Frozen dried poultry egg product and making method thereof

A production method and a technology for dried poultry eggs, which are applied to the preservation of eggs by freezing/cooling, food freezing, food preservation, etc., can solve the problem of insufficient utilization of poultry eggs, and achieve the effect of increasing added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

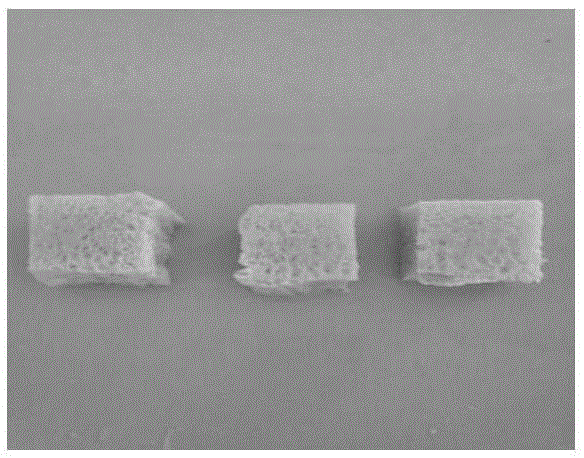

Image

Examples

Embodiment 1

[0048] Weigh 130g whole egg liquid and pasteurize it; weigh 17g water, add 1.5g salt, 0.8g soy sauce, 0.7g cooking wine, stir well to dissolve the salt, and mix the soy sauce and cooking wine evenly. Add the pasteurized whole egg mixture and beat well to combine. Then fill the mixed egg liquid into a PP material mold with a length of 115mm, a width of 90mm, and a height of 40mm, cover the top cover, place the mold in the molding pot, and adjust the molding parameters at a temperature of 90°C and a time of 30 minutes. After the molding is completed, the product is demolded while it is hot and placed on a cooling platform. After the product is cooled to room temperature, it is placed in a -18°C freezer for freezing and hardening. The freezing time is 8 hours. After the freezing process is completed, vacuum packaging can be carried out. If there is a requirement for the shape of the product, the product can be cut into corresponding states with a frozen meat cutting machine accor...

Embodiment 2

[0050] Weigh 150g whole egg liquid and pasteurize it; weigh 25g water, add 1.8g salt, 1.5g soy sauce, 0.8g cooking wine, stir well to dissolve the salt, and mix the soy sauce and cooking wine evenly. Add the pasteurized whole egg mixture and beat well to combine. Then fill the mixed egg liquid into a PP material mold with a length of 130mm, a width of 100mm, and a height of 50mm, cover the top cover, place the mold in the molding pot, and adjust the molding parameters at a temperature of 95°C and a time of 35 minutes. After the molding is completed, the product is demolded while it is hot and placed on a cooling platform. After the product is cooled to room temperature, it is placed in a -24°C freezer for freezing and hardening. The freezing time is 12 hours. After the freezing process is completed, vacuum packaging can be carried out. If there is a requirement for the shape of the product, the product can be cut into corresponding states with a frozen meat cutting machine acc...

Embodiment 3

[0052] Weigh 75g of egg liquid and pasteurize it; weigh 15g of water, add 1.2g of salt, 0.5g of soy sauce, and 0.6g of cooking wine, stir well to dissolve the salt, and mix the soy sauce and cooking wine evenly. Add the pasteurized whole egg mixture and beat well to combine. Then fill the mixed egg liquid into a PP material mold with a length of 90mm, a width of 80mm, and a height of 30mm, cover the top cover, place the mold in the molding pot, and adjust the molding parameters at a temperature of 85°C and a time of 25 minutes. After the molding is completed, the product is demolded while it is hot and placed on a cooling platform. After the product is cooled to room temperature, it is placed in a -20°C freezer for freezing and hardening. The freezing time is 10 hours. After the freezing process is completed, vacuum packaging can be carried out. If there is a requirement for the shape of the product, the product can be cut into corresponding states with a frozen meat cutting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com