Preparation method of quaternary quantum dot CdSe@ZnS

A quantum dot, cd-zn technology, applied in the field of preparation of quaternary quantum dots CdSeZnS, can solve the problems of difficulty in ensuring the quality of final quantum dots, repeatability, high price, complicated steps, etc., and achieves increased yield, enhanced stability, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

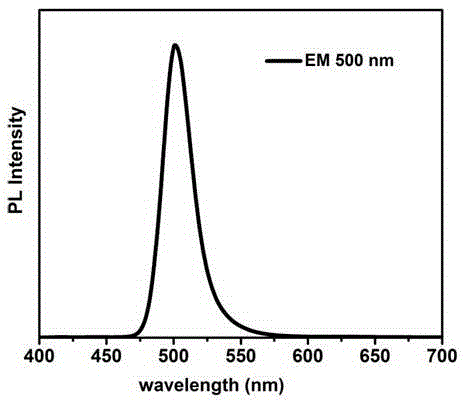

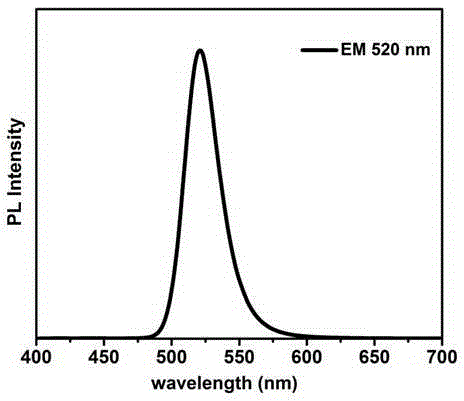

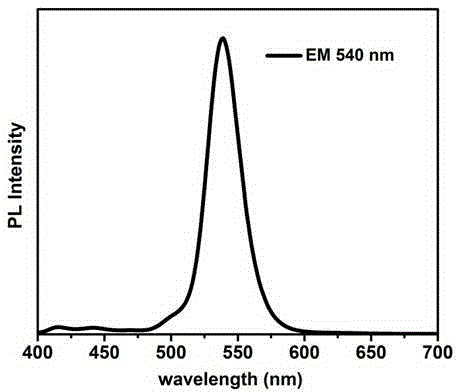

Image

Examples

preparation example Construction

[0030] The embodiment of the present invention provides a kind of preparation method of quaternary quantum dot CdSeZnS, comprising

[0031] Step 1. Dissolving the Cd source and Zn source in the mixed solution of long-chain fatty acids and long-chain alkenes, and then heating the mixed liquid to 140-300°C in a container filled with inert gas to obtain Cd-Zn front body stock solution; wherein the Cd source is cadmium acetate or an inorganic salt of cadmium; the Zn source is zinc acetate or zinc stearate or zinc oxide;

[0032] Step 2, dissolving Se source and S source in trihydrocarbyl phosphine to obtain Se and S precursor stock solution; in a container filled with inert gas, inject Se and S precursor stock solution into Cd-Zn precursor stock solution Fully mixed and stirred to fully react to obtain a CdSeZnS solution, so that the molar ratio of the Cd precursor, the Zn precursor and the Se precursor is 1:25:25-10;

[0033] Step 3, fully mix the mixed solution of Zn so...

Embodiment 1

[0049] (a) Weigh 0.8mmol cadmium acetate and 20.0mmol zinc stearate into four-neck bottle A, add 42ml oleic acid and 90ml octadecene (ODE), heat to 140°C to completely dissolve cadmium acetate and zinc acetate , to obtain the Zn-Cd precursor stock solution.

[0050] (b) Weigh 16mmol of zinc acetate into three-necked bottle B, add 12mL of oleic acid (OA) and 18ml of octadecene (ODE), and completely dissolve the zinc acetate under the protection of nitrogen to obtain a Zn precursor stock solution; Prepare the S source solution, that is, dodecyl mercaptan (DDT) 8mmol, tributylphosphine (TBP) 45mmol, ODE, 15ml. Mix well to obtain the precursor solution of the S source.

[0051] (c) Weigh 20mmol of Se powder and 20mmol of S into conical flask C, and add 46mmol of TBP so that the molar ratio of Se, S and TBP is 1:2.3, ultrasonically oscillate to completely dissolve Se and S, and obtain Se and S precursors. body stock solution. Under the protection of nitrogen, the temperatur...

Embodiment 2

[0056] (a) Weigh 0.8mmol cadmium acetate and 20.0mmol zinc stearate into four-neck bottle A, add 42ml oleic acid and 90ml octadecene (ODE), heat to 140°C to completely dissolve cadmium acetate and zinc acetate , to obtain the Zn-Cd precursor stock solution.

[0057] (b) Weigh 16mmol of zinc acetate into three-neck bottle B, add 12mLOA and 18ml of ODE, and completely dissolve zinc acetate under nitrogen protection to obtain Zn precursor stock solution; configure S source solution, namely DDT8mmol, TBP45mmol, ODE , 15ml. Mix well to get the precursor solution of S source.

[0058] (c) Weigh 16mmol of Se powder and 16mmol of S into Erlenmeyer flask C, add 36.8mmol of TBP, make the molar ratio of Se, S and TBP 1:1:2.3, and ultrasonically oscillate to completely dissolve Se and S to obtain Se , S precursor stock solution. Under the protection of nitrogen, the temperature of the Cd-Zn precursor stock solution was raised to 300°C, and the Se and S precursor stock solutions we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com