, including the following steps:

[0095] S1. Send the coal chemical industry wastewater from the raw water tank to the anaerobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com