Optical fluid three-color composite random laser

A random laser and optical fluid technology, applied in the field of lasers, can solve the problems of inability to operate for a long time, the quality of random lasers is degraded, and the reconfigurability is poor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

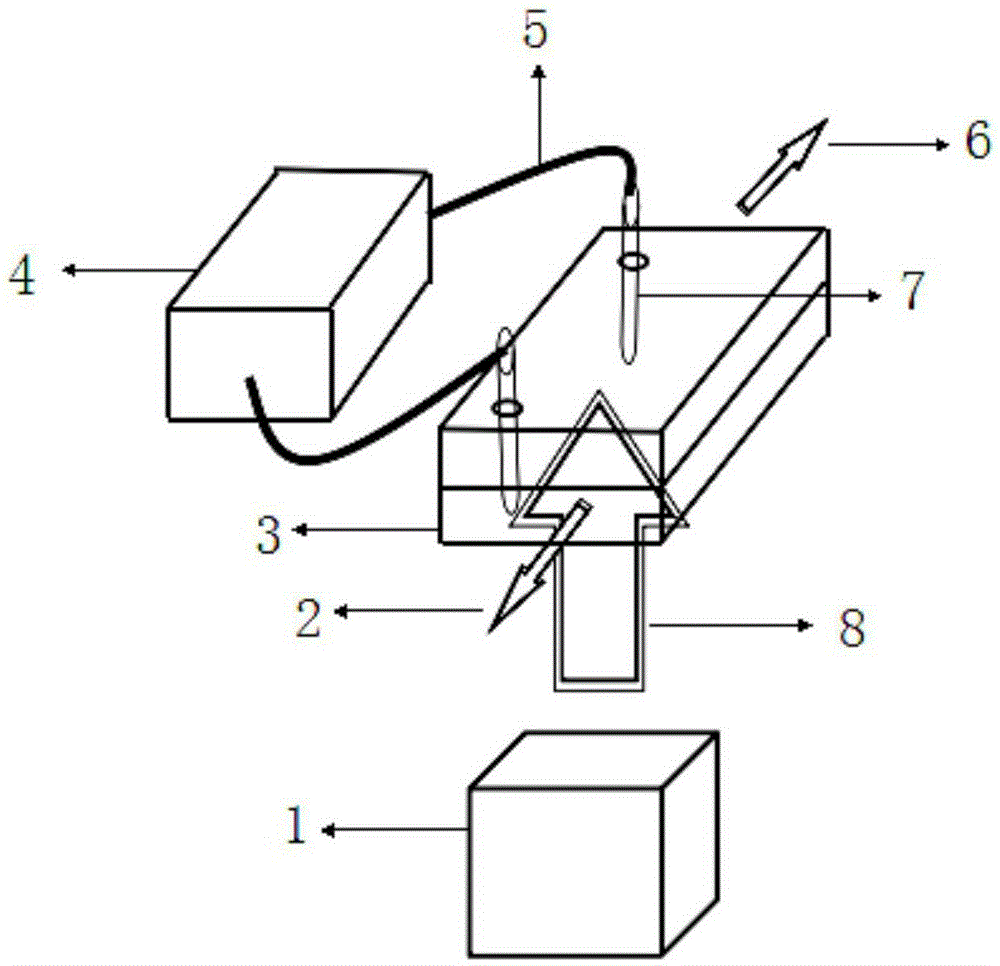

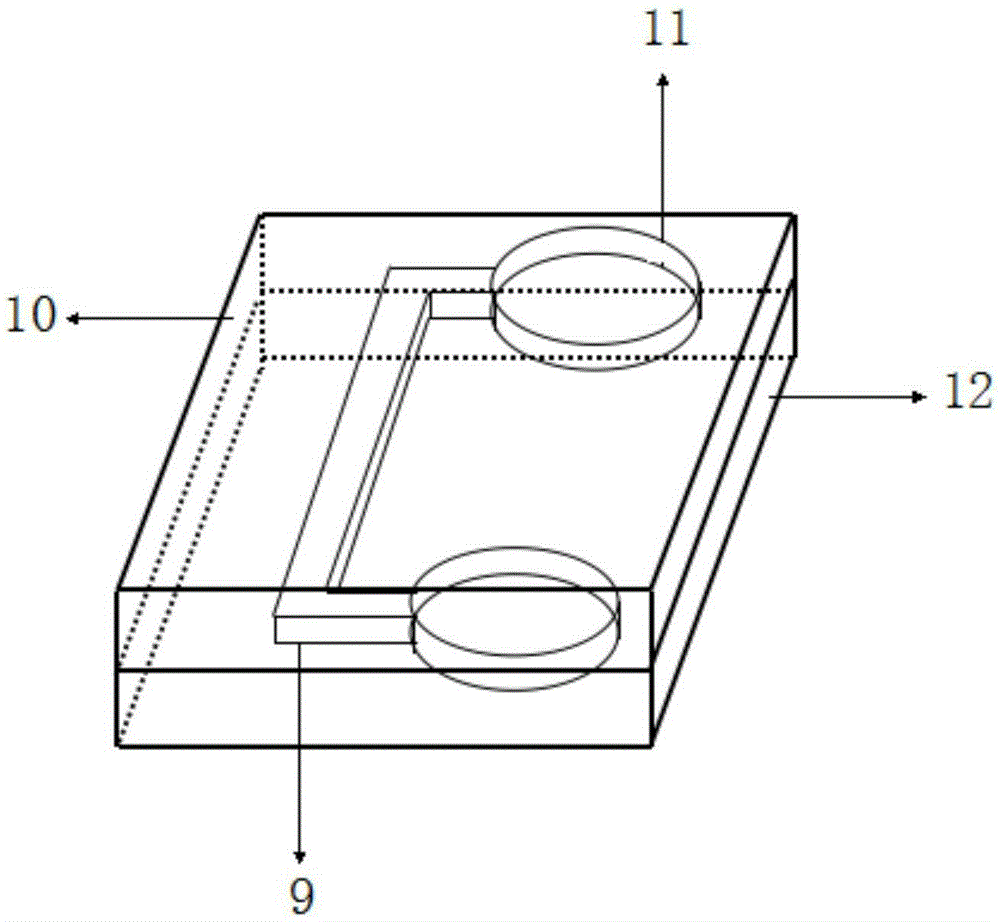

[0019] Embodiment 1: as figure 1 with 2 As shown, an optofluidic three-color composite random laser includes an external pumping optical path 1, a microfluidic chip 3 and a precision peristaltic pump 4, and the microfluidic chip 3 is formed by bonding a substrate 12 and a cover 10 , the substrate 12 is configured with a microfluidic channel 9, and the two ports of the microfluidic channel 9 are configured with columnar grooves 11, the grooves 11 communicate with the outer surface of the cover sheet 10, and are fluid inlets and outlets. The precision peristaltic The pump 4 is connected to the microfluidic channel 9 through the hollow stainless steel cylinder 7 and the PTFE hose 5 to form a fluid circuit and circulate the laser dye; Inside the channel 9, the outgoing light 2 and the outgoing light 6 of the microfluidic chip 3 are random lasers composed of three colors (red, green, blue).

[0020] The microfluidic chip 3 is constructed by molding. The transverse width and dept...

Embodiment 2

[0021] Embodiment 2: The three kinds of laser dyes are respectively 1.67mg / ml Coumarin 440 (Coumarin440), 0.417mg / ml Coumarin 153 (Coumarin153), 0.648mg / ml Oxazine 170 (Oxazine170), wherein Coumarin Element 440 (Coumarin440) emits blue light, Coumarin 153 (Coumarin153) emits green light, and oxazine 170 (Oxazine170) emits red light. After red, green, and blue are combined, the emitted light is a composite white random laser, and the rest is the same as in the embodiment. 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com