Bamboo fiber-reinforced material and preparation method therefor

A reinforcement material and bamboo fiber technology, applied in the field of composite materials, can solve the problems of bamboo fiber being easily corroded and degraded by bacteria, low antibacterial efficiency, and waste of resources, so as to improve the sterilization ability and effective sterilization time, reduce raw material cost, mechanical The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

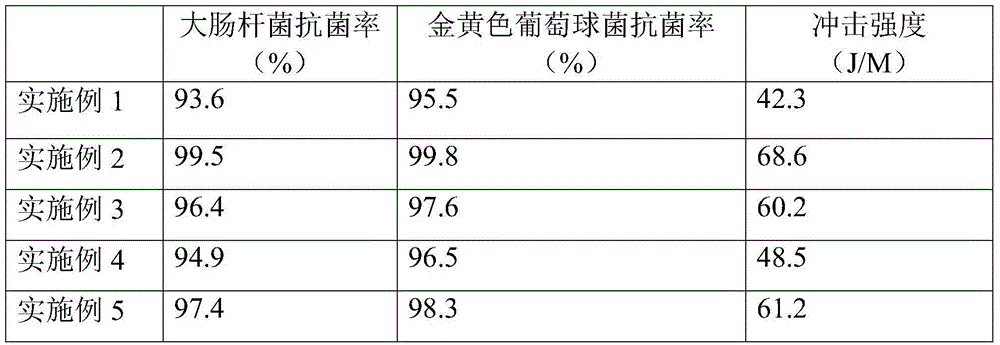

Embodiment 1

[0038] A kind of bamboo fiber reinforced material is prepared according to the following method:

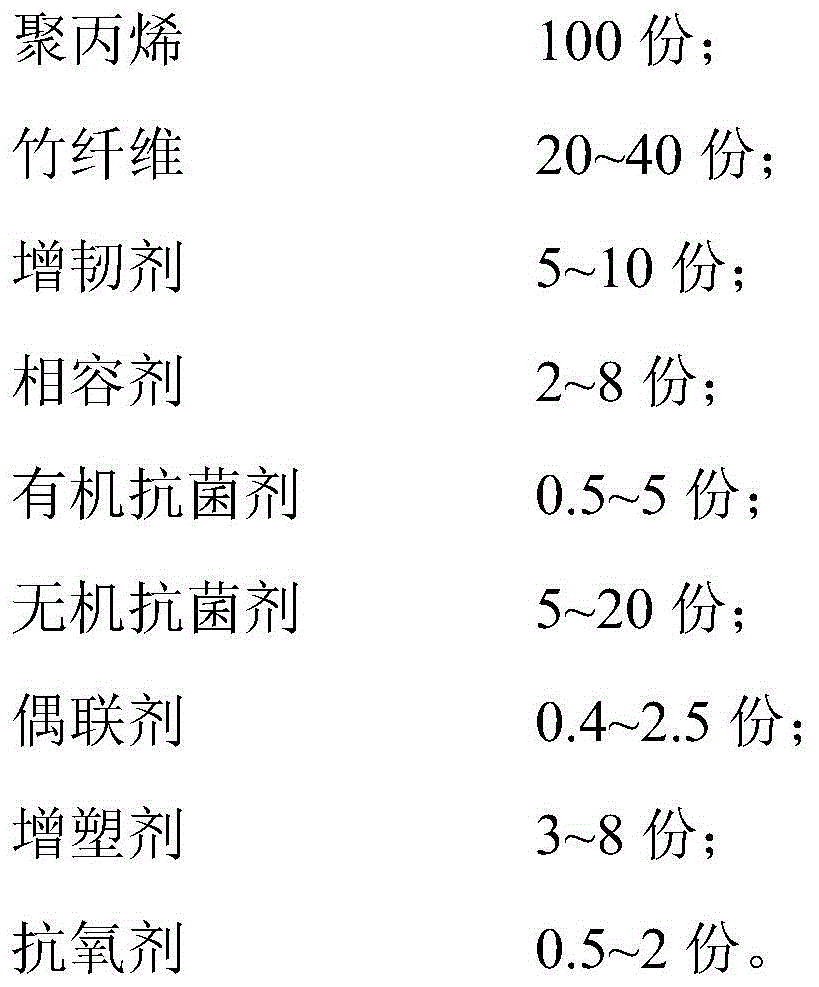

[0039] (1) 100 parts of polypropylene are weighed by weight; 20 parts of bamboo fiber; 5 parts of toughening agent; 2 parts of compatibilizer; 0.5 part of organic antibacterial agent; 5 parts of inorganic antibacterial agent; 0.4 part of coupling agent; 3 parts of anti-oxidant; 0.5 part of antioxidant;

[0040] Wherein, described bamboo fiber is made by following method: first cut bamboo along the growth direction of bamboo into elongated bamboo slices, then use press machine to roll bamboo slices, and grind along the transverse direction of bamboo fibers, make bamboo fibers unfold Evenly dispersed, dried and screened through a sieve to obtain the bamboo fiber;

[0041] The prepared bamboo fiber has a diameter of 200um to 500um, an aspect ratio of 1: (10 to 50), has been dried before use, and has a moisture content of less than 0.05%.

[0042] The toughening agent is ethylene-p...

Embodiment 2

[0047] A kind of bamboo fiber reinforced material is prepared according to the following method:

[0048] (1) 100 parts of polypropylene are weighed by weight; 40 parts of bamboo fiber; 10 parts of toughening agent; 8 parts of compatibilizer; 5 parts of organic antibacterial agent; 20 parts of inorganic antibacterial agent; 2.5 parts of coupling agent; 8 parts of anti-oxidant; 2 parts of antioxidant;

[0049] Wherein, described bamboo fiber is made by following method: first cut bamboo along the growth direction of bamboo into elongated bamboo slices, then use press machine to roll bamboo slices, and grind along the transverse direction of bamboo fibers, make bamboo fibers unfold Evenly dispersed, dried and screened through a sieve to obtain the bamboo fiber;

[0050] The prepared bamboo fiber has a diameter of 200um to 500um, an aspect ratio of 1:50 to 100, and has been dried before use, with a moisture content of less than 0.05%.

[0051] The toughening agent is EPDM rubbe...

Embodiment 3

[0056] A kind of bamboo fiber reinforced material is prepared according to the following method:

[0057] (1) 100 parts of polypropylene are weighed by weight; 30 parts of bamboo fiber; 8 parts of toughening agent; 5 parts of compatibilizer; 3 parts of organic antibacterial agent; 12 parts of inorganic antibacterial agent; 2.2 parts of coupling agent; 5 parts of anti-oxidant; 1.5 parts of antioxidant;

[0058] Wherein, described bamboo fiber is made by following method: first cut bamboo along the growth direction of bamboo into elongated bamboo slices, then use press machine to roll bamboo slices, and grind along the transverse direction of bamboo fibers, make bamboo fibers unfold Evenly dispersed, dried and screened through a sieve to obtain the bamboo fiber;

[0059] The prepared bamboo fiber has a diameter of 500um to 1000um and an aspect ratio of 1:50 to 100. It has been dried before use and has a moisture content of less than 0.05%.

[0060] The toughening agent is ethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com