Stainless steel, preparation method and application

A stainless steel, unavoidable technology, applied in the field of preparation, stainless steel, to achieve the effect of shortening time, improving pitting corrosion resistance, and improving microbial corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

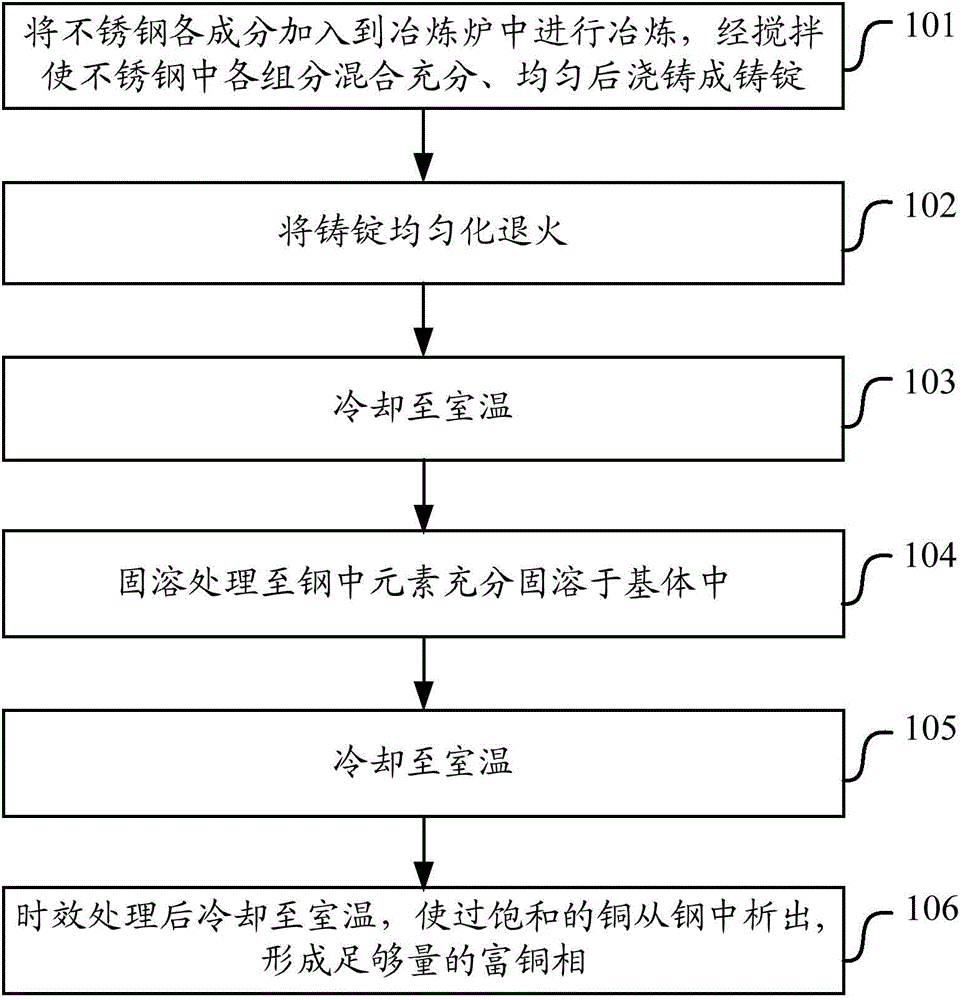

[0040] The embodiment of the present invention also provides a kind of preparation method of stainless steel, figure 1 A schematic diagram of the implementation process for the preparation method of stainless steel, such as figure 1 As shown, the steps can be included:

[0041] Step 101: adding the components of the stainless steel into a smelting furnace for smelting, mixing the components in the stainless steel fully and uniformly after stirring, and casting into an ingot;

[0042] Step 102: Homogenize the ingot annealing;

[0043] Step 103: cooling to room temperature after forging;

[0044] Step 104: solution treatment until the elements in the steel are fully dissolved in the matrix;

[0045] Step 105: cooling to room temperature;

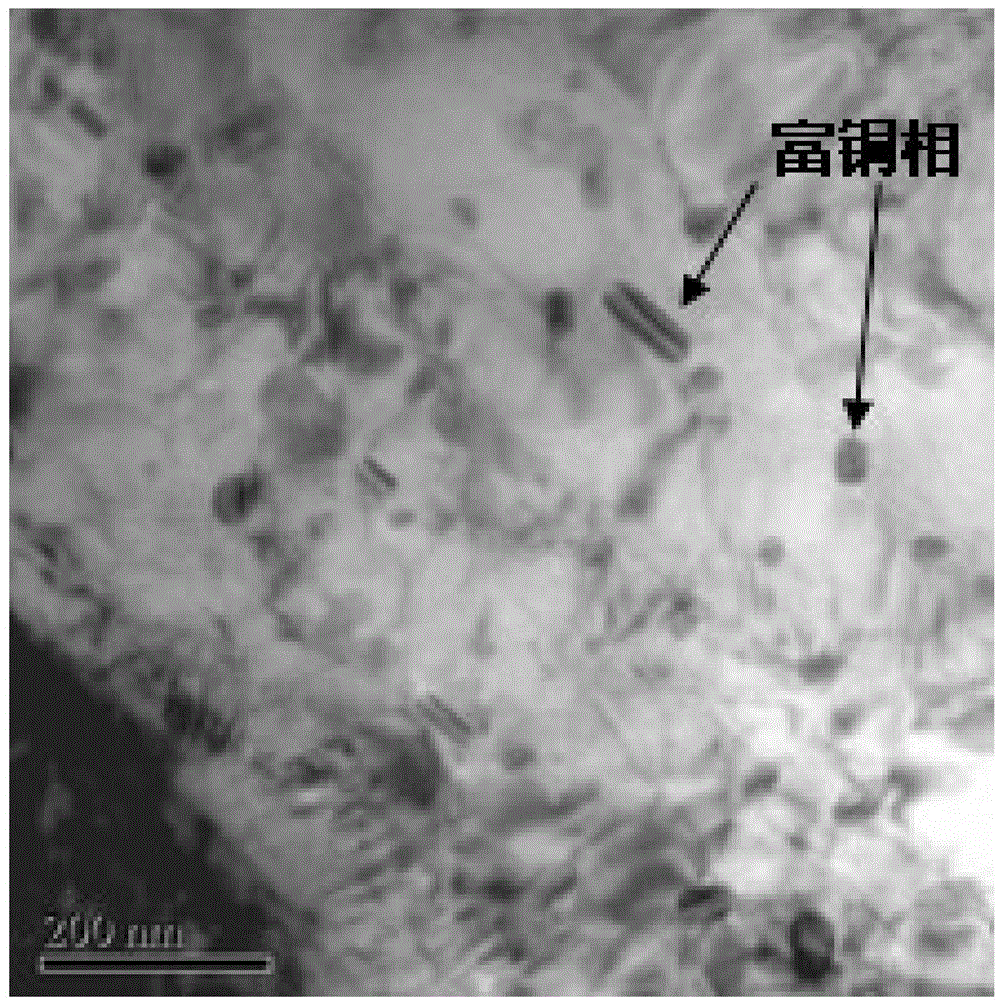

[0046] Step 106: cooling to room temperature after aging treatment, so that supersaturated copper is precipitated from the steel to form a sufficient amount of copper-rich phase.

[0047] During implementation, various components of stain...

Embodiment 1

[0067] Utilize vacuum induction smelting furnace to carry out the smelting of stainless steel of the present invention, concrete process is:

[0068] The alloy components are sequentially added to the vacuum induction smelting furnace, refined at 1480°C for 20 minutes, then magnetically stirred and cast into ingots;

[0069] After homogenization annealing at 1150°C for 2 hours, forging into rod or block samples;

[0070] Insulate at 1040°C for 0.5h, so that the copper, nitrogen and rare earth elements in the steel can be fully dissolved in the matrix;

[0071] After air cooling or water cooling to room temperature, the copper in the steel is in a supersaturated state;

[0072] Insulate at 700°C for 2 hours to allow the supersaturated copper to precipitate a sufficient amount of copper-rich phase from the steel;

[0073] Cool in air or water to room temperature.

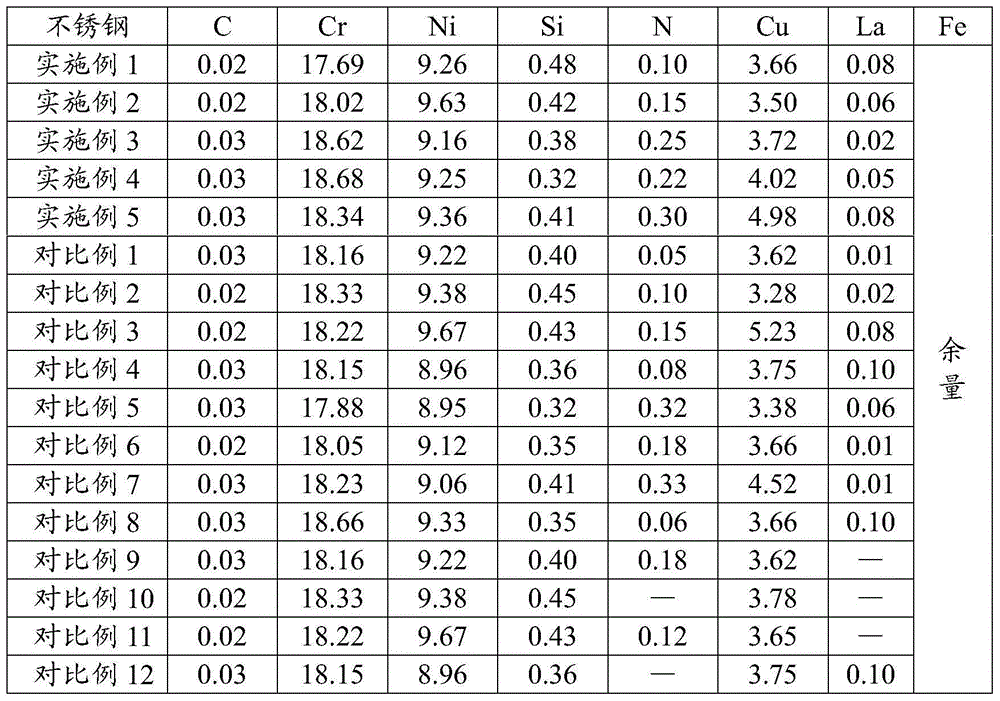

[0074] The chemical composition analysis results of the stainless steel in Example 1 above are shown in Table 1....

Embodiment 2

[0077] The difference from Example 1 is:

[0078] Utilize vacuum induction smelting furnace to carry out the smelting of stainless steel of the present invention, concrete process is:

[0079] The alloy components are sequentially added to the vacuum induction smelting furnace, refined at 1450°C for 15 minutes, then magnetically stirred and cast into ingots;

[0080] After homogenization annealing at 1100°C for 1.5 hours, forging into rod or block samples;

[0081] Insulate at 1030°C for 0.5h, so that the copper, nitrogen and rare earth elements in the steel can be fully dissolved in the matrix;

[0082] After air cooling or water cooling to room temperature, the copper in the steel is in a supersaturated state;

[0083] Insulate at 700°C for 2 hours to allow the supersaturated copper to precipitate a sufficient amount of copper-rich phase from the steel;

[0084] Cool in air or water to room temperature.

[0085] The chemical composition analysis results of the stainless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com