Comprehensive pre-treatment method of kitchen garbage and gutter oil

A technology of kitchen waste and gutter oil, which is applied in the direction of recycling fat oil/fatty acid from waste materials, recycling technology, fat generation, etc., can solve the problems of poor overall operation, insufficient estimation of raw material impurities, lack of experience, etc., to achieve realization Effects of harmlessness and resource utilization, reduction of residence time, and improvement of separation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

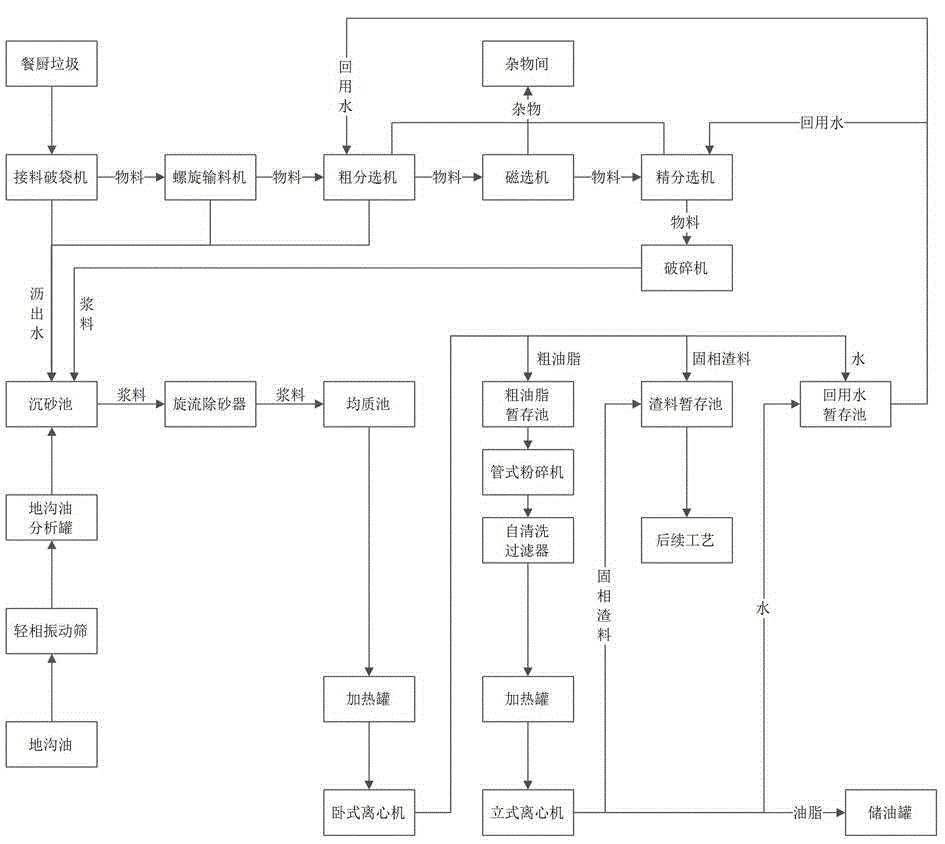

Image

Examples

Embodiment Construction

[0034] A comprehensive pretreatment method for food waste and waste oil, which is a method for separating industrial grease and other impurities to be treated from food waste and waste oil, including: material receiving treatment, sorting treatment, and pulping treatment , deoiling treatment and overall deodorization treatment;

[0035] The steps of the receiving process are:

[0036] a. Bag-breaking treatment is first performed on the food waste. After the bag-breaking treatment, the water leached from the food waste is sent to the grit chamber, and the solid components of the waste are sent to sorting treatment;

[0037] b, the waste oil first flows into the storage tank through the vibrating screen, and the grease content data is obtained from the storage tank for reporting, and then the waste oil is sent to the grit chamber, wherein the sieve aperture of the vibrating screen ranges from 3-10mm;

[0038] The steps of the sorting process are:

[0039] a. The solid componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com