Novel neodymium iron boron magnet

A technology of NdFeB magnets, applied in the direction of magnetic objects, magnetic materials, permanent magnets, etc., can solve the problems of rust spots, no protective layer, and NdFeB magnets are easy to be corroded, and achieve the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

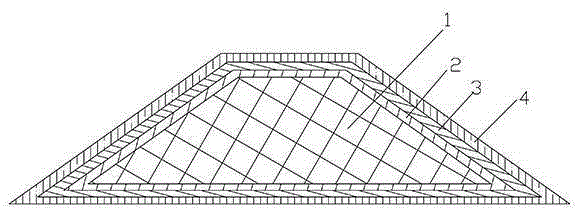

[0012] Such as figure 1 As shown, the novel NdFeB magnet provided in this embodiment includes an NdFeB substrate 1, and the outer surface of the NdFeB substrate 1 is sequentially provided with an electrical insulating coating 2, a corrosion-resistant layer 3 and a galvanized layer from the inside to the outside. 4. The electrical insulating coating 2 is a nano-silicon nitride coating with a thickness of 5 μm to 10 μm, and the corrosion-resistant layer 3 is an epoxy resin coating. The cross section of the NdFeB substrate 1 is trapezoidal. The thickness of the epoxy resin coating is 30 μm˜50 μm.

[0013] In order to obtain better dispersion performance of the nano-silicon nitride in the coating, thereby increasing the coating rate, the particle size of the nano-silicon nitride is 30nm-40nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The size of granule | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com