Fuel cell electrode structure and preparation method thereof

A fuel cell electrode and electrode structure technology, applied in the direction of fuel cells, battery electrodes, fuel cell parts, etc., can solve the problems of difficulty in ensuring the uniformity of the prepared frame, long-term curing of materials, and specific power reduction, etc., to achieve Effects of improving reliability and safety, increasing strength, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

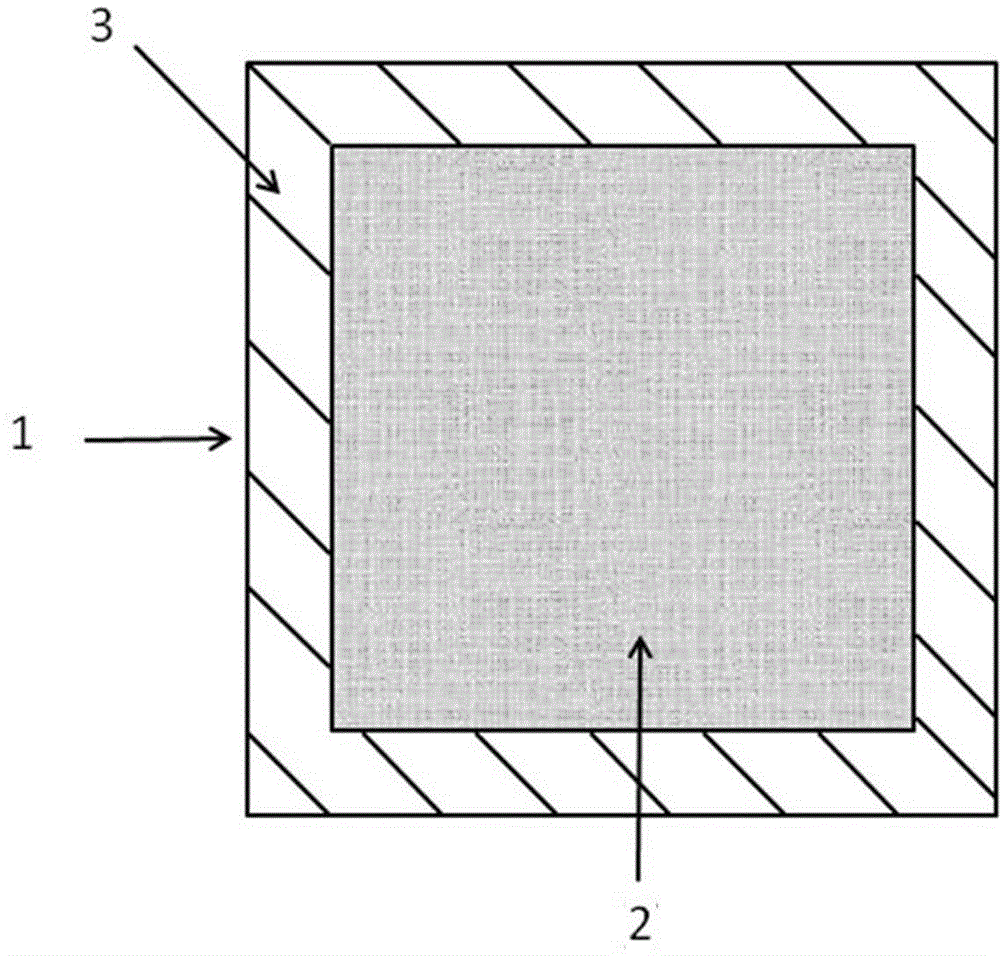

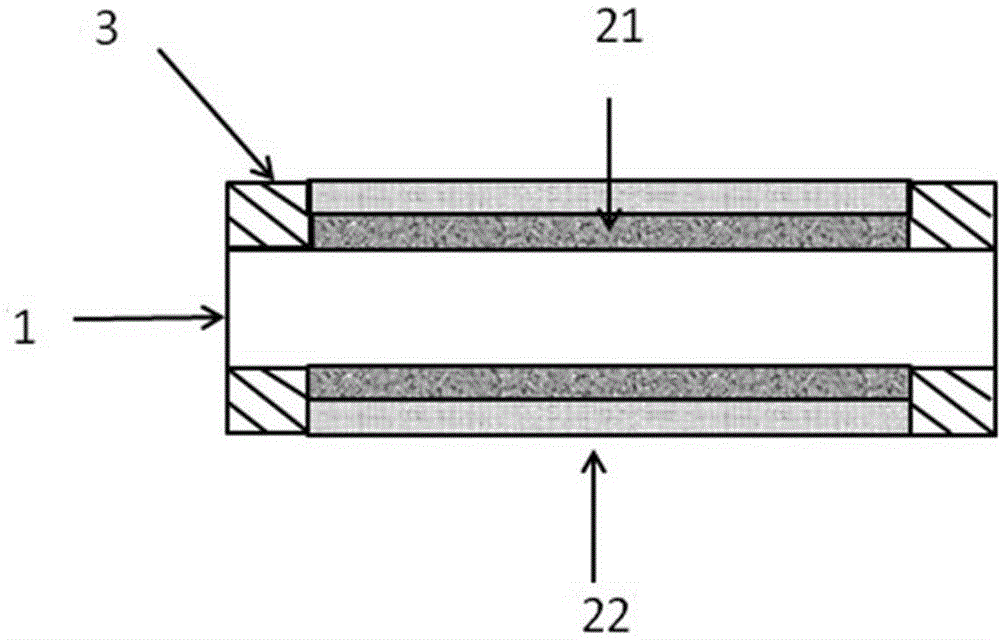

[0072] A fuel cell electrode structure comprising a frame region 3 and an active region 2 is prepared by the following method:

[0073] The fiber-reinforced composite sheet is cut into the shape of a picture frame. The fiber-reinforced composite can be glass fiber-reinforced epoxy resin composite (GRFC), and the sheet thickness can be 100 μm. The outer size of the picture frame is 100mm×100mm, and the inner size is 75mm×75mm. Cut two pieces.

[0074] The perfluorosulfonic acid proton membrane with a thickness of 28 μm was cut into a size of 100×100 mm.

[0075] The above two photo frame-shaped glass fiber reinforced epoxy resin composite materials were respectively placed on both sides of the perfluorosulfonic acid proton membrane and fixed.

[0076] Place the above positioned glass fiber reinforced epoxy resin composite material and perfluorosulfonic acid proton membrane in a press and heat press for 150s, wherein the temperature of the press is 130°C and the pressure is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com