MOFs material capable of effectively separating acetylene mixed gas and preparation method of MOFs material

A technology of mixing gas and acetylene, applied in the field of chemistry, can solve the problems of waste, increased cost, low separation selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A preparation method of MOFs material for effectively separating acetylene / ethylene and acetylene / carbon dioxide mixed gas, comprising the following steps:

[0044] 1) Add a certain proportion of mixed solvent of DMA and water into the glass bottle, and then dissolve 5-(4-hydrogen-1,2,4-triazol-4-yl)-1,3-phthalic acid in the above Add a certain amount of copper salt to the mixture of DMA and water, and ultrasonicate for 5 to 15 minutes;

[0045] Among them, the volume ratio of DMA and water is 1:0.5~2,5-(4-hydrogen-1,2,4-triazol-4-yl)-1,3-benzenedicarboxylic acid, DMA and water mixed solvent The ratio of the amount of substance is 1:1433~3656, the ratio of the amount of copper salt to 5-(4-hydrogen-1,2,4-triazol-4-yl)-1,3-benzenedicarboxylic acid 1:1~4;

[0046] 2) Screw the cap on the glass bottle to seal it, then place it in an oven, and heat it from room temperature to 75-100°C;

[0047] 3) At the above-mentioned temperature of 75-100°, keep warm for 24-36 hours, ...

Embodiment 1

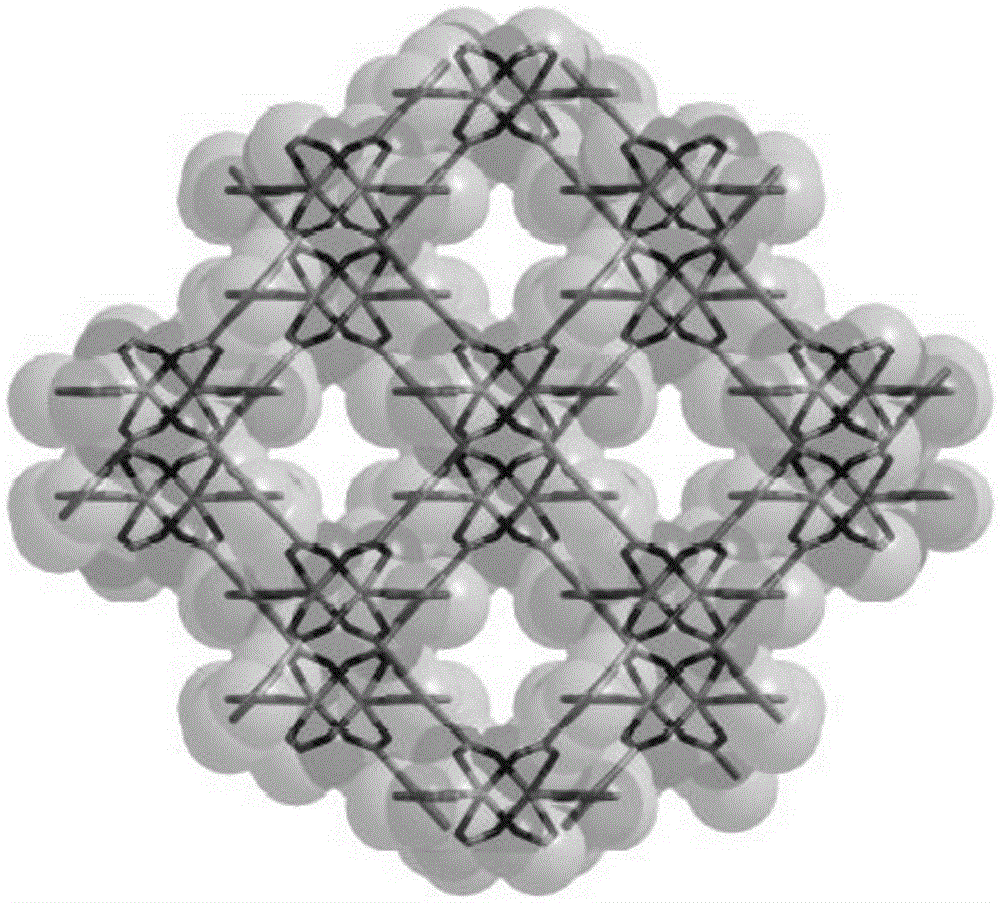

[0051] 1. [Cu(5TIA)]·(DMA)(H 2 O) 1.5 Preparation of materials:

[0052] (1) Dissolve 0.023 g of 5-(4-hydrogen-1,2,4-triazol-4-yl)-1,3-benzenedicarboxylic acid in N,N-dimethylacetamide (DMA) and Add 0.0095g of cuprous iodide to the water mixture (5mL, v:v=3:2), and sonicate for 10 minutes;

[0053] (2) Screw the cap on the glass bottle to seal it, then place it in an oven and heat it from room temperature to 85°C;

[0054] (3) Maintain 85°C, keep warm for 24 hours, take out the glass bottle, and cool to room temperature;

[0055] (4) Filter the solution in the glass bottle, wash the product with N,N-dimethylacetamide, and dry the product naturally at room temperature to obtain green blocky crystals;

[0056] 2. [Cu(5TIA)]·(DMA)(H 2 O) 1.5 Preparation of FJU-22 material by activation:

[0057] The prepared crystals were exchanged several times with methanol and dichloromethane respectively, and placed under the conditions of 60°C and 5μmHg to remove the solvent molecules...

Embodiment 2

[0059] 1. [Cu(5TIA)]·(DMA)(H 2 O) 1.5 Preparation of materials:

[0060] (1) Dissolve 0.023 g of 5-(4-hydrogen-1,2,4-triazol-4-yl)-1,3-benzenedicarboxylic acid in N,N-dimethylacetamide (DMA) and Add 0.017g of copper chloride dihydrate to the water mixture (5mL, v:v=3:3), and ultrasonicate for 15 minutes;

[0061] (2) Screw the cap on the glass bottle to seal it, then place it in an oven and heat it from room temperature to 75°C;

[0062] (3) Maintain 75°C for 24 hours, take out the glass bottle, and cool to room temperature;

[0063] (4) Filter the solution in the glass bottle, wash the product with N,N-dimethylacetamide, and dry the product naturally at room temperature to obtain green blocky crystals;

[0064] 2. [Cu(5TIA)]·(DMA)(H 2 O) 1.5 Preparation of FJU-22 material by activation:

[0065] The prepared crystals were exchanged with methanol several times, and placed under the conditions of 60°C and 5 μmHg to remove solvent molecules, and the activated FJU-22 new m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com