Vibrating device for acid pickling of steel wire rods

A vibration device and wire rod acid technology, which is applied in the field of wire rod pickling vibration device, can solve the problems of unclean cleaning of oxide skin on the surface of wire rod, easy corrosion pits on the surface of wire rod, broken wires in wire drawing process, etc., and speed up the chemical process. Effects of reaction rate, shortening of pickling time, and reduction of acid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

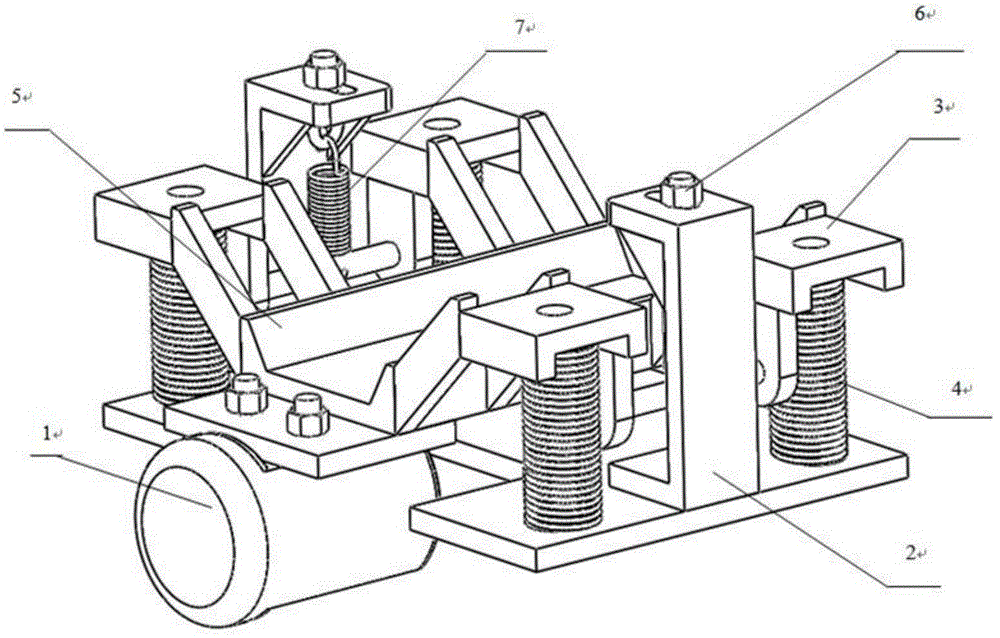

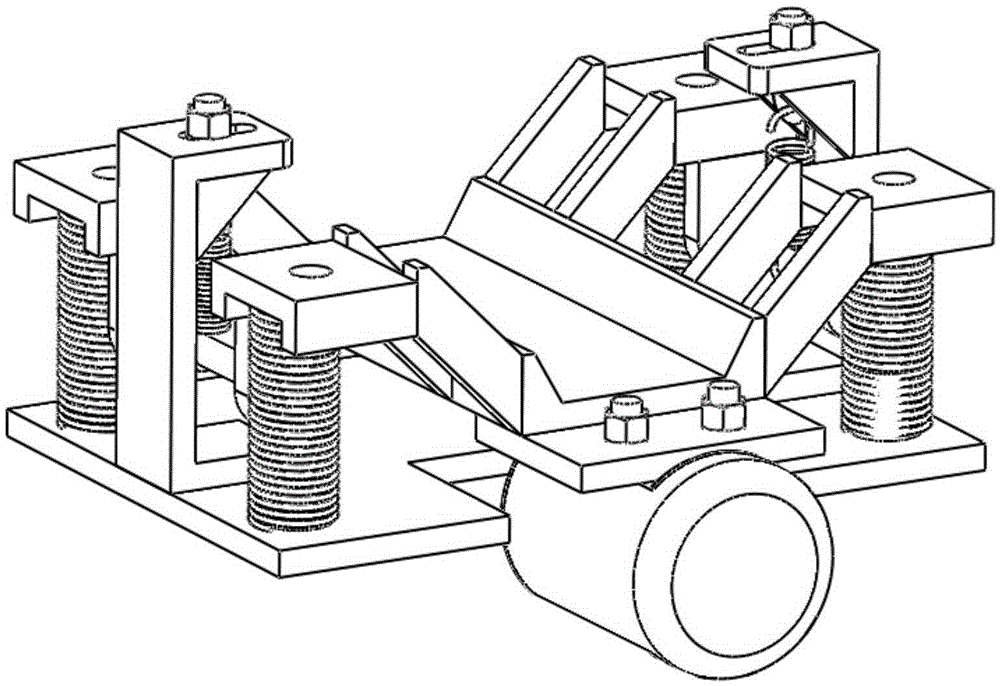

[0047] A wire rod pickling vibrating device, characterized in that it includes an active vibrator, a passive vibrator, and a crossbeam; the active vibrator and the passive vibrator are symmetrically arranged and connected by a crossbeam; the active vibrator is provided with There is a vibrating motor, which drives the active vibrator and the passive vibrator to vibrate together; the active vibrator is also provided with a spring group for controlling the amplitude, and a wire rod is installed on the beam.

Embodiment 2

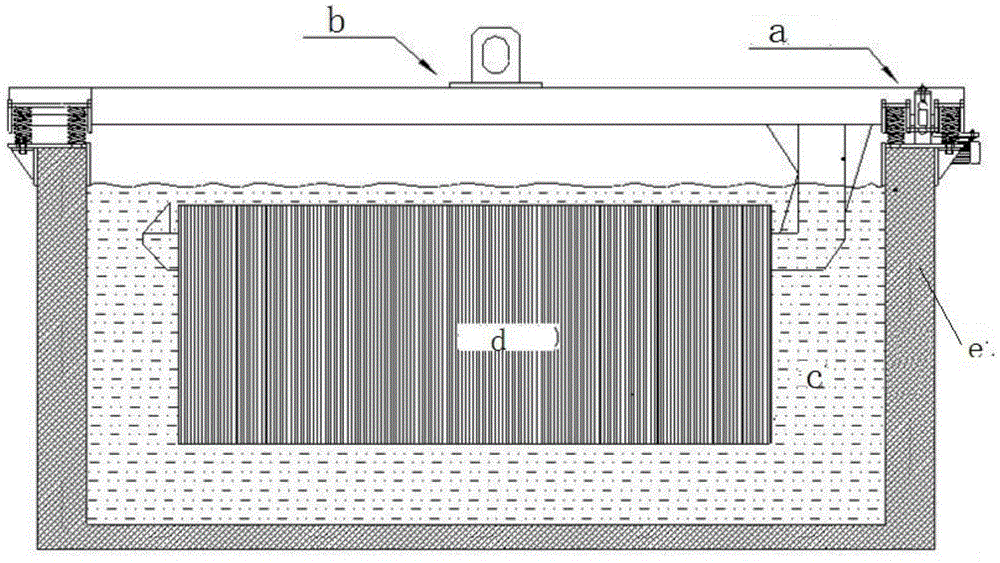

[0049] The difference from Embodiment 1 is that the active vibrator includes a vibration motor 1, a bracket 3 and a frame 2 as power, and the vibration motor 1 is installed on the bracket 3, and the bracket 3 is provided with Trapezoidal guide groove 5, the bottom of bracket 3 is provided with compression spring 4, and described bracket 3 is connected with frame 2 through tension spring 7, and the height of described tension spring 7 or compression spring 4 is adjustable; On the cement wall of the pickling tank, the frame 2 links to each other with the pressure spring 4 and the tension spring 7 of the bracket 3. The passive vibrator and the active vibrator are arranged symmetrically and connected through a trapezoidal guide groove; the wire rod d is placed on an h-shaped beam and placed in the trapezoidal guide groove of the bracket.

[0050] The present invention adopts the spring combination of the tension spring 7 and the pressure spring 4 arranged between the bracket 3 and...

Embodiment 3

[0053] The difference from Example 1 is that the passive vibrator and the active vibrator have the same structure except that they do not have a vibration motor, and they are installed on the cement wall of the pickling tank, opposite to the active vibrator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com