Automobile instrument panel protective plate and preparation method thereof

An automobile dashboard and content technology, which is applied in the field of auto parts, can solve problems such as high impact toughness, and achieve the effects of high impact toughness, simple steps and good high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The present invention provides a kind of preparation method of automobile instrument panel protection plate, wherein, described preparation method comprises:

[0013] (1) Mix isocyanate compound, polyether polyol, water, foam stabilizer, tertiary amine compound and stannous octoate uniformly to prepare mixture M1;

[0014] (2) The mixture M1 is mechanically formed to obtain an automobile instrument panel guard, wherein,

[0015] Relative to 100 parts by weight of isocyanate compounds, the content of polyether polyol is 40-65 parts by weight, the content of water is 1-10 parts by weight, the content of foam stabilizer is 0.2-1.5 parts by weight, tertiary amine The content of the compound is 0.1-0.5 parts by weight, and the content of stannous octoate is 0.1-0.3 parts by weight.

[0016] The present invention is by uniformly mixing isocyanate compounds, polyether polyols, water, foam stabilizers, tertiary amine compounds and stannous octoate, and performing mechanical mo...

Embodiment 1

[0026] Mix toluene diisocyanate, polyether polyol with a weight average molecular weight of 800, water, polyvinyl alcohol, triethylamine and stannous octoate in a weight ratio of 100:50:3:0.5:0.3:0.15 to prepare The mixture M1 was obtained; after the mixture M1 was heated to 120°C, it was cast into a casting mold for solidification and water cooling, wherein the pressure in the casting mold was 20 MPa, and the solidification time was 5 minutes. During cooling, the cooling temperature was 20°C, and the cooling The time is 15 minutes, and finally the automobile instrument panel shield A1 is obtained.

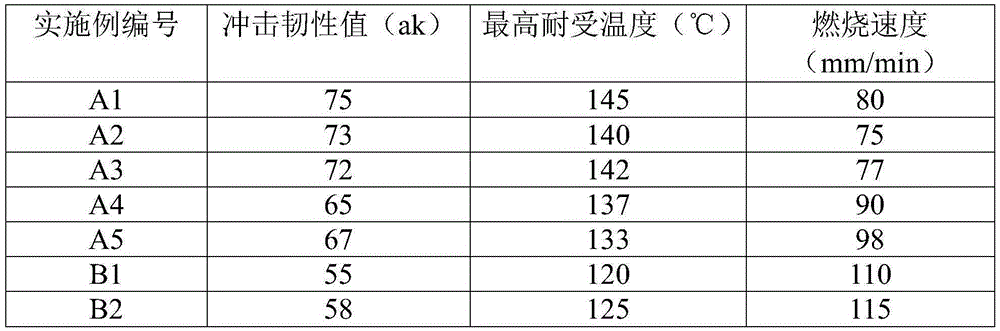

[0027] The impact toughness, high temperature resistance and flame retardancy of A1 were tested, and the test results are shown in Table 1.

Embodiment 2

[0029] Diphenylmethane diisocyanate, polyether polyol with a weight-average molecular weight of 2000, water, alkanolamide, triethylenediamine and stannous octoate in a weight ratio of 100:60:7:1:0.4:0.25 The ratio is mixed evenly to prepare the mixture M1; after the mixture M1 is heated to 170°C, it is cast into a casting mold to solidify and water-cooled, wherein the pressure in the casting mold is 25MPa, and the solidification time is 8min. During cooling, the cooling temperature is 25°C, and the cooling time is 25 minutes, and the automobile instrument panel protective panel A2 is finally prepared.

[0030] The impact toughness, high temperature resistance and flame retardancy of A2 were tested, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com