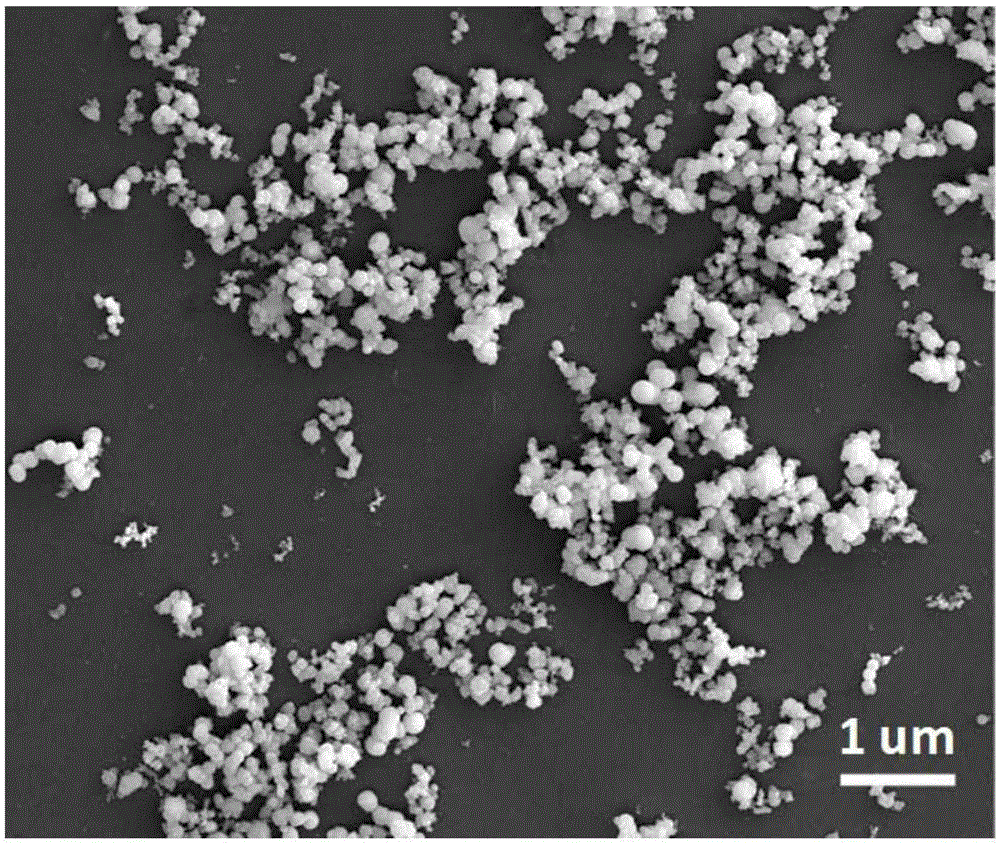

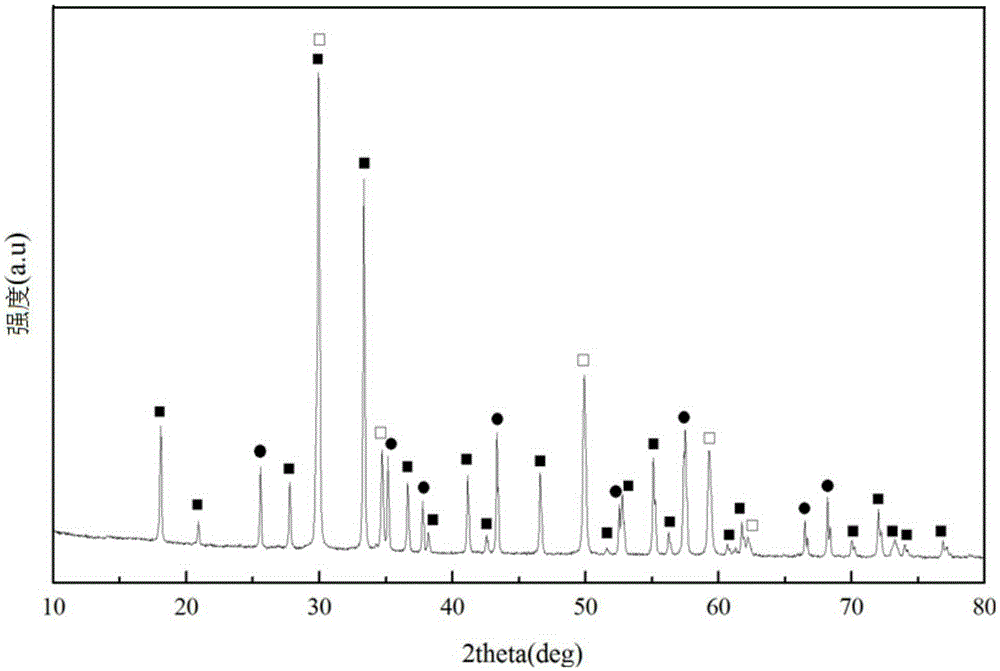

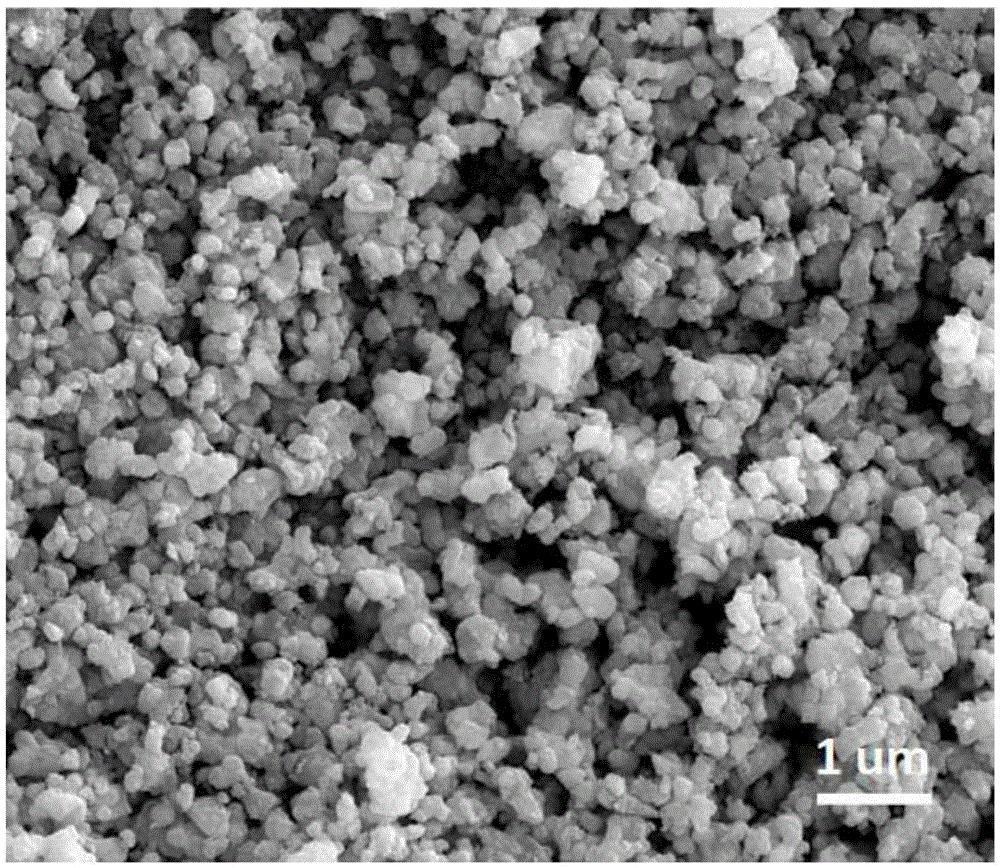

Preparation method of nano Al2O3/Y3Al5O12/ZrO2 composite powder materials

A y3al5o12, composite powder technology, which is applied in the field of preparation of nano-Al2O3/Y3Al5O12/ZrO2 composite powder materials, can solve the problems of uniform dispersion, particle size and other properties, complex preparation process, and difficult particles of each phase, etc., and achieve technical cost Low cost, simple synthesis process, and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment one: this embodiment is a kind of nano-Al 2 o 3 / Y 3 Al 5 o 12 / ZrO 2 The preparation method of composite powder material is specifically carried out according to the following steps:

[0021] 1. Prepare raw material solution: ZrOCl2 ·8H 2 O is dissolved in the alcoholic aqueous solution I to obtain ZrOCl with a concentration of 0.1mol / L~1mol / L 2 ·8H 2 O alcohol aqueous solution; Al(NO 3 ) 3 9H 2 O or Al 2 (SO 4 ) 3 18H 2 O is dissolved in the alcoholic aqueous solution II to obtain an aluminum salt alcoholic aqueous solution with a concentration of 0.1mol / L to 1mol / L; Y 2 o 3 The powder is dissolved in concentrated nitric acid, and dissolved in an oven at 50°C to 120°C until a clear yttrium nitrate solution is obtained. The concentration of the yttrium nitrate solution is 0.1mol / L to 5mol / L; the alcoholic aqueous solution I is composed of alcohols I is mixed with deionized water, and the volume ratio of deionized water and alcohols I...

specific Embodiment approach 2

[0026] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the alcohols I described in step one is isopropanol, methyl alcohol, absolute ethanol or n-butanol; the alcohols described in step one II is isopropanol, methanol, absolute ethanol or n-butanol. Others are the same as the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass fraction of the concentrated nitric acid in step 1 is 65%-68%. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com