Method for efficiently preparing ex-situ presulfuration agent through medium-pressure solvothermal method

A solvothermal method and vulcanizing agent technology, applied in the preparation of sulfides, hydrogenated polysulfides/polysulfides, organic chemistry, etc., can solve the problems of high toxicity, low sulfur content and high cost of pre-vulcanizing agents, and avoid Concentrated exothermic phenomenon, high sulfur content, low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Sulfurene ratio 2.5:1.

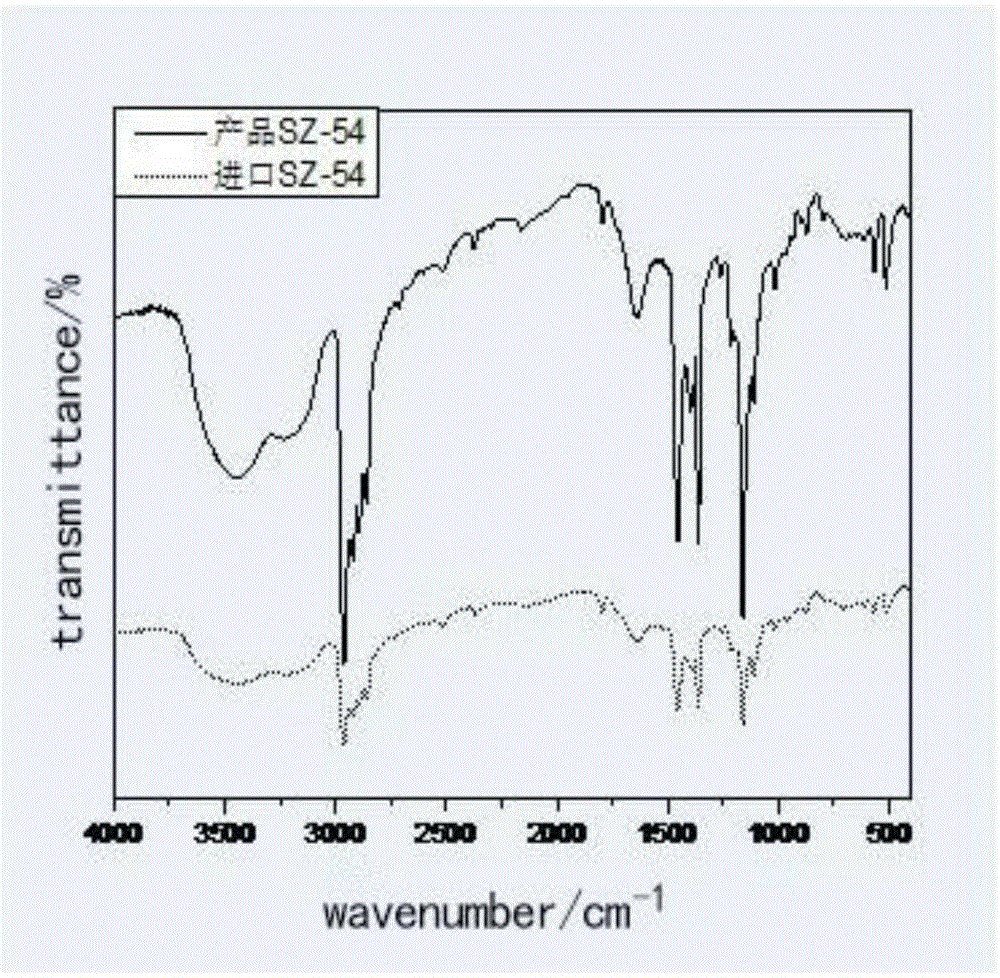

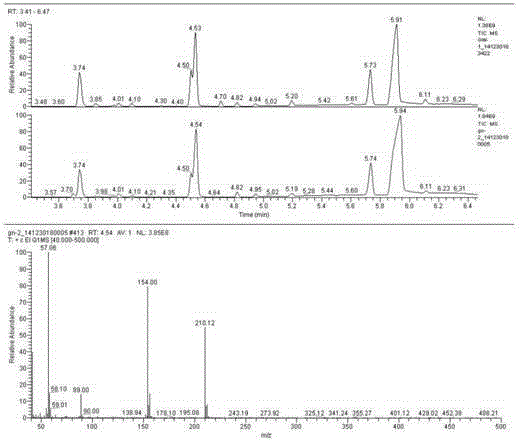

[0027] Add 17.86kg of elemental sulfur and 18.00kg of ammonia solvent with a mass fraction of 5% to the reactor, raise the temperature to 150°C, slowly add 12.50kg of isobutylene, and keep the pressure at 3.0-3.5MPa. Continue to react for 6h after adding, and then After cooling to 35°C, the mixture was forced out of the reaction vessel using residual pressure. The mixture was allowed to stand for liquid separation, and the organic phase was filtered, washed, and distilled to obtain the product of an external organic presulfurizing agent with a yield of 90%. After analyzing the ammonia concentration of the inorganic phase, add fresh ammonia water to make it reach the original concentration before recycling. The product obtained in this embodiment is compared and analyzed with the imported vulcanizing agent to obtain a total ion chromatogram (TIC) and a mass spectrogram (MS) (see figure 2 ), infrared spectrum (see image 3 ).

[0028] The spe...

Embodiment 2

[0031] Sulfurene ratio 2.5:1.

[0032] Add 17.86kg of elemental sulfur and 27.00kg of ammonia solvent with a mass fraction of 10% to the reactor, raise the temperature to 145°C, slowly add 12.50kg of isobutylene, and keep the pressure at 3.0-3.5MPa. Continue to react for 6 hours after adding, and then After cooling to 35°C, the mixture was forced out of the reaction vessel using residual pressure. The mixture was allowed to stand for liquid separation, and the organic phase was filtered, washed, and distilled to obtain the product of an external organic presulfurizing agent with a yield of 74%. After analyzing the ammonia concentration of the inorganic phase, add fresh ammonia water to make it reach the original concentration before recycling.

[0033] The specifications and parameters of the synthesized external organic prevulcanizing agent are as follows:

[0034]

Embodiment 3

[0036] Sulfurene ratio 2.0:1.

[0037] Add 14.29kg of elemental sulfur and 36.00kg of ammonia solvent with a mass fraction of 5% to the reactor, raise the temperature to 155°C, slowly add 12.5kg of isobutylene, and keep the pressure at 3.0-3.5MPa. Continue the reaction for 6 hours after the addition, and then After cooling to 35°C, the mixture was forced out of the reaction vessel using residual pressure. The mixture was allowed to stand for liquid separation, and the organic phase was filtered, washed, and distilled to obtain the product of an external organic presulfurizing agent with a yield of 81%. After analyzing the ammonia concentration of the inorganic phase, add fresh ammonia water to make it reach the original concentration before recycling.

[0038] The specifications and parameters of the synthesized external organic prevulcanizing agent are as follows:

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com